What is Global Hydrogen Storage High-Entropy Alloys Market?

The Global Hydrogen Storage High-Entropy Alloys Market is a rapidly evolving sector that focuses on the development and commercialization of advanced materials designed to store hydrogen efficiently. High-entropy alloys (HEAs) are a new class of materials composed of five or more elements in near-equal proportions, which offer unique properties such as high strength, corrosion resistance, and excellent hydrogen storage capabilities. These alloys are particularly significant in the context of hydrogen storage because they can absorb and release hydrogen at lower pressures and temperatures compared to traditional materials. This makes them highly suitable for various applications, including fuel cells, hydrogen-powered vehicles, and renewable energy storage systems. The market for these advanced materials is driven by the increasing demand for clean energy solutions and the need to reduce greenhouse gas emissions. As countries and industries worldwide strive to transition to more sustainable energy sources, the role of high-entropy alloys in hydrogen storage is expected to become increasingly important.

Powder, Rod, Plate, Others in the Global Hydrogen Storage High-Entropy Alloys Market:

In the Global Hydrogen Storage High-Entropy Alloys Market, products are typically categorized into four main types: powder, rod, plate, and others. Each of these forms has distinct characteristics and applications. Powdered high-entropy alloys are often used in research and development settings due to their versatility and ease of handling. They can be compacted and sintered into various shapes, making them ideal for experimental studies and small-scale production. Rods, on the other hand, are more commonly used in industrial applications where structural integrity and mechanical strength are crucial. These rods can be machined into specific components for use in hydrogen storage systems, fuel cells, and other energy-related devices. Plates of high-entropy alloys are typically employed in applications requiring large surface areas, such as heat exchangers and hydrogen storage tanks. The flat, expansive nature of plates allows for efficient heat transfer and hydrogen absorption, making them suitable for large-scale energy storage solutions. Other forms of high-entropy alloys, which may include wires, foils, or custom shapes, are used in specialized applications where unique material properties are required. These could range from aerospace components to advanced chemical processing equipment. The choice of form depends largely on the specific requirements of the application, including factors such as mechanical strength, thermal conductivity, and hydrogen absorption capacity. Each form of high-entropy alloy offers unique advantages, making them versatile materials for a wide range of hydrogen storage applications.

New Energies, Electric Power, Aerospace, Chemical, Others in the Global Hydrogen Storage High-Entropy Alloys Market:

The usage of Global Hydrogen Storage High-Entropy Alloys Market spans several key areas, including new energies, electric power, aerospace, chemical, and others. In the realm of new energies, these alloys are pivotal in the development of hydrogen fuel cells and storage systems, which are essential for the transition to renewable energy sources. They enable efficient storage and release of hydrogen, facilitating the use of hydrogen as a clean energy carrier. In the electric power sector, high-entropy alloys are used in hydrogen storage systems that support grid stability and energy storage solutions. These systems can store excess energy generated from renewable sources like wind and solar, and release it when needed, thereby enhancing the reliability and efficiency of the power grid. In aerospace, the lightweight and high-strength properties of high-entropy alloys make them ideal for use in hydrogen storage tanks and other components of hydrogen-powered aircraft. This not only reduces the weight of the aircraft but also increases its fuel efficiency and range. In the chemical industry, these alloys are used in hydrogenation processes and other chemical reactions that require efficient hydrogen storage and release. Their resistance to corrosion and high temperatures makes them suitable for harsh chemical environments. Other applications of high-entropy alloys in hydrogen storage include their use in advanced manufacturing processes, automotive industries, and various research and development projects. The versatility and unique properties of these materials make them indispensable in a wide range of industries seeking to leverage hydrogen as a sustainable energy source.

Global Hydrogen Storage High-Entropy Alloys Market Outlook:

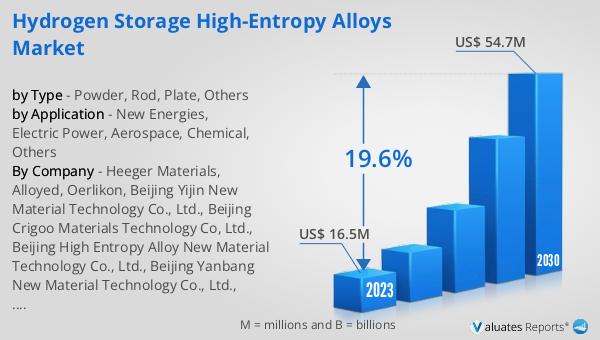

The global Hydrogen Storage High-Entropy Alloys market was valued at US$ 16.5 million in 2023 and is anticipated to reach US$ 54.7 million by 2030, witnessing a CAGR of 19.6% during the forecast period 2024-2030. This significant growth reflects the increasing demand for advanced hydrogen storage solutions driven by the global shift towards renewable energy and sustainable practices. High-entropy alloys, with their superior hydrogen storage capabilities, are at the forefront of this transition. The market's expansion is fueled by ongoing research and development efforts aimed at enhancing the performance and cost-effectiveness of these materials. As industries and governments worldwide invest in clean energy technologies, the demand for high-entropy alloys in hydrogen storage applications is expected to rise substantially. This growth trajectory underscores the critical role of high-entropy alloys in the future of energy storage and the broader efforts to combat climate change.

| Report Metric | Details |

| Report Name | Hydrogen Storage High-Entropy Alloys Market |

| Accounted market size in 2023 | US$ 16.5 million |

| Forecasted market size in 2030 | US$ 54.7 million |

| CAGR | 19.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Heeger Materials, Alloyed, Oerlikon, Beijing Yijin New Material Technology Co., Ltd., Beijing Crigoo Materials Technology Co, Ltd., Beijing High Entropy Alloy New Material Technology Co., Ltd., Beijing Yanbang New Material Technology Co., Ltd., Shanghai Truer, Metalysis, Stanford Advanced Materials, ATT Advanced Elemental Materials Co., Ltd., Jiangxi Yongtai Powder Metallurgy Co., Ltd., STARDUST, GREES (BEIJING) NEW MATERIAL TECHNOLOGY CO., LTD. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |