What is Global High Purity PBN Crucible Market?

The Global High Purity PBN Crucible Market is a specialized segment within the materials industry, focusing on the production and distribution of crucibles made from pyrolytic boron nitride (PBN). These crucibles are renowned for their exceptional purity, thermal stability, and chemical inertness, making them indispensable in high-tech applications. PBN crucibles are manufactured through a chemical vapor deposition process, resulting in a material that can withstand extreme temperatures and corrosive environments. This market caters primarily to industries that require high precision and reliability, such as semiconductor manufacturing, photovoltaics, and organic light-emitting diodes (OLEDs). The demand for high purity PBN crucibles is driven by the increasing complexity and miniaturization of electronic components, which necessitate materials that can maintain integrity under stringent conditions. As technology continues to advance, the need for high-performance materials like PBN crucibles is expected to grow, further solidifying their role in cutting-edge industrial applications. The market is characterized by a focus on innovation and quality, with manufacturers striving to meet the evolving needs of their clients through continuous research and development.

Size≤500cc, Size>500cc in the Global High Purity PBN Crucible Market:

In the Global High Purity PBN Crucible Market, the size of the crucibles plays a crucial role in determining their application and suitability for various industrial processes. Crucibles with a size of ≤500cc are typically used in applications where precision and control are paramount. These smaller crucibles are ideal for laboratory settings and small-scale production processes, where the amount of material being processed is limited, and the need for accuracy is high. They are often employed in research and development environments, where new materials and processes are being tested and refined. The compact size of these crucibles allows for efficient heat transfer and uniform temperature distribution, which are critical factors in achieving consistent results. On the other hand, crucibles with a size of >500cc are designed for larger-scale industrial applications. These larger crucibles are used in processes that require the handling of greater volumes of material, such as in the production of semiconductors and photovoltaic cells. The increased capacity of these crucibles allows for the processing of larger batches, improving efficiency and throughput in manufacturing operations. The choice between ≤500cc and >500cc crucibles depends largely on the specific requirements of the application, including the volume of material to be processed, the desired level of precision, and the operational scale of the production process. Manufacturers in the Global High Purity PBN Crucible Market must consider these factors when designing and producing crucibles to ensure they meet the diverse needs of their clients. The ability to offer a range of sizes and capacities is a key competitive advantage in this market, as it allows manufacturers to cater to a wide array of applications and industries. Additionally, the development of new technologies and processes continues to drive demand for both small and large crucibles, as industries seek to optimize their operations and improve the quality of their products. As a result, the Global High Purity PBN Crucible Market is characterized by a dynamic interplay between innovation, customization, and scalability, with manufacturers striving to deliver solutions that meet the evolving needs of their customers.

Photovoltaics Cells, Semiconductor, OLED, Others in the Global High Purity PBN Crucible Market:

The usage of Global High Purity PBN Crucibles spans several high-tech industries, each with its unique requirements and challenges. In the field of photovoltaics, PBN crucibles are essential for the production of high-efficiency solar cells. The purity and thermal stability of PBN make it an ideal material for the growth of silicon and other semiconductor materials used in solar cells. These crucibles ensure that the materials are free from contamination, which is crucial for achieving high conversion efficiencies in solar panels. In the semiconductor industry, PBN crucibles are used in the fabrication of integrated circuits and other electronic components. The ability of PBN to withstand high temperatures and corrosive environments makes it indispensable in processes such as chemical vapor deposition and epitaxial growth, where precise control over material properties is required. The use of PBN crucibles in these processes helps to ensure the quality and reliability of semiconductor devices, which are critical for the performance of electronic products. In the OLED industry, PBN crucibles are used in the deposition of organic materials that form the light-emitting layers of OLED displays. The high purity of PBN is essential for preventing contamination of the organic materials, which can affect the performance and lifespan of OLED displays. The use of PBN crucibles in OLED production helps to ensure the uniformity and consistency of the light-emitting layers, resulting in displays with vibrant colors and high contrast ratios. Beyond these specific industries, PBN crucibles are also used in a variety of other applications where high purity and thermal stability are required. These include the production of advanced ceramics, the growth of single crystals for scientific research, and the development of new materials for emerging technologies. The versatility and reliability of PBN crucibles make them a valuable tool in the pursuit of innovation and excellence across a wide range of fields. As industries continue to push the boundaries of what is possible, the demand for high-performance materials like PBN crucibles is expected to grow, driving further advancements in technology and manufacturing.

Global High Purity PBN Crucible Market Outlook:

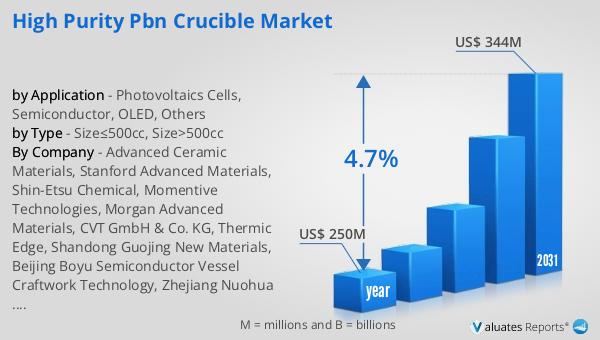

The outlook for the Global High Purity PBN Crucible Market indicates a promising trajectory. In 2024, the market was valued at approximately US$ 250 million. Projections suggest that by 2031, this figure will rise to an estimated US$ 344 million, reflecting a compound annual growth rate (CAGR) of 4.7% over the forecast period. This growth is indicative of the increasing demand for high purity PBN crucibles across various high-tech industries. The market's expansion is driven by the continuous advancements in technology, which necessitate materials that can withstand extreme conditions and maintain high levels of purity. As industries such as semiconductors, photovoltaics, and OLEDs continue to evolve, the need for reliable and high-performance materials like PBN crucibles becomes more pronounced. Manufacturers in this market are focused on innovation and quality, striving to meet the diverse needs of their clients through ongoing research and development. The ability to offer a range of sizes and capacities is a key competitive advantage, allowing manufacturers to cater to a wide array of applications and industries. As the market continues to grow, it presents opportunities for companies to expand their product offerings and enhance their market presence. The Global High Purity PBN Crucible Market is poised for continued growth, driven by the increasing complexity and miniaturization of electronic components and the ongoing pursuit of innovation in high-tech industries.

| Report Metric | Details |

| Report Name | High Purity PBN Crucible Market |

| Accounted market size in year | US$ 250 million |

| Forecasted market size in 2031 | US$ 344 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Advanced Ceramic Materials, Stanford Advanced Materials, Shin-Etsu Chemical, Momentive Technologies, Morgan Advanced Materials, CVT GmbH & Co. KG, Thermic Edge, Shandong Guojing New Materials, Beijing Boyu Semiconductor Vessel Craftwork Technology, Zhejiang Nuohua Ceramic, Yantai Hefuxiang Ceramics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |