What is Global Dual Arm Wafer Robot Market?

The Global Dual Arm Wafer Robot Market is a specialized segment within the broader robotics and semiconductor manufacturing industry. These robots are designed to handle wafers, which are thin slices of semiconductor material used in electronics for the fabrication of integrated circuits and other microdevices. Dual arm wafer robots are equipped with two arms, allowing them to perform complex tasks with greater efficiency and precision compared to single-arm robots. They are essential in semiconductor manufacturing processes, where precision and speed are critical. These robots help in automating the handling of wafers, reducing the risk of contamination and damage, and increasing throughput in production lines. The market for these robots is driven by the growing demand for semiconductors in various applications, including consumer electronics, automotive, and telecommunications. As technology advances, the need for more sophisticated and efficient manufacturing processes increases, further propelling the demand for dual arm wafer robots. The market is characterized by continuous innovation, with manufacturers focusing on enhancing the capabilities of these robots to meet the evolving needs of the semiconductor industry.

Atmospheric Type, Vacuum Type in the Global Dual Arm Wafer Robot Market:

In the Global Dual Arm Wafer Robot Market, two primary types of robots are utilized: Atmospheric Type and Vacuum Type. Atmospheric dual arm wafer robots operate in environments where the pressure is similar to the Earth's atmosphere. These robots are typically used in processes where wafers are exposed to air, such as during the initial stages of semiconductor manufacturing or in processes that do not require a vacuum environment. They are designed to handle wafers delicately, ensuring minimal contact and reducing the risk of contamination. The atmospheric type is often favored for its cost-effectiveness and ease of integration into existing manufacturing lines. On the other hand, Vacuum Type dual arm wafer robots are used in environments where wafers need to be processed in a vacuum. This is crucial in many semiconductor manufacturing processes, such as etching and deposition, where the presence of air can interfere with the process and affect the quality of the final product. Vacuum robots are designed to operate in low-pressure environments, ensuring that wafers are handled with precision and care. They are equipped with specialized grippers and sensors to maintain the integrity of the wafers during transfer. The choice between atmospheric and vacuum types depends on the specific requirements of the manufacturing process. Manufacturers often invest in vacuum robots for processes that demand high precision and cleanliness, despite their higher cost compared to atmospheric robots. The development of these robots involves advanced engineering to ensure they can withstand the harsh conditions of vacuum environments while maintaining high performance. Both types of robots play a crucial role in the semiconductor manufacturing process, contributing to the efficiency and quality of production. As the demand for semiconductors continues to rise, the need for both atmospheric and vacuum dual arm wafer robots is expected to grow, driving innovation and advancements in this market segment.

Semiconductor, Others in the Global Dual Arm Wafer Robot Market:

The Global Dual Arm Wafer Robot Market finds significant applications in the semiconductor industry and other sectors. In the semiconductor industry, these robots are indispensable for automating the handling of wafers throughout the manufacturing process. They are used in various stages, including wafer loading and unloading, inspection, and transfer between different processing stations. The precision and speed of dual arm wafer robots help in reducing cycle times and increasing throughput, which is crucial in meeting the high demand for semiconductors. These robots also minimize the risk of contamination and damage to the wafers, ensuring high-quality output. Beyond the semiconductor industry, dual arm wafer robots are also used in other sectors that require precise handling of delicate materials. For instance, they are employed in the production of solar panels, where they handle thin silicon wafers used in photovoltaic cells. The robots' ability to operate in both atmospheric and vacuum environments makes them versatile tools in various manufacturing processes. Additionally, they are used in research and development settings, where precision and repeatability are essential. The versatility and efficiency of dual arm wafer robots make them valuable assets in any industry that requires the handling of delicate materials. As industries continue to seek automation solutions to improve efficiency and reduce costs, the demand for dual arm wafer robots is expected to grow. This growth is driven by the increasing complexity of manufacturing processes and the need for high precision and reliability. The continuous advancements in robotics technology also contribute to the expanding applications of dual arm wafer robots, making them an integral part of modern manufacturing.

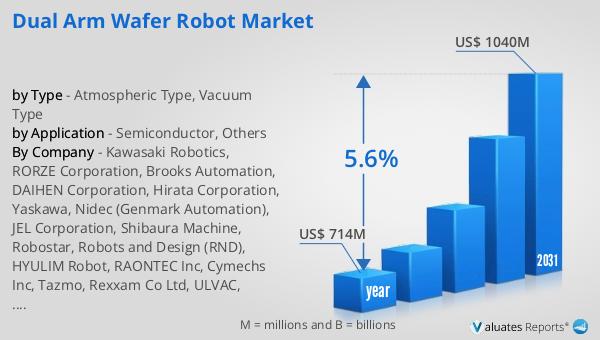

Global Dual Arm Wafer Robot Market Outlook:

The global market for Dual Arm Wafer Robots was valued at $714 million in 2024, and it is anticipated to expand to a revised size of $1,040 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.6% during the forecast period. This growth trajectory underscores the increasing demand for these sophisticated robots in the semiconductor industry and beyond. The rising need for automation in manufacturing processes, coupled with the growing complexity of semiconductor devices, is driving the adoption of dual arm wafer robots. These robots offer enhanced precision, speed, and efficiency, making them indispensable in modern manufacturing environments. As industries continue to evolve and embrace automation, the demand for dual arm wafer robots is expected to rise, contributing to the market's growth. The projected growth rate of 5.6% indicates a steady increase in market size, reflecting the ongoing advancements in robotics technology and the expanding applications of these robots in various industries. The market's expansion is also supported by the continuous innovation in robot design and functionality, enabling manufacturers to meet the evolving needs of the semiconductor industry and other sectors. As a result, the global dual arm wafer robot market is poised for significant growth in the coming years, driven by the increasing demand for automation and the continuous advancements in robotics technology.

| Report Metric | Details |

| Report Name | Dual Arm Wafer Robot Market |

| Accounted market size in year | US$ 714 million |

| Forecasted market size in 2031 | US$ 1040 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Kawasaki Robotics, RORZE Corporation, Brooks Automation, DAIHEN Corporation, Hirata Corporation, Yaskawa, Nidec (Genmark Automation), JEL Corporation, Shibaura Machine, Robostar, Robots and Design (RND), HYULIM Robot, RAONTEC Inc, Cymechs Inc, Tazmo, Rexxam Co Ltd, ULVAC, Kensington Laboratories, EPSON Robots, Hine Automation, Moog Inc, Innovative Robotics, Staubli, isel Germany AG, Sanwa Engineering Corporation, Siasun Robot & Automation, HIWIN TECHNOLOGIES, He-Five LLC., Shanghai HIROKAWA, PHT Inc., Wuxi Xinghui Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |