What is Global Rotary Steam Tube Dryer Market?

The Global Rotary Steam Tube Dryer Market is a specialized segment within the industrial drying equipment industry. Rotary steam tube dryers are used to dry various materials by utilizing steam as the heating medium. These dryers consist of a rotating drum with steam tubes running through it. The steam heats the tubes, which in turn heat the material inside the drum, causing moisture to evaporate. This method is highly efficient and is used in various industries such as food processing, chemicals, and agriculture. The global market for these dryers is driven by the need for efficient drying solutions that can handle large volumes of material while maintaining product quality. The market is characterized by technological advancements, increasing demand for energy-efficient drying solutions, and the need for equipment that can handle a wide range of materials. The market is also influenced by factors such as regulatory requirements, environmental concerns, and the need for cost-effective drying solutions. Overall, the Global Rotary Steam Tube Dryer Market is expected to grow steadily, driven by the increasing demand for efficient and reliable drying solutions across various industries.

Direct Rotary Steam Tube Dryer, Indirect Rotary Steam Tube Dryer in the Global Rotary Steam Tube Dryer Market:

Direct Rotary Steam Tube Dryers and Indirect Rotary Steam Tube Dryers are two main types of dryers used in the Global Rotary Steam Tube Dryer Market. Direct Rotary Steam Tube Dryers involve direct contact between the steam tubes and the material being dried. In this type of dryer, the steam tubes are placed inside the rotating drum, and the material is directly exposed to the heated tubes. This method is highly efficient and is suitable for drying materials that can withstand direct contact with high temperatures. Direct Rotary Steam Tube Dryers are commonly used in industries such as food processing, where the material needs to be dried quickly and efficiently. On the other hand, Indirect Rotary Steam Tube Dryers involve indirect contact between the steam tubes and the material being dried. In this type of dryer, the steam tubes are placed outside the rotating drum, and the heat is transferred to the material through the drum walls. This method is suitable for drying materials that are sensitive to high temperatures or that need to be dried in a controlled environment. Indirect Rotary Steam Tube Dryers are commonly used in industries such as chemicals and pharmaceuticals, where the material needs to be dried gently and uniformly. Both types of dryers have their advantages and disadvantages, and the choice between them depends on the specific requirements of the drying process. Direct Rotary Steam Tube Dryers are generally more efficient and have a higher drying capacity, but they may not be suitable for all types of materials. Indirect Rotary Steam Tube Dryers, on the other hand, offer more control over the drying process and are suitable for a wider range of materials, but they may be less efficient and have a lower drying capacity. Overall, both types of dryers play a crucial role in the Global Rotary Steam Tube Dryer Market, providing efficient and reliable drying solutions for various industries.

Food, Chemical, Agriculture, Others in the Global Rotary Steam Tube Dryer Market:

The Global Rotary Steam Tube Dryer Market finds extensive usage in various industries, including food, chemicals, agriculture, and others. In the food industry, rotary steam tube dryers are used to dry a wide range of food products, including grains, fruits, vegetables, and meat. The efficient drying process helps in preserving the nutritional value and extending the shelf life of food products. In the chemical industry, these dryers are used to dry various chemical compounds and intermediates. The controlled drying process ensures that the chemical properties of the materials are maintained, which is crucial for the quality and performance of the final products. In the agriculture industry, rotary steam tube dryers are used to dry agricultural products such as seeds, grains, and animal feed. The efficient drying process helps in reducing the moisture content of the products, which is essential for preventing spoilage and ensuring long-term storage. In addition to these industries, rotary steam tube dryers are also used in other industries such as pharmaceuticals, mining, and waste management. In the pharmaceutical industry, these dryers are used to dry active pharmaceutical ingredients (APIs) and other pharmaceutical products. The controlled drying process ensures that the quality and efficacy of the pharmaceutical products are maintained. In the mining industry, rotary steam tube dryers are used to dry minerals and ores, which is essential for the extraction and processing of valuable metals. In the waste management industry, these dryers are used to dry waste materials, which helps in reducing the volume and weight of the waste, making it easier to handle and dispose of. Overall, the Global Rotary Steam Tube Dryer Market plays a crucial role in various industries, providing efficient and reliable drying solutions that help in improving the quality and performance of the final products.

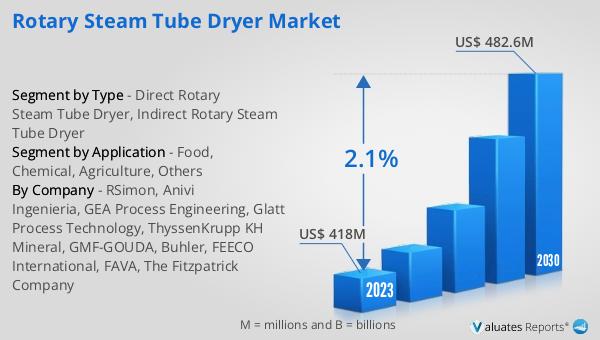

Global Rotary Steam Tube Dryer Market Outlook:

The global Rotary Steam Tube Dryer market was valued at US$ 418 million in 2023 and is anticipated to reach US$ 482.6 million by 2030, witnessing a CAGR of 2.1% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by the increasing demand for efficient and reliable drying solutions across various industries. The market is expected to benefit from technological advancements, increasing demand for energy-efficient drying solutions, and the need for equipment that can handle a wide range of materials. The market is also influenced by factors such as regulatory requirements, environmental concerns, and the need for cost-effective drying solutions. The steady growth of the market is a positive indicator for manufacturers and suppliers of rotary steam tube dryers, as it presents opportunities for expansion and innovation. The market outlook also highlights the importance of continuous research and development to improve the efficiency and performance of rotary steam tube dryers, which will be crucial for maintaining a competitive edge in the market. Overall, the global Rotary Steam Tube Dryer market is expected to witness steady growth, driven by the increasing demand for efficient and reliable drying solutions across various industries.

| Report Metric | Details |

| Report Name | Rotary Steam Tube Dryer Market |

| Accounted market size in 2023 | US$ 418 million |

| Forecasted market size in 2030 | US$ 482.6 million |

| CAGR | 2.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | RSimon, Anivi Ingenieria, GEA Process Engineering, Glatt Process Technology, ThyssenKrupp KH Mineral, GMF-GOUDA, Buhler, FEECO International, FAVA, The Fitzpatrick Company |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |