What is Global Multi-Layer High-Frequency PCB Market?

The Global Multi-Layer High-Frequency PCB Market refers to the industry focused on the production and distribution of printed circuit boards (PCBs) that are designed to operate at high frequencies and consist of multiple layers. These PCBs are essential components in various electronic devices and systems, enabling the transmission of signals at high speeds and with minimal interference. The multi-layer design allows for more complex and compact circuitry, which is crucial for modern electronic applications. High-frequency PCBs are used in a wide range of industries, including telecommunications, consumer electronics, automotive, medical, industrial, and aerospace. They are particularly important in applications where signal integrity and performance are critical, such as in high-speed data communication and advanced radar systems. The market for these PCBs is driven by the increasing demand for high-performance electronic devices and the continuous advancements in technology that require more sophisticated and reliable circuit boards.

Medium Frequency (MF), Very High Frequency (VHF) in the Global Multi-Layer High-Frequency PCB Market:

Medium Frequency (MF) and Very High Frequency (VHF) are two categories of frequency ranges that are significant in the context of the Global Multi-Layer High-Frequency PCB Market. Medium Frequency (MF) typically ranges from 300 kHz to 3 MHz and is commonly used in applications such as AM radio broadcasting, maritime communication, and some types of navigation systems. In the realm of PCBs, MF circuits require careful design to ensure signal integrity and minimize interference, as these frequencies can be susceptible to noise and signal degradation. Multi-layer PCBs are particularly beneficial in MF applications because they allow for better isolation of signals and more efficient use of space, which is crucial for maintaining performance in compact devices. On the other hand, Very High Frequency (VHF) ranges from 30 MHz to 300 MHz and is used in applications such as FM radio broadcasting, television broadcasting, and two-way radio communication. VHF circuits demand even more stringent design considerations due to the higher frequencies involved. At these frequencies, issues such as signal loss, crosstalk, and electromagnetic interference become more pronounced. Multi-layer high-frequency PCBs are essential in VHF applications because they provide the necessary structure to manage these challenges effectively. The multiple layers allow for the separation of signal paths, reducing the risk of interference and ensuring that the signals remain clear and strong. In both MF and VHF applications, the choice of materials for the PCB is critical. High-frequency PCBs often use specialized materials with low dielectric constants and low loss tangents to ensure that the signals can travel with minimal loss and distortion. These materials, combined with advanced manufacturing techniques, enable the production of PCBs that can handle the demands of high-frequency operation. The design of the PCB layout is also crucial, as it must account for factors such as impedance matching, signal routing, and thermal management to ensure optimal performance. The Global Multi-Layer High-Frequency PCB Market is driven by the increasing demand for reliable and high-performance electronic devices across various industries. As technology continues to advance, the need for PCBs that can operate at higher frequencies and with greater complexity will only grow. This demand is particularly evident in the telecommunications industry, where the rollout of 5G networks and other advanced communication technologies require PCBs that can handle high-frequency signals with precision and reliability. Similarly, in the automotive industry, the development of advanced driver-assistance systems (ADAS) and autonomous vehicles relies on high-frequency PCBs to process and transmit data quickly and accurately. In summary, Medium Frequency (MF) and Very High Frequency (VHF) are two important frequency ranges in the Global Multi-Layer High-Frequency PCB Market. MF applications benefit from the multi-layer design of PCBs, which helps to maintain signal integrity and minimize interference. VHF applications require even more advanced PCB designs to manage the challenges of higher frequencies, including signal loss and electromagnetic interference. The choice of materials and the design of the PCB layout are critical factors in ensuring the performance of high-frequency PCBs. As the demand for high-performance electronic devices continues to grow, the market for multi-layer high-frequency PCBs will continue to expand, driven by advancements in technology and the need for reliable and efficient circuit boards.

Communication, Consumer Electronics, Automobile, Medical, Industrial, Aerospace, Others in the Global Multi-Layer High-Frequency PCB Market:

The usage of Global Multi-Layer High-Frequency PCBs spans across various industries, each with its unique requirements and applications. In the field of communication, these PCBs are integral to the functioning of high-speed data transmission systems, including 5G networks, satellite communication, and fiber-optic networks. The multi-layer design allows for the integration of complex circuitry needed to handle high-frequency signals, ensuring minimal signal loss and interference. This is crucial for maintaining the quality and reliability of communication systems, which are essential for both personal and professional use. In consumer electronics, multi-layer high-frequency PCBs are found in devices such as smartphones, tablets, laptops, and gaming consoles. These devices require compact and efficient circuit boards to accommodate the increasing demand for higher processing power and faster data transfer rates. The multi-layer design not only saves space but also enhances the performance of these devices by providing better signal integrity and reducing electromagnetic interference. This results in faster, more reliable, and more efficient electronic devices that meet the growing consumer expectations. The automotive industry also benefits significantly from multi-layer high-frequency PCBs. Modern vehicles are equipped with advanced electronic systems, including infotainment systems, navigation systems, and various sensors for safety and driver assistance. These systems rely on high-frequency PCBs to process and transmit data quickly and accurately. For instance, in advanced driver-assistance systems (ADAS), high-frequency PCBs are used to ensure the rapid processing of data from various sensors, enabling real-time decision-making and enhancing vehicle safety. Additionally, the development of electric and autonomous vehicles further drives the demand for high-performance PCBs to support the complex electronic systems required for these technologies. In the medical field, multi-layer high-frequency PCBs are used in various diagnostic and therapeutic devices. Medical equipment such as MRI machines, ultrasound devices, and patient monitoring systems require precise and reliable electronic components to function effectively. High-frequency PCBs ensure that these devices can operate at the required frequencies with minimal signal loss and interference, which is crucial for accurate diagnostics and effective treatment. The reliability and performance of these PCBs directly impact the quality of healthcare services, making them an essential component in the medical industry. The industrial sector also relies on multi-layer high-frequency PCBs for various applications, including automation systems, robotics, and industrial control systems. These applications require robust and reliable PCBs to handle high-frequency signals and ensure the smooth operation of complex machinery and processes. The multi-layer design provides the necessary structure to manage the high-frequency signals and reduce the risk of interference, ensuring the efficiency and reliability of industrial systems. In the aerospace industry, multi-layer high-frequency PCBs are used in various avionics systems, including communication, navigation, and radar systems. These systems require high-performance PCBs to handle the demanding conditions of aerospace applications, including high frequencies, extreme temperatures, and harsh environments. The multi-layer design ensures that the PCBs can meet these requirements, providing reliable and efficient performance in critical aerospace applications. Other industries, such as defense and security, also benefit from the use of multi-layer high-frequency PCBs. These PCBs are used in various defense systems, including radar, communication, and electronic warfare systems, where high-frequency operation and reliability are crucial. The multi-layer design allows for the integration of complex circuitry needed to handle high-frequency signals, ensuring the performance and reliability of these critical systems. In conclusion, the usage of Global Multi-Layer High-Frequency PCBs spans across various industries, including communication, consumer electronics, automotive, medical, industrial, aerospace, and others. Each industry has unique requirements and applications that benefit from the high-performance and reliability of multi-layer high-frequency PCBs. The multi-layer design allows for the integration of complex circuitry, ensuring minimal signal loss and interference, which is crucial for the performance and reliability of electronic systems in these industries. As technology continues to advance, the demand for high-frequency PCBs will continue to grow, driving the expansion of the Global Multi-Layer High-Frequency PCB Market.

Global Multi-Layer High-Frequency PCB Market Outlook:

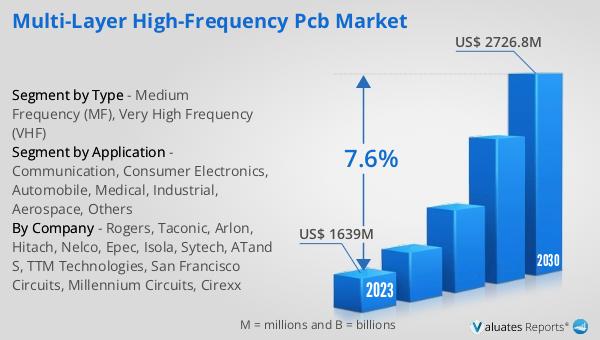

The global Multi-Layer High-Frequency PCB market was valued at US$ 1639 million in 2023 and is anticipated to reach US$ 2726.8 million by 2030, witnessing a CAGR of 7.6% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of the multi-layer high-frequency PCB market over the next several years. The increasing demand for high-performance electronic devices across various industries, including telecommunications, consumer electronics, automotive, medical, industrial, and aerospace, is driving this growth. The advancements in technology and the need for reliable and efficient circuit boards to support these advancements are also contributing to the market's expansion. The projected growth rate of 7.6% CAGR indicates a robust and steady increase in the market value, reflecting the rising importance of multi-layer high-frequency PCBs in modern electronic applications. As the market continues to grow, manufacturers and suppliers of high-frequency PCBs will need to focus on innovation and quality to meet the evolving demands of their customers. This growth trajectory underscores the critical role that multi-layer high-frequency PCBs play in enabling the development and deployment of advanced electronic systems and technologies.

| Report Metric | Details |

| Report Name | Multi-Layer High-Frequency PCB Market |

| Accounted market size in 2023 | US$ 1639 million |

| Forecasted market size in 2030 | US$ 2726.8 million |

| CAGR | 7.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Rogers, Taconic, Arlon, Hitach, Nelco, Epec, Isola, Sytech, ATand S, TTM Technologies, San Francisco Circuits, Millennium Circuits, Cirexx |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |