What is Global Metallized LDPE Film Market?

The Global Metallized LDPE Film Market refers to the worldwide industry involved in the production, distribution, and utilization of low-density polyethylene (LDPE) films that have been metallized. Metallization is a process where a thin layer of metal, typically aluminum, is applied to the surface of the LDPE film. This process enhances the film's barrier properties, making it more resistant to moisture, oxygen, and light, which is crucial for preserving the quality and extending the shelf life of various products. These films are widely used in packaging, particularly for food and beverages, due to their excellent protective qualities. Additionally, they find applications in other sectors such as electronics, medical, and industrial uses. The market for metallized LDPE films is driven by the increasing demand for high-performance packaging materials that can offer superior protection and aesthetic appeal. As consumer preferences shift towards more durable and visually appealing packaging, the demand for metallized LDPE films is expected to grow. The market is also influenced by advancements in metallization technology, which have made the production process more efficient and cost-effective.

Bright, Matte in the Global Metallized LDPE Film Market:

In the context of the Global Metallized LDPE Film Market, the terms "Bright" and "Matte" refer to the finish or appearance of the metallized film. Bright metallized LDPE films have a shiny, reflective surface that enhances the visual appeal of the packaging. This type of finish is particularly popular in the food and beverage industry, where it is used to create eye-catching packaging that stands out on store shelves. The bright finish not only improves the aesthetic appeal but also provides excellent barrier properties, protecting the contents from moisture, oxygen, and light. On the other hand, matte metallized LDPE films have a non-reflective, dull surface that offers a more subdued and sophisticated look. This type of finish is often preferred in the electronics and medical industries, where a less flashy appearance is desired. Matte films still provide the same level of protection as bright films but with a different visual effect. The choice between bright and matte finishes depends on the specific requirements of the application and the desired aesthetic outcome. Both types of finishes are produced using advanced metallization techniques that ensure uniform coating and high-quality performance. The growing demand for customized packaging solutions has led to an increase in the production of both bright and matte metallized LDPE films. Manufacturers are continuously innovating to develop new finishes and textures that meet the evolving needs of various industries. The versatility of metallized LDPE films, combined with their superior protective qualities, makes them a popular choice for a wide range of applications. As the market continues to expand, the demand for both bright and matte finishes is expected to rise, driven by the need for high-performance packaging materials that offer both functionality and visual appeal.

Food and Beverage, Electricals and Electronics, Medical Industry, Others in the Global Metallized LDPE Film Market:

The Global Metallized LDPE Film Market finds extensive usage across various industries, including Food and Beverage, Electricals and Electronics, Medical Industry, and others. In the Food and Beverage sector, metallized LDPE films are primarily used for packaging due to their excellent barrier properties. These films protect food products from moisture, oxygen, and light, thereby extending their shelf life and maintaining their quality. They are commonly used for packaging snacks, confectionery, dairy products, and beverages. The shiny, reflective surface of bright metallized films also enhances the visual appeal of the packaging, making it more attractive to consumers. In the Electricals and Electronics industry, metallized LDPE films are used for insulation and protective packaging. These films provide excellent electrical insulation properties, making them suitable for wrapping electronic components and devices. They also offer protection against static electricity, which is crucial for sensitive electronic equipment. In the Medical Industry, metallized LDPE films are used for packaging medical devices, pharmaceuticals, and other healthcare products. The films provide a sterile barrier that protects the contents from contamination and ensures their safety and efficacy. The matte finish is often preferred in this industry due to its non-reflective surface, which reduces glare and makes it easier to read labels and instructions. Other industries that use metallized LDPE films include the automotive, construction, and textile sectors. In the automotive industry, these films are used for insulation and protective wrapping of various components. In the construction industry, they are used for vapor barriers and insulation materials. In the textile industry, metallized LDPE films are used for packaging and protective wrapping of fabrics and garments. The versatility and superior protective qualities of metallized LDPE films make them a popular choice across these diverse industries. As the demand for high-performance packaging materials continues to grow, the usage of metallized LDPE films is expected to increase in these and other sectors.

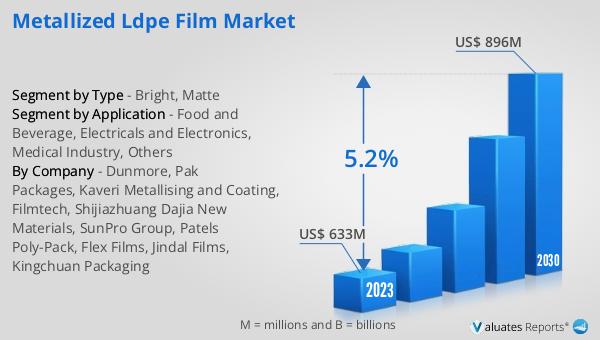

Global Metallized LDPE Film Market Outlook:

The global Metallized LDPE Film market was valued at US$ 633 million in 2023 and is anticipated to reach US$ 896 million by 2030, witnessing a CAGR of 5.2% during the forecast period from 2024 to 2030. This significant growth reflects the increasing demand for high-performance packaging materials across various industries. The market's expansion is driven by the superior barrier properties of metallized LDPE films, which protect products from moisture, oxygen, and light, thereby extending their shelf life and maintaining their quality. The shiny, reflective surface of bright metallized films enhances the visual appeal of packaging, making it more attractive to consumers, particularly in the food and beverage sector. Meanwhile, the matte finish is preferred in industries such as electronics and medical, where a less flashy appearance is desired. The continuous innovation in metallization technology has made the production process more efficient and cost-effective, further boosting the market's growth. As consumer preferences shift towards more durable and visually appealing packaging, the demand for metallized LDPE films is expected to rise. The market's positive outlook is also supported by the increasing usage of these films in other sectors such as automotive, construction, and textiles. Overall, the global Metallized LDPE Film market is poised for substantial growth in the coming years, driven by the need for high-performance packaging solutions that offer both functionality and aesthetic appeal.

| Report Metric | Details |

| Report Name | Metallized LDPE Film Market |

| Accounted market size in 2023 | US$ 633 million |

| Forecasted market size in 2030 | US$ 896 million |

| CAGR | 5.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dunmore, Pak Packages, Kaveri Metallising and Coating, Filmtech, Shijiazhuang Dajia New Materials, SunPro Group, Patels Poly-Pack, Flex Films, Jindal Films, Kingchuan Packaging |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |