What is Global Zero Cogging Direct Drive Motors Market?

The Global Zero Cogging Direct Drive Motors Market refers to a specialized segment within the broader motor industry that focuses on motors designed to eliminate cogging torque. Cogging torque is an undesirable effect in motors that causes jerky movements, which can be detrimental to precision applications. Zero cogging direct drive motors are engineered to provide smooth, continuous motion without the interruptions caused by cogging. These motors are particularly valuable in applications requiring high precision and reliability, such as medical devices, aerospace, defense, and industrial manufacturing. The market for these motors is growing as industries increasingly demand higher performance and precision in their operations. The elimination of cogging torque not only improves the efficiency and accuracy of the motors but also extends their lifespan, making them a cost-effective solution in the long run. As technology advances, the adoption of zero cogging direct drive motors is expected to rise, driven by the need for enhanced performance in various high-stakes applications.

Linear Slotless Motor, Rotary Slotless Motor in the Global Zero Cogging Direct Drive Motors Market:

Linear slotless motors and rotary slotless motors are two key types of motors within the Global Zero Cogging Direct Drive Motors Market. Linear slotless motors are designed to provide linear motion without the cogging effects that can disrupt smooth operation. These motors are often used in applications where precise linear movement is critical, such as in medical imaging equipment, semiconductor manufacturing, and automated assembly lines. The absence of slots in the motor's design eliminates the magnetic attraction between the stator and the rotor, resulting in a smoother and more accurate motion. This makes linear slotless motors ideal for tasks that require high precision and minimal vibration. On the other hand, rotary slotless motors are designed to provide rotational motion without the cogging effects. These motors are commonly used in applications such as robotics, aerospace, and defense systems, where precise rotational movement is essential. The slotless design of these motors eliminates the magnetic cogging torque, allowing for smoother and more accurate rotational motion. This is particularly important in applications where even the slightest interruption in motion can lead to significant errors or failures. Both linear and rotary slotless motors offer significant advantages over traditional motors, including improved efficiency, reduced maintenance, and longer lifespan. As industries continue to demand higher precision and reliability in their operations, the adoption of these advanced motor technologies is expected to increase. The Global Zero Cogging Direct Drive Motors Market is poised for growth as more industries recognize the benefits of these innovative motor solutions.

Medical Industry, Aerospace and Defense, Industrial Manufacturing, Others in the Global Zero Cogging Direct Drive Motors Market:

The usage of Global Zero Cogging Direct Drive Motors Market in various industries highlights the versatility and importance of these advanced motor technologies. In the medical industry, zero cogging direct drive motors are used in a wide range of applications, including surgical robots, diagnostic imaging equipment, and patient care devices. The smooth and precise motion provided by these motors is crucial for ensuring the accuracy and reliability of medical procedures and equipment. For example, in surgical robots, the elimination of cogging torque allows for more precise and controlled movements, which can lead to better surgical outcomes and reduced recovery times for patients. In the aerospace and defense sectors, zero cogging direct drive motors are used in applications such as satellite positioning systems, unmanned aerial vehicles (UAVs), and missile guidance systems. The high precision and reliability of these motors are essential for the successful operation of these critical systems. The elimination of cogging torque ensures smooth and accurate movements, which can be the difference between mission success and failure. In industrial manufacturing, zero cogging direct drive motors are used in a variety of applications, including automated assembly lines, CNC machines, and robotic arms. The smooth and precise motion provided by these motors improves the efficiency and accuracy of manufacturing processes, leading to higher quality products and reduced production costs. Additionally, the reduced maintenance requirements and longer lifespan of these motors make them a cost-effective solution for manufacturers. Other industries that benefit from zero cogging direct drive motors include the automotive, semiconductor, and renewable energy sectors. In the automotive industry, these motors are used in electric vehicles (EVs) to provide smooth and efficient propulsion. In the semiconductor industry, they are used in precision manufacturing equipment to ensure the accuracy and reliability of semiconductor components. In the renewable energy sector, zero cogging direct drive motors are used in wind turbines to provide smooth and efficient power generation. Overall, the versatility and benefits of zero cogging direct drive motors make them an essential component in a wide range of industries.

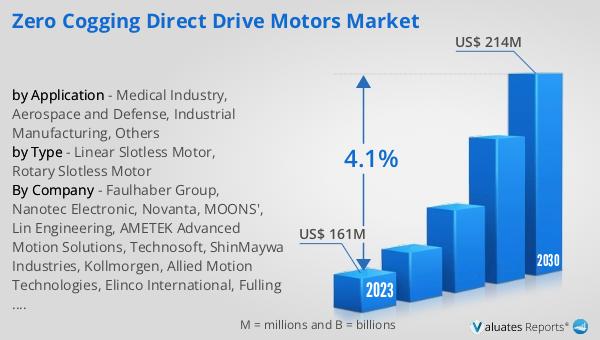

Global Zero Cogging Direct Drive Motors Market Outlook:

The global Zero Cogging Direct Drive Motors market was valued at US$ 161 million in 2023 and is anticipated to reach US$ 214 million by 2030, witnessing a CAGR of 4.1% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for high-precision and reliable motor solutions across various industries. The elimination of cogging torque in these motors enhances their performance, making them a preferred choice for applications requiring smooth and continuous motion. As industries such as medical, aerospace, defense, and industrial manufacturing continue to evolve and demand higher performance standards, the adoption of zero cogging direct drive motors is expected to rise. The market's growth is also supported by advancements in motor technology, which are making these motors more efficient and cost-effective. The projected growth in the market value reflects the increasing recognition of the benefits of zero cogging direct drive motors and their expanding applications across different sectors. As a result, manufacturers and suppliers in this market are likely to see significant opportunities for growth and innovation in the coming years.

| Report Metric | Details |

| Report Name | Zero Cogging Direct Drive Motors Market |

| Accounted market size in 2023 | US$ 161 million |

| Forecasted market size in 2030 | US$ 214 million |

| CAGR | 4.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Faulhaber Group, Nanotec Electronic, Novanta, MOONS', Lin Engineering, AMETEK Advanced Motion Solutions, Technosoft, ShinMaywa Industries, Kollmorgen, Allied Motion Technologies, Elinco International, Fulling Motor, DINGS' |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |