What is Global Non-Intrusive Flow Measurement Market?

The Global Non-Intrusive Flow Measurement Market refers to the industry focused on technologies that measure the flow of liquids and gases without physically penetrating the pipe or channel through which the substance flows. This market includes a variety of devices and systems that utilize ultrasonic, electromagnetic, and other advanced technologies to gauge flow rates accurately. These non-intrusive methods are particularly advantageous because they do not disrupt the flow or require the system to be shut down for installation or maintenance. This makes them highly suitable for applications where maintaining the integrity of the pipeline is crucial, such as in chemical processing, oil and gas, water treatment, and other industrial sectors. The market is driven by the need for efficient, reliable, and low-maintenance flow measurement solutions that can operate under a wide range of conditions and in various environments. As industries continue to seek ways to optimize their operations and reduce downtime, the demand for non-intrusive flow measurement technologies is expected to grow.

Gas Flow Meters, Liquid Flow Meters in the Global Non-Intrusive Flow Measurement Market:

Gas flow meters and liquid flow meters are essential components of the Global Non-Intrusive Flow Measurement Market. Gas flow meters are designed to measure the flow rate of gases in various industrial applications. These meters often use ultrasonic or thermal mass flow technologies to provide accurate and reliable measurements without disrupting the gas flow. Ultrasonic gas flow meters work by sending ultrasonic waves through the gas and measuring the time it takes for the waves to travel from one transducer to another. This time difference is used to calculate the flow rate. Thermal mass flow meters, on the other hand, measure the flow rate based on the heat transfer from a heated element to the gas flow. These meters are widely used in industries such as oil and gas, chemical processing, and power generation, where precise gas flow measurement is critical for process control and safety. Liquid flow meters, on the other hand, are designed to measure the flow rate of liquids in various industrial processes. Non-intrusive liquid flow meters typically use ultrasonic or electromagnetic technologies. Ultrasonic liquid flow meters operate on the same principle as their gas counterparts, using ultrasonic waves to measure the flow rate. These meters are highly accurate and can measure the flow of a wide range of liquids, including water, chemicals, and petroleum products. Electromagnetic flow meters, also known as magmeters, measure the flow rate based on the principle of electromagnetic induction. When a conductive liquid flows through a magnetic field, it generates a voltage proportional to the flow rate. This voltage is then measured and converted into a flow rate reading. Magmeters are particularly useful for measuring the flow of conductive liquids, such as water and wastewater, and are widely used in industries such as water treatment, chemical processing, and food and beverage production. Both gas and liquid flow meters offer several advantages over traditional intrusive flow measurement methods. They do not require the pipe to be cut or drilled, which eliminates the risk of leaks and contamination. This makes them ideal for applications where maintaining the integrity of the pipeline is crucial. Additionally, non-intrusive flow meters are easier to install and maintain, as they do not require the system to be shut down for installation or maintenance. This reduces downtime and operational costs, making them a cost-effective solution for many industries. Furthermore, these meters can operate under a wide range of conditions, including high temperatures, high pressures, and corrosive environments, making them suitable for use in harsh industrial settings. In summary, gas flow meters and liquid flow meters are vital components of the Global Non-Intrusive Flow Measurement Market. They provide accurate and reliable flow measurements without disrupting the flow or compromising the integrity of the pipeline. These meters are widely used in various industries, including oil and gas, chemical processing, water treatment, and food and beverage production, where precise flow measurement is essential for process control and safety. As industries continue to seek ways to optimize their operations and reduce downtime, the demand for non-intrusive flow measurement technologies is expected to grow.

Chemical and Petrochemical, Oil and Gas, Food and Beverage, Water and Wastewater, Power and Energy, Other in the Global Non-Intrusive Flow Measurement Market:

The Global Non-Intrusive Flow Measurement Market finds extensive usage across various industries, including chemical and petrochemical, oil and gas, food and beverage, water and wastewater, power and energy, and others. In the chemical and petrochemical industry, non-intrusive flow measurement technologies are crucial for monitoring the flow of various chemicals and ensuring precise control of chemical reactions. These technologies help maintain the integrity of the pipelines, prevent leaks, and reduce the risk of contamination. They are also used to measure the flow of corrosive and hazardous chemicals, where traditional intrusive methods may not be suitable. In the oil and gas industry, non-intrusive flow measurement technologies are used to monitor the flow of crude oil, natural gas, and refined products. These technologies provide accurate and reliable measurements, which are essential for process control, custody transfer, and leak detection. Non-intrusive flow meters are particularly useful in offshore and remote locations, where maintenance and downtime can be costly and challenging. They help ensure the safe and efficient operation of pipelines and reduce the risk of environmental incidents. The food and beverage industry also benefits from non-intrusive flow measurement technologies. These technologies are used to measure the flow of various liquids, including water, milk, juices, and other beverages. Non-intrusive flow meters help maintain the hygiene and integrity of the production process, as they do not come into contact with the liquid being measured. This reduces the risk of contamination and ensures the quality and safety of the final product. Additionally, these meters are used to monitor the flow of cleaning agents and other chemicals used in the production process, ensuring precise dosing and reducing waste. In the water and wastewater industry, non-intrusive flow measurement technologies are used to monitor the flow of water and wastewater in treatment plants and distribution networks. These technologies provide accurate and reliable measurements, which are essential for process control, leak detection, and billing purposes. Non-intrusive flow meters are particularly useful in measuring the flow of water in large pipelines and remote locations, where traditional intrusive methods may not be feasible. They help ensure the efficient operation of water and wastewater treatment plants and reduce the risk of leaks and water loss. The power and energy industry also relies on non-intrusive flow measurement technologies to monitor the flow of various fluids, including water, steam, and natural gas. These technologies are used in power plants, refineries, and other energy facilities to ensure precise control of the flow and optimize the efficiency of the processes. Non-intrusive flow meters help reduce downtime and maintenance costs, as they do not require the system to be shut down for installation or maintenance. They also provide accurate and reliable measurements, which are essential for process control and safety. Other industries that use non-intrusive flow measurement technologies include pharmaceuticals, pulp and paper, and mining. In the pharmaceutical industry, these technologies are used to measure the flow of various liquids and gases in the production of drugs and other medical products. They help ensure the precise control of the production process and maintain the integrity of the pipelines. In the pulp and paper industry, non-intrusive flow meters are used to measure the flow of water, chemicals, and other fluids used in the production process. They help optimize the efficiency of the processes and reduce waste. In the mining industry, non-intrusive flow measurement technologies are used to monitor the flow of water and other fluids used in the extraction and processing of minerals. They help ensure the efficient operation of the processes and reduce the risk of environmental incidents.

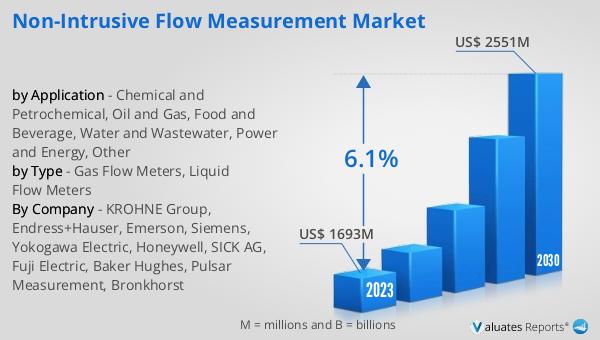

Global Non-Intrusive Flow Measurement Market Outlook:

The global Non-Intrusive Flow Measurement market was valued at US$ 1693 million in 2023 and is anticipated to reach US$ 2551 million by 2030, witnessing a CAGR of 6.1% during the forecast period 2024-2030. This market outlook indicates a significant growth trajectory for non-intrusive flow measurement technologies over the next several years. The increasing demand for accurate, reliable, and low-maintenance flow measurement solutions across various industries is driving this growth. Non-intrusive flow meters offer several advantages over traditional intrusive methods, including ease of installation, reduced downtime, and the ability to operate under a wide range of conditions. These benefits make them an attractive option for industries such as oil and gas, chemical processing, water treatment, and food and beverage production, where maintaining the integrity of the pipeline and ensuring precise flow measurement are critical. As industries continue to seek ways to optimize their operations and reduce costs, the demand for non-intrusive flow measurement technologies is expected to grow, driving the market's expansion.

| Report Metric | Details |

| Report Name | Non-Intrusive Flow Measurement Market |

| Accounted market size in 2023 | US$ 1693 million |

| Forecasted market size in 2030 | US$ 2551 million |

| CAGR | 6.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KROHNE Group, Endress+Hauser, Emerson, Siemens, Yokogawa Electric, Honeywell, SICK AG, Fuji Electric, Baker Hughes, Pulsar Measurement, Bronkhorst |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |