What is Global PEM Pure Water Electrolysis Hydrogen Production Equipment Market?

The Global PEM Pure Water Electrolysis Hydrogen Production Equipment Market refers to the industry focused on the production of hydrogen through the process of Proton Exchange Membrane (PEM) electrolysis using pure water. This technology is gaining traction due to its ability to produce high-purity hydrogen, which is essential for various applications such as fuel cells, industrial processes, and energy storage. PEM electrolysis involves the use of a solid polymer electrolyte that conducts protons, separates the product gases, and acts as an insulator for electrons. The market for this equipment is expanding as the demand for clean and sustainable energy sources increases globally. The equipment is designed to be efficient, reliable, and scalable, making it suitable for both small-scale and large-scale hydrogen production. The growth of this market is driven by the rising awareness of environmental issues, government policies promoting clean energy, and advancements in technology that make PEM electrolysis more cost-effective and efficient.

Barrier Electrolyzer, No Barrier Electrolyzer in the Global PEM Pure Water Electrolysis Hydrogen Production Equipment Market:

In the Global PEM Pure Water Electrolysis Hydrogen Production Equipment Market, there are two main types of electrolyzers: Barrier Electrolyzers and No Barrier Electrolyzers. Barrier Electrolyzers are designed with a membrane that separates the anode and cathode compartments, preventing the mixing of hydrogen and oxygen gases produced during electrolysis. This separation is crucial for ensuring the purity of the hydrogen gas and enhancing the safety of the process. The membrane used in Barrier Electrolyzers is typically made of a proton-conducting polymer, which allows protons to pass through while blocking electrons and gases. This design helps in achieving high efficiency and purity levels, making Barrier Electrolyzers suitable for applications where high-purity hydrogen is required, such as in fuel cells and certain industrial processes. On the other hand, No Barrier Electrolyzers do not have a membrane separating the anode and cathode compartments. Instead, they rely on other methods to prevent the mixing of hydrogen and oxygen gases. These electrolyzers are generally simpler in design and can be more cost-effective compared to Barrier Electrolyzers. However, they may not achieve the same level of hydrogen purity and efficiency. No Barrier Electrolyzers are often used in applications where the purity of hydrogen is not as critical, or where the cost of the equipment is a significant consideration. They can be suitable for large-scale hydrogen production where the focus is on volume rather than purity. Both types of electrolyzers have their own advantages and disadvantages, and the choice between them depends on the specific requirements of the application. Barrier Electrolyzers are preferred in scenarios where high-purity hydrogen is essential, and safety is a major concern. They are commonly used in fuel cell applications, where the purity of hydrogen directly impacts the performance and longevity of the fuel cells. The high efficiency of Barrier Electrolyzers also makes them suitable for applications where energy efficiency is a priority. No Barrier Electrolyzers, while not as efficient or pure as their barrier counterparts, offer a more economical solution for hydrogen production. They are often used in industrial applications where the hydrogen produced is used as a feedstock for chemical processes, and the purity requirements are not as stringent. The simpler design of No Barrier Electrolyzers also makes them easier to maintain and operate, which can be an important consideration in large-scale industrial settings. In summary, the Global PEM Pure Water Electrolysis Hydrogen Production Equipment Market includes both Barrier and No Barrier Electrolyzers, each with its own set of characteristics and applications. Barrier Electrolyzers are known for their high efficiency and purity, making them suitable for applications where these factors are critical. No Barrier Electrolyzers, on the other hand, offer a more cost-effective solution for hydrogen production, making them suitable for applications where cost is a major consideration, and purity requirements are less stringent. The choice between these two types of electrolyzers depends on the specific needs of the application, including factors such as purity requirements, cost constraints, and operational considerations.

Generate Electricity, Hydrogen Refueling, Industry, Others in the Global PEM Pure Water Electrolysis Hydrogen Production Equipment Market:

The Global PEM Pure Water Electrolysis Hydrogen Production Equipment Market finds its usage in various areas, including generating electricity, hydrogen refueling, industrial applications, and other miscellaneous uses. In the context of generating electricity, PEM electrolysis plays a crucial role in the production of hydrogen, which can be used as a clean fuel in fuel cells. Fuel cells convert hydrogen into electricity through an electrochemical process, producing only water and heat as by-products. This makes them an environmentally friendly alternative to traditional fossil fuel-based power generation methods. The high efficiency and purity of hydrogen produced through PEM electrolysis make it an ideal choice for fuel cell applications, which are increasingly being used in stationary power generation, backup power systems, and even in portable power devices. Hydrogen refueling is another significant application of the Global PEM Pure Water Electrolysis Hydrogen Production Equipment Market. Hydrogen refueling stations are essential for the adoption of hydrogen fuel cell vehicles (FCVs), which are seen as a promising solution for reducing greenhouse gas emissions in the transportation sector. PEM electrolysis provides a reliable and efficient method for producing the high-purity hydrogen required for FCVs. The ability to produce hydrogen on-site at refueling stations using PEM electrolysis can help overcome some of the challenges associated with hydrogen distribution and storage. This can facilitate the development of a robust hydrogen refueling infrastructure, which is critical for the widespread adoption of hydrogen-powered vehicles. In industrial applications, the hydrogen produced through PEM electrolysis is used as a feedstock for various chemical processes. Industries such as petroleum refining, ammonia production, and methanol synthesis require large quantities of hydrogen. The high purity of hydrogen produced through PEM electrolysis makes it suitable for these applications, where impurities can negatively impact the efficiency and quality of the chemical processes. Additionally, the use of PEM electrolysis for hydrogen production in industrial settings can help reduce the carbon footprint of these industries, as it provides a cleaner alternative to traditional hydrogen production methods, such as steam methane reforming. Apart from generating electricity, hydrogen refueling, and industrial applications, the Global PEM Pure Water Electrolysis Hydrogen Production Equipment Market also finds usage in other areas. For instance, hydrogen produced through PEM electrolysis can be used in the food industry for hydrogenation processes, which are used to convert unsaturated fats and oils into saturated fats. It can also be used in the electronics industry for applications such as semiconductor manufacturing, where high-purity hydrogen is required for certain processes. Additionally, hydrogen can be used as a reducing agent in metallurgical processes, helping to reduce metal ores to their pure metal forms. In summary, the Global PEM Pure Water Electrolysis Hydrogen Production Equipment Market has a wide range of applications, including generating electricity, hydrogen refueling, industrial processes, and other miscellaneous uses. The high efficiency and purity of hydrogen produced through PEM electrolysis make it suitable for fuel cell applications, which are increasingly being used for clean power generation. Hydrogen refueling stations rely on PEM electrolysis to produce the high-purity hydrogen required for fuel cell vehicles, facilitating the development of a hydrogen refueling infrastructure. In industrial settings, PEM electrolysis provides a cleaner alternative for hydrogen production, reducing the carbon footprint of various chemical processes. Additionally, the hydrogen produced through PEM electrolysis finds usage in other areas such as the food, electronics, and metallurgical industries.

Global PEM Pure Water Electrolysis Hydrogen Production Equipment Market Outlook:

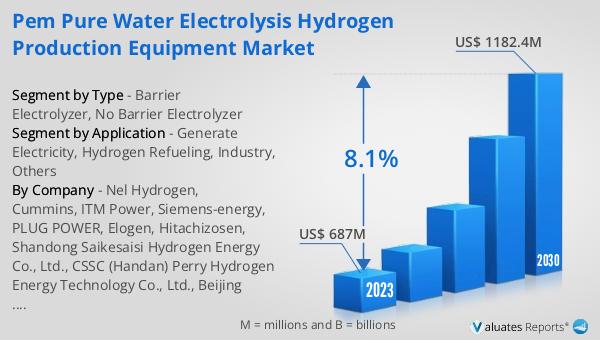

The global market for PEM Pure Water Electrolysis Hydrogen Production Equipment was valued at approximately $687 million in 2023. Projections indicate that this market is expected to grow significantly, reaching around $1,182.4 million by the year 2030. This growth is anticipated to occur at a compound annual growth rate (CAGR) of 8.1% during the forecast period from 2024 to 2030. This upward trend reflects the increasing demand for clean and sustainable energy solutions, driven by environmental concerns and supportive government policies. The advancements in PEM electrolysis technology, which make hydrogen production more efficient and cost-effective, also contribute to this market growth. As industries and governments worldwide continue to prioritize the transition to cleaner energy sources, the market for PEM Pure Water Electrolysis Hydrogen Production Equipment is poised for substantial expansion.

| Report Metric | Details |

| Report Name | PEM Pure Water Electrolysis Hydrogen Production Equipment Market |

| Accounted market size in 2023 | US$ 687 million |

| Forecasted market size in 2030 | US$ 1182.4 million |

| CAGR | 8.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nel Hydrogen, Cummins, ITM Power, Siemens-energy, PLUG POWER, Elogen, Hitachizosen, Shandong Saikesaisi Hydrogen Energy Co., Ltd., CSSC (Handan) Perry Hydrogen Energy Technology Co., Ltd., Beijing SinoHy Energy Co., Ltd., Jiangsu Guofu Hydrogen Energy Technology Equipment Co., Ltd., Hydrogen Era Technology Co., Ltd., Lvhydrogen |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |