What is Global LNG Liquefaction Equipment Market?

The Global LNG Liquefaction Equipment Market is a crucial segment within the energy sector, focusing on the technology and machinery used to convert natural gas into liquefied natural gas (LNG). This process involves cooling natural gas to a temperature of approximately -162 degrees Celsius, transforming it into a liquid state, which significantly reduces its volume and makes it easier to store and transport. The market for LNG liquefaction equipment is driven by the increasing demand for cleaner energy sources, as LNG is considered a more environmentally friendly alternative to coal and oil. The equipment used in this process includes heat exchangers, compressors, and LNG pumps, each playing a vital role in ensuring the efficient and safe conversion of natural gas. As global energy needs continue to rise, the demand for LNG and the equipment necessary for its production is expected to grow, making this market an essential component of the global energy landscape. The market is characterized by technological advancements and innovations aimed at improving efficiency and reducing costs, which are critical factors for companies operating in this competitive industry.

Heat Exchanger, Compressor, LNG Pump, Others in the Global LNG Liquefaction Equipment Market:

Heat exchangers, compressors, LNG pumps, and other equipment are integral components of the Global LNG Liquefaction Equipment Market, each serving a specific function in the liquefaction process. Heat exchangers are crucial as they facilitate the transfer of heat between two or more fluids, which is essential in cooling the natural gas to its liquefied state. These devices are designed to maximize heat transfer efficiency while minimizing energy consumption, making them a critical component in the overall efficiency of the LNG production process. Compressors, on the other hand, are used to increase the pressure of the natural gas, which is necessary for the liquefaction process. By compressing the gas, the equipment ensures that it reaches the required pressure levels for efficient cooling and liquefaction. LNG pumps are responsible for moving the liquefied natural gas through the production and storage systems. These pumps must be designed to handle the extremely low temperatures of LNG, ensuring safe and efficient transportation within the facility. Other equipment in the LNG liquefaction process includes valves, control systems, and storage tanks, each playing a vital role in maintaining the integrity and safety of the operation. Valves are used to control the flow of gas and LNG throughout the system, while control systems monitor and regulate the various processes to ensure optimal performance. Storage tanks are designed to safely store the liquefied gas until it is ready for transport. The integration of these components is essential for the successful operation of an LNG facility, and advancements in technology continue to enhance their performance and reliability. As the demand for LNG grows, the development of more efficient and cost-effective equipment is crucial for meeting global energy needs. Companies in this market are continually investing in research and development to improve the design and functionality of their equipment, ensuring they remain competitive in this rapidly evolving industry. The focus on sustainability and reducing environmental impact is also driving innovation, with manufacturers seeking to develop equipment that minimizes emissions and energy consumption. This commitment to innovation and efficiency is vital for the future growth and success of the Global LNG Liquefaction Equipment Market.

Small LNG Plants (Below 0.25 MTPA), Mid-Scale LNG Plants (0.25 to 2.0 MTPA), Large LNG Plants (Above 2.0 MTPA) in the Global LNG Liquefaction Equipment Market:

The usage of Global LNG Liquefaction Equipment Market varies significantly across different scales of LNG plants, including small, mid-scale, and large facilities. Small LNG plants, with a capacity below 0.25 MTPA (Million Tonnes Per Annum), typically serve niche markets or remote locations where traditional energy infrastructure is not feasible. These plants rely on compact and efficient liquefaction equipment to produce LNG for local consumption, often for use in transportation or as a substitute for diesel in power generation. The equipment used in small LNG plants must be cost-effective and easy to maintain, as these facilities often operate in challenging environments with limited access to technical support. Mid-scale LNG plants, with capacities ranging from 0.25 to 2.0 MTPA, serve a broader range of applications, including regional energy supply and industrial use. These plants require more robust and scalable equipment to handle larger volumes of natural gas, while still maintaining efficiency and reliability. The equipment used in mid-scale plants often incorporates advanced technologies to optimize performance and reduce operational costs, making them an attractive option for companies looking to expand their LNG production capabilities. Large LNG plants, with capacities above 2.0 MTPA, are designed to meet the demands of global energy markets, supplying LNG to countries and regions with high energy consumption. These facilities require highly sophisticated and efficient liquefaction equipment to process vast quantities of natural gas, ensuring a steady and reliable supply of LNG to international markets. The equipment used in large LNG plants is typically custom-designed to meet the specific needs of the facility, incorporating the latest advancements in technology to maximize efficiency and minimize environmental impact. The scale of these operations also necessitates a high level of automation and control, with advanced monitoring systems in place to ensure the safe and efficient operation of the plant. As the demand for LNG continues to grow, the development of more efficient and cost-effective equipment for all scales of LNG plants is essential for meeting global energy needs. Companies in the Global LNG Liquefaction Equipment Market are continually investing in research and development to improve the design and functionality of their equipment, ensuring they remain competitive in this rapidly evolving industry. The focus on sustainability and reducing environmental impact is also driving innovation, with manufacturers seeking to develop equipment that minimizes emissions and energy consumption. This commitment to innovation and efficiency is vital for the future growth and success of the Global LNG Liquefaction Equipment Market.

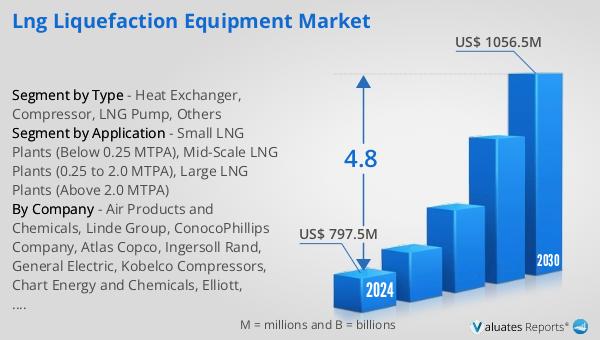

Global LNG Liquefaction Equipment Market Outlook:

In 2024, the global market for LNG Liquefaction Equipment was valued at approximately $832 million. Projections indicate that by 2031, this market is expected to expand to a revised size of around $1,150 million, reflecting a compound annual growth rate (CAGR) of 4.8% over the forecast period. The Americas region is a significant player in this market, holding about 26% of the market share. Furthermore, the top three companies in this sector collectively account for approximately 30% of the market share, highlighting the competitive nature of the industry. This growth is driven by the increasing demand for cleaner energy sources and the need for efficient and cost-effective equipment to support the production of liquefied natural gas. As the global energy landscape continues to evolve, the LNG Liquefaction Equipment Market is poised to play a crucial role in meeting the world's energy needs. The focus on technological advancements and innovation is essential for companies looking to maintain their competitive edge in this dynamic market. By investing in research and development, companies can improve the efficiency and performance of their equipment, ensuring they remain at the forefront of the industry. The commitment to sustainability and reducing environmental impact is also a key driver of growth, with manufacturers seeking to develop equipment that minimizes emissions and energy consumption. This dedication to innovation and efficiency is vital for the continued success and expansion of the Global LNG Liquefaction Equipment Market.

| Report Metric | Details |

| Report Name | LNG Liquefaction Equipment Market |

| Accounted market size in year | US$ 832 million |

| Forecasted market size in 2031 | US$ 1150 million |

| CAGR | 4.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Air Products and Chemicals, Linde Group, ConocoPhillips Company, Atlas Copco, Ingersoll Rand, General Electric, Kobelco Compressors, Chart Energy and Chemicals, Elliott, MITSUI E&S, MCO, IHI Corporation, Mitsubishi Heavy Industries (MHI), NEUMAN & ESSER, Cryostar, Nikkiso, Fives Group, Sichuan Air Separation Equipment (Group), Liaoning CIMC Harbin Cryogenic Gas Liquefaction Equipment, Suzhou Oxygen Plant, Shaanxi Blower (Group), Chengdu Shenleng Liquefaction Plant, Hangzhou Zhongtai Cryogenic Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |