What is Global Sustainable Film-Based Release Liner Market?

The Global Sustainable Film-Based Release Liner Market is a specialized segment within the broader packaging and labeling industry. Release liners are essential components used to protect adhesive surfaces until they are ready for application. These liners are typically made from paper or film and are coated with a release agent to prevent the adhesive from sticking prematurely. The sustainable film-based release liner market focuses on environmentally friendly options, utilizing materials that are recyclable, biodegradable, or made from renewable resources. This market is driven by increasing environmental awareness and stringent regulations aimed at reducing plastic waste. Companies in this sector are innovating to create liners that not only meet performance standards but also minimize environmental impact. The demand for sustainable solutions is growing across various industries, including medical, electronics, and printing, making this market a crucial area for future development.

Silicone Based, Non-Silicone Based in the Global Sustainable Film-Based Release Liner Market:

Silicone-based and non-silicone-based release liners are two primary categories within the Global Sustainable Film-Based Release Liner Market. Silicone-based release liners are widely used due to their excellent release properties, which make them ideal for applications requiring a smooth and consistent release. These liners are often used in high-performance applications such as medical devices, electronics, and automotive components. Silicone coatings provide a reliable barrier that prevents adhesives from sticking prematurely, ensuring that the adhesive remains effective until it is applied. However, the production and disposal of silicone-based liners can pose environmental challenges, prompting the industry to explore more sustainable alternatives. Non-silicone-based release liners, on the other hand, are gaining traction as eco-friendly alternatives. These liners can be made from various materials, including polyethylene, polypropylene, and other biodegradable or recyclable films. Non-silicone coatings, such as those based on fluoropolymers or other synthetic materials, offer similar release properties without the environmental drawbacks associated with silicone. These liners are particularly appealing in applications where sustainability is a key concern, such as food packaging, consumer goods, and certain medical applications. The shift towards non-silicone-based liners is driven by several factors, including regulatory pressures, consumer demand for greener products, and advancements in material science. Companies are investing in research and development to create non-silicone coatings that match or exceed the performance of traditional silicone-based liners. This includes improving the durability, heat resistance, and release characteristics of these alternatives to ensure they meet the rigorous demands of various industries. In addition to material innovations, the sustainable film-based release liner market is also focusing on improving the overall lifecycle of these products. This includes developing liners that are easier to recycle, reducing the carbon footprint of production processes, and exploring the use of renewable resources. For example, some companies are experimenting with bio-based polymers derived from plants or other renewable sources to create release liners that are both effective and environmentally friendly. The adoption of sustainable release liners is not without its challenges. One of the primary hurdles is the cost associated with developing and producing these advanced materials. While the long-term benefits of sustainability are clear, the initial investment can be significant. Additionally, there is a need for industry-wide standards and certifications to ensure that sustainable claims are credible and verifiable. This will help build trust among consumers and encourage wider adoption of eco-friendly release liners. Despite these challenges, the outlook for the Global Sustainable Film-Based Release Liner Market is positive. As more industries recognize the importance of sustainability, the demand for innovative, eco-friendly solutions will continue to grow. Companies that can successfully navigate the complexities of this market and deliver high-performance, sustainable products will be well-positioned for success. The ongoing advancements in material science, coupled with increasing regulatory and consumer pressures, will drive the evolution of this market in the coming years.

Medical Industry, Printing Industry, Eletronics Industry, Others in the Global Sustainable Film-Based Release Liner Market:

The Global Sustainable Film-Based Release Liner Market finds extensive usage across various industries, including the medical, printing, electronics, and other sectors. In the medical industry, these liners are crucial for applications such as wound care products, medical tapes, and transdermal drug delivery systems. The liners protect the adhesive components of these products, ensuring they remain sterile and effective until use. Sustainable film-based release liners in the medical field are particularly important due to the stringent regulatory requirements and the need for biocompatibility. The shift towards eco-friendly materials in this sector is driven by the dual goals of maintaining high performance and reducing environmental impact. In the printing industry, sustainable film-based release liners are used in the production of labels, decals, and graphic films. These liners provide a stable backing that allows for precise printing and cutting, ensuring that the final product adheres smoothly to various surfaces. The move towards sustainable liners in printing is influenced by the growing demand for environmentally responsible packaging and labeling solutions. Printers and converters are increasingly seeking materials that offer both high performance and reduced environmental footprint, making sustainable film-based release liners an attractive option. The electronics industry also relies heavily on release liners for various applications, including the production of electronic components, protective films, and adhesive tapes used in device assembly. In this sector, the performance requirements for release liners are particularly stringent, as they must withstand high temperatures and provide consistent release properties. Sustainable film-based release liners in electronics are gaining traction as manufacturers look to reduce the environmental impact of their products. This includes using recyclable or biodegradable materials and minimizing waste during the production process. Beyond these primary industries, sustainable film-based release liners are also used in a variety of other applications. This includes the automotive industry, where they are used in the production of adhesive components for vehicle assembly and maintenance. The construction industry also utilizes these liners for applications such as roofing materials and insulation products. In consumer goods, sustainable release liners are used in products ranging from hygiene items to packaging materials. The versatility of these liners makes them an essential component in many different sectors, all of which are increasingly prioritizing sustainability. The adoption of sustainable film-based release liners across these industries is driven by several key factors. Regulatory pressures are a significant driver, as governments and industry bodies implement stricter environmental standards. Consumer demand for greener products is also a major influence, with more individuals and businesses seeking out eco-friendly options. Additionally, advancements in material science are making it possible to develop sustainable liners that do not compromise on performance, making them a viable alternative to traditional materials. In conclusion, the Global Sustainable Film-Based Release Liner Market plays a vital role in a wide range of industries, from medical and printing to electronics and beyond. The shift towards sustainable materials in this market is driven by a combination of regulatory pressures, consumer demand, and technological advancements. As industries continue to prioritize sustainability, the demand for innovative, eco-friendly release liners will only grow. Companies that can deliver high-performance, sustainable solutions will be well-positioned to succeed in this evolving market.

Global Sustainable Film-Based Release Liner Market Outlook:

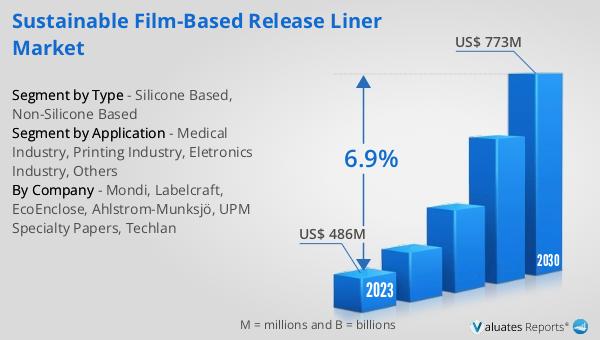

The global Sustainable Film-Based Release Liner market was valued at US$ 486 million in 2023 and is anticipated to reach US$ 773 million by 2030, witnessing a CAGR of 6.9% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of sustainable film-based release liners, driven by increasing environmental awareness and regulatory pressures. The market's expansion reflects the growing demand for eco-friendly alternatives in various industries, including medical, electronics, and printing. Companies operating in this space are focusing on developing innovative materials that offer both high performance and reduced environmental impact. The projected growth underscores the importance of sustainability in the packaging and labeling industry, as businesses and consumers alike seek out greener solutions. As the market continues to evolve, the emphasis on sustainability will drive further advancements in material science and production processes, ensuring that sustainable film-based release liners remain a critical component in a wide range of applications.

| Report Metric | Details |

| Report Name | Sustainable Film-Based Release Liner Market |

| Accounted market size in 2023 | US$ 486 million |

| Forecasted market size in 2030 | US$ 773 million |

| CAGR | 6.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mondi, Labelcraft, EcoEnclose, Ahlstrom-Munksjö, UPM Specialty Papers, Techlan |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |