What is Global SiC Device Foundry Market?

The Global SiC Device Foundry Market refers to the industry focused on the production and supply of silicon carbide (SiC) devices, which are essential components in various high-performance applications. Silicon carbide is a semiconductor material known for its superior properties, such as high thermal conductivity, high electric field breakdown strength, and high-temperature stability, making it ideal for use in power electronics. The foundry market involves companies that manufacture SiC devices for other companies, which design and market the final products. This market is crucial as it supports the growing demand for energy-efficient and high-performance electronic devices across various sectors, including automotive, renewable energy, and industrial applications. The foundry model allows companies to leverage specialized manufacturing capabilities without investing in their own production facilities, thus accelerating innovation and reducing time-to-market for new technologies. As industries continue to seek more efficient and robust solutions, the Global SiC Device Foundry Market is poised to play a pivotal role in meeting these demands by providing the necessary infrastructure and expertise for SiC device production.

in the Global SiC Device Foundry Market:

The Global SiC Device Foundry Market caters to a diverse range of applications, each requiring specific types of silicon carbide devices to meet their unique needs. In the automotive sector, particularly in electric vehicles (EVs) and hybrid electric vehicles (HEVs), SiC devices are used to enhance the efficiency and performance of powertrains. These devices help in reducing energy losses and improving the overall range of the vehicles. SiC MOSFETs and diodes are commonly used in inverters and onboard chargers, providing faster switching speeds and higher thermal conductivity compared to traditional silicon-based devices. In the realm of EV charging, SiC devices are crucial for developing fast-charging stations. They enable higher power density and efficiency, allowing for quicker charging times and reduced energy consumption. This is particularly important as the demand for EVs continues to rise, necessitating the development of an extensive and efficient charging infrastructure. Uninterruptible Power Supplies (UPS) also benefit from SiC technology. SiC devices enhance the efficiency and reliability of UPS systems, which are critical in providing backup power during outages. The high efficiency of SiC devices reduces energy losses and heat generation, leading to more compact and reliable UPS solutions. Data centers and servers, which require significant amounts of power, utilize SiC devices to improve energy efficiency and reduce operational costs. SiC-based power supplies and converters help in minimizing energy losses and managing heat dissipation, which is crucial for maintaining the performance and longevity of data center equipment. In the photovoltaic (PV) industry, SiC devices are used in solar inverters to convert the direct current (DC) generated by solar panels into alternating current (AC) for use in the grid. The high efficiency and reliability of SiC devices contribute to maximizing the energy yield from solar installations. Energy storage systems, which are essential for balancing supply and demand in renewable energy applications, also benefit from SiC technology. SiC devices improve the efficiency and performance of battery management systems, enabling better energy conversion and storage capabilities. Wind power generation, another key area of renewable energy, utilizes SiC devices in power converters to enhance the efficiency and reliability of wind turbines. The robust nature of SiC devices allows them to withstand harsh environmental conditions, making them ideal for use in wind power applications. Beyond these specific applications, SiC devices are also used in various other industries, including aerospace, industrial automation, and telecommunications, where high efficiency and reliability are paramount. The versatility and superior performance characteristics of SiC devices make them a preferred choice for a wide range of applications, driving the growth of the Global SiC Device Foundry Market.

Automotive & EV/HEV, EV Charging, UPS, Data Center & Server, PV, Energy Storage, Wind Power, Others in the Global SiC Device Foundry Market:

The usage of SiC devices in the Global SiC Device Foundry Market spans several critical areas, each benefiting from the unique properties of silicon carbide technology. In the automotive industry, particularly in electric vehicles (EVs) and hybrid electric vehicles (HEVs), SiC devices are pivotal in enhancing the efficiency and performance of powertrains. They are used in inverters and onboard chargers, where their ability to operate at higher temperatures and voltages allows for more compact and efficient designs. This results in improved vehicle range and reduced energy consumption, addressing key challenges in the EV market. In the realm of EV charging, SiC devices are instrumental in developing fast-charging stations. Their high power density and efficiency enable quicker charging times, which is crucial for the widespread adoption of electric vehicles. As the demand for EVs grows, the need for efficient and reliable charging infrastructure becomes increasingly important, and SiC technology plays a vital role in meeting this demand. Uninterruptible Power Supplies (UPS) also benefit from SiC technology. SiC devices enhance the efficiency and reliability of UPS systems, which are critical in providing backup power during outages. The high efficiency of SiC devices reduces energy losses and heat generation, leading to more compact and reliable UPS solutions. Data centers and servers, which require significant amounts of power, utilize SiC devices to improve energy efficiency and reduce operational costs. SiC-based power supplies and converters help in minimizing energy losses and managing heat dissipation, which is crucial for maintaining the performance and longevity of data center equipment. In the photovoltaic (PV) industry, SiC devices are used in solar inverters to convert the direct current (DC) generated by solar panels into alternating current (AC) for use in the grid. The high efficiency and reliability of SiC devices contribute to maximizing the energy yield from solar installations. Energy storage systems, which are essential for balancing supply and demand in renewable energy applications, also benefit from SiC technology. SiC devices improve the efficiency and performance of battery management systems, enabling better energy conversion and storage capabilities. Wind power generation, another key area of renewable energy, utilizes SiC devices in power converters to enhance the efficiency and reliability of wind turbines. The robust nature of SiC devices allows them to withstand harsh environmental conditions, making them ideal for use in wind power applications. Beyond these specific applications, SiC devices are also used in various other industries, including aerospace, industrial automation, and telecommunications, where high efficiency and reliability are paramount. The versatility and superior performance characteristics of SiC devices make them a preferred choice for a wide range of applications, driving the growth of the Global SiC Device Foundry Market.

Global SiC Device Foundry Market Outlook:

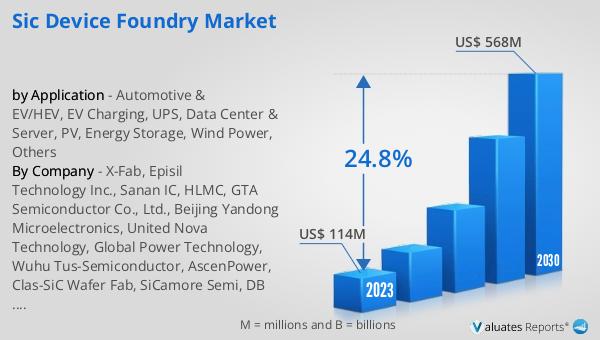

The global market for SiC Device Foundry was valued at $150 million in 2024, and it is anticipated to expand significantly, reaching an estimated size of $695 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 24.8% over the forecast period. This impressive growth rate underscores the increasing demand for silicon carbide devices across various industries, driven by their superior performance characteristics compared to traditional silicon-based devices. The market's expansion is fueled by the rising adoption of SiC technology in sectors such as automotive, renewable energy, and industrial applications, where efficiency and reliability are critical. As industries continue to seek more efficient and robust solutions, the Global SiC Device Foundry Market is poised to play a pivotal role in meeting these demands by providing the necessary infrastructure and expertise for SiC device production. The foundry model allows companies to leverage specialized manufacturing capabilities without investing in their own production facilities, thus accelerating innovation and reducing time-to-market for new technologies. As the market continues to evolve, the Global SiC Device Foundry Market is expected to witness significant advancements, further driving its growth and adoption across various sectors.

| Report Metric | Details |

| Report Name | SiC Device Foundry Market |

| Accounted market size in year | US$ 150 million |

| Forecasted market size in 2031 | US$ 695 million |

| CAGR | 24.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | X-Fab, Episil Technology Inc., Sanan IC, HLMC, GTA Semiconductor Co., Ltd., Beijing Yandong Microelectronics, United Nova Technology, Global Power Technology, Wuhu Tus-Semiconductor, AscenPower, Clas-SiC Wafer Fab, SiCamore Semi, DB HiTek, Nanjing Quenergy Semiconductor, by Technology, SiC MOSFET, SiC SBD |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |