What is Global Double Station Extrusion Blow Molding Machine Market?

The Global Double Station Extrusion Blow Molding Machine Market refers to the industry focused on the production and sale of machines designed for extrusion blow molding processes. These machines are pivotal in manufacturing hollow plastic products by melting plastic and forming it into a parison, which is then inflated into a mold cavity to create the desired shape. The "double station" aspect indicates that these machines have two stations, allowing for simultaneous production, which enhances efficiency and output. This market is driven by the demand for lightweight, durable, and cost-effective plastic products across various industries. The versatility of these machines enables the production of a wide range of products, from simple containers to complex automotive parts. As industries continue to seek sustainable and efficient manufacturing solutions, the demand for advanced extrusion blow molding machines is expected to grow. This market is characterized by technological advancements, increasing automation, and a focus on energy efficiency, which are key factors influencing its development and adoption across different sectors.

Continuous Extrusion Blow Moulding, Intermittent Extrusion Blow Moulding in the Global Double Station Extrusion Blow Molding Machine Market:

Continuous Extrusion Blow Molding and Intermittent Extrusion Blow Molding are two primary processes within the Global Double Station Extrusion Blow Molding Machine Market, each offering distinct advantages and applications. Continuous Extrusion Blow Molding involves the constant extrusion of a parison, which is then captured by the mold and inflated to form the final product. This method is highly efficient for producing large volumes of uniform products, such as bottles and containers, due to its uninterrupted production flow. The continuous nature of this process minimizes downtime and maximizes output, making it ideal for high-demand industries like food and beverage packaging. On the other hand, Intermittent Extrusion Blow Molding, also known as accumulator head blow molding, involves the periodic extrusion of the parison. This process is suitable for producing larger and more complex products that require precise control over wall thickness and material distribution. The intermittent nature allows for the accumulation of a larger amount of material before extrusion, enabling the production of items with varying thicknesses and intricate designs. This method is often used in the automotive and industrial sectors, where the demand for robust and customized components is high. Both processes benefit from the double station configuration, which enhances productivity by allowing simultaneous operations. The choice between continuous and intermittent extrusion blow molding depends on factors such as product design, material requirements, and production volume. Continuous extrusion is favored for its speed and efficiency in producing simple, high-volume items, while intermittent extrusion offers greater flexibility and control for complex, low-volume products. As the market evolves, advancements in technology and automation are expected to further optimize these processes, enhancing their capabilities and expanding their applications across various industries.

Food and Beverage, Pharmaceutical, Cosmetic and Personal Care, Others in the Global Double Station Extrusion Blow Molding Machine Market:

The Global Double Station Extrusion Blow Molding Machine Market finds extensive usage across several key sectors, including Food and Beverage, Pharmaceutical, Cosmetic and Personal Care, and others. In the Food and Beverage industry, these machines are crucial for producing a wide range of packaging solutions, such as bottles, containers, and jars. The ability to produce lightweight, durable, and cost-effective packaging is essential for maintaining product quality and extending shelf life. The demand for sustainable and recyclable packaging solutions is also driving innovation in this sector, with extrusion blow molding machines playing a pivotal role in meeting these requirements. In the Pharmaceutical industry, precision and hygiene are paramount. Extrusion blow molding machines are used to manufacture containers and packaging that meet stringent regulatory standards. The ability to produce sterile and tamper-proof packaging is critical for ensuring the safety and efficacy of pharmaceutical products. The Cosmetic and Personal Care industry relies on these machines for creating aesthetically pleasing and functional packaging solutions. The versatility of extrusion blow molding allows for the production of uniquely shaped bottles and containers that enhance brand identity and consumer appeal. Additionally, the ability to incorporate features such as handles and spouts adds convenience for end-users. Beyond these sectors, the Global Double Station Extrusion Blow Molding Machine Market serves various other industries, including automotive, industrial, and household products. The demand for customized and durable components in these sectors drives the adoption of advanced extrusion blow molding technologies. As industries continue to prioritize sustainability and efficiency, the role of these machines in producing eco-friendly and innovative solutions is expected to grow, further expanding their applications and market reach.

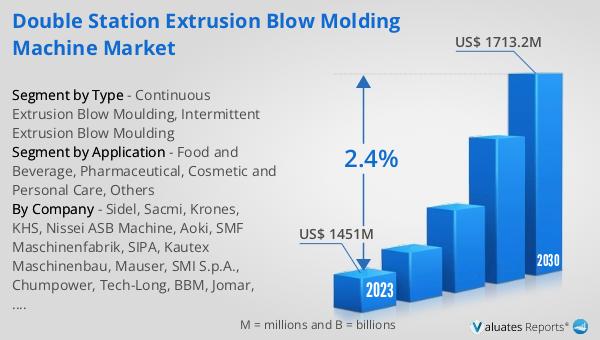

Global Double Station Extrusion Blow Molding Machine Market Outlook:

The global market for Double Station Extrusion Blow Molding Machines was valued at $1,518 million in 2024. It is anticipated to grow to a revised size of $1,788 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.4% during the forecast period. This growth trajectory underscores the increasing demand for efficient and versatile manufacturing solutions across various industries. The steady growth rate indicates a stable market environment, driven by technological advancements and the rising need for sustainable and cost-effective production methods. The market's expansion is supported by the continuous development of innovative features and automation capabilities in extrusion blow molding machines, enhancing their efficiency and output. As industries seek to optimize production processes and reduce environmental impact, the adoption of advanced blow molding technologies is expected to rise. The projected growth also highlights the importance of these machines in meeting the evolving needs of sectors such as food and beverage, pharmaceuticals, cosmetics, and personal care. With a focus on improving product quality and reducing production costs, the Global Double Station Extrusion Blow Molding Machine Market is poised for sustained growth, offering significant opportunities for manufacturers and stakeholders in the coming years.

| Report Metric | Details |

| Report Name | Double Station Extrusion Blow Molding Machine Market |

| Accounted market size in year | US$ 1518 million |

| Forecasted market size in 2031 | US$ 1788 million |

| CAGR | 2.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sidel, Sacmi, Krones, KHS, Nissei ASB Machine, Aoki, SMF Maschinenfabrik, SIPA, Kautex Maschinenbau, Mauser, SMI S.p.A., Chumpower, Tech-Long, BBM, Jomar, Parker, ZQ Machinery, Bekum, Plastiblow |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |