What is Global Directly Buried Insulated Pipes Market?

The Global Directly Buried Insulated Pipes Market refers to the industry that manufactures and supplies insulated pipes designed to be buried directly underground without the need for additional protective measures. These pipes are primarily used for transporting hot and cold fluids, such as water, steam, and oil, while maintaining their temperature over long distances. The insulation helps to minimize heat loss or gain, ensuring energy efficiency and cost savings. These pipes are commonly used in district heating and cooling systems, industrial processes, and various infrastructure projects. The market for directly buried insulated pipes is driven by the growing demand for energy-efficient solutions, the need for reliable and durable piping systems, and the increasing focus on sustainable infrastructure development. The market encompasses various types of insulated pipes, including plastic-sheathed steel insulation pipes, steel outer protective pipe vacuum composite insulation prefabricated direct buried pipes, and steel jacketed steel insulation pipes, each offering unique benefits and applications.

Plastic Sheathed Steel Insulation Pipe, Steel Outer Protective Pipe Vacuum Composite Insulation Prefabricated Direct Buried Pipe, Steel Jacketed Steel Insulation Pipe in the Global Directly Buried Insulated Pipes Market:

Plastic Sheathed Steel Insulation Pipe is a type of directly buried insulated pipe that features a steel pipe core surrounded by a layer of insulation material, which is then encased in a plastic sheath. This design provides excellent thermal insulation, corrosion resistance, and mechanical protection, making it suitable for various applications, including district heating and cooling systems. The plastic sheath acts as a barrier against moisture and other environmental factors, ensuring the longevity and reliability of the pipe. Steel Outer Protective Pipe Vacuum Composite Insulation Prefabricated Direct Buried Pipe is another type of insulated pipe that consists of a steel pipe core, an insulation layer, and an outer protective steel pipe. The insulation layer is typically made of materials such as polyurethane foam, which provides high thermal resistance. The outer steel pipe offers additional mechanical protection and durability, making it ideal for harsh environments and heavy-duty applications. The vacuum composite insulation further enhances the thermal performance by reducing heat transfer through the insulation layer. Steel Jacketed Steel Insulation Pipe is a robust and durable type of directly buried insulated pipe that features a steel pipe core, an insulation layer, and an outer steel jacket. This design provides superior mechanical strength and protection against external damage, making it suitable for high-pressure and high-temperature applications. The steel jacket also offers excellent resistance to corrosion and environmental factors, ensuring the longevity and reliability of the pipe. These various types of directly buried insulated pipes cater to different needs and applications, providing energy-efficient and cost-effective solutions for transporting fluids over long distances.

Heating, Petroleum and Natural Gas, Chemical Industry, Electric Power, Others in the Global Directly Buried Insulated Pipes Market:

The Global Directly Buried Insulated Pipes Market finds extensive usage in various sectors, including heating, petroleum and natural gas, chemical industry, electric power, and others. In the heating sector, these insulated pipes are widely used in district heating systems to transport hot water or steam from central heating plants to residential, commercial, and industrial buildings. The insulation helps to minimize heat loss during transportation, ensuring energy efficiency and cost savings. In the petroleum and natural gas industry, directly buried insulated pipes are used to transport oil, gas, and other hydrocarbons over long distances. The insulation helps to maintain the temperature of the transported fluids, preventing heat loss or gain and ensuring the integrity and efficiency of the transportation process. In the chemical industry, these pipes are used to transport various chemicals and fluids that require temperature control. The insulation helps to maintain the desired temperature, ensuring the stability and quality of the transported chemicals. In the electric power sector, directly buried insulated pipes are used in district cooling systems to transport chilled water for air conditioning and cooling purposes. The insulation helps to minimize heat gain during transportation, ensuring energy efficiency and cost savings. Other applications of directly buried insulated pipes include industrial processes, infrastructure projects, and various other sectors that require efficient and reliable fluid transportation systems. The growing demand for energy-efficient solutions, the need for reliable and durable piping systems, and the increasing focus on sustainable infrastructure development are driving the adoption of directly buried insulated pipes in these various sectors.

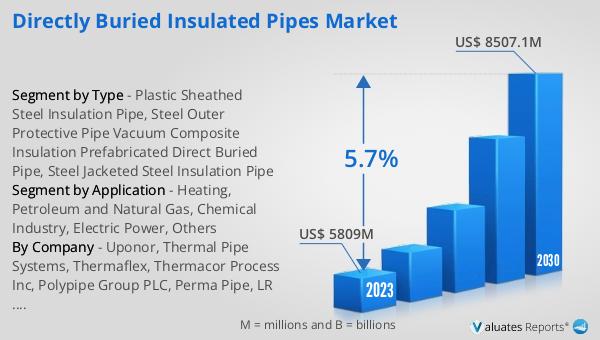

Global Directly Buried Insulated Pipes Market Outlook:

The global Directly Buried Insulated Pipes market was valued at US$ 5809 million in 2023 and is anticipated to reach US$ 8507.1 million by 2030, witnessing a CAGR of 5.7% during the forecast period 2024-2030. This significant growth is driven by the increasing demand for energy-efficient and cost-effective piping solutions across various sectors, including heating, petroleum and natural gas, chemical industry, electric power, and others. The market is also influenced by the growing focus on sustainable infrastructure development and the need for reliable and durable piping systems. The adoption of directly buried insulated pipes is expected to continue to rise as industries and governments worldwide seek to improve energy efficiency, reduce operational costs, and enhance the reliability and longevity of their infrastructure. The market encompasses various types of insulated pipes, including plastic-sheathed steel insulation pipes, steel outer protective pipe vacuum composite insulation prefabricated direct buried pipes, and steel jacketed steel insulation pipes, each offering unique benefits and applications. The increasing awareness of the benefits of directly buried insulated pipes, such as reduced heat loss or gain, improved energy efficiency, and cost savings, is expected to further drive the market growth during the forecast period.

| Report Metric | Details |

| Report Name | Directly Buried Insulated Pipes Market |

| Accounted market size in 2023 | US$ 5809 million |

| Forecasted market size in 2030 | US$ 8507.1 million |

| CAGR | 5.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Uponor, Thermal Pipe Systems, Thermaflex, Thermacor Process Inc, Polypipe Group PLC, Perma Pipe, LR Marine A/S, Logstor, Isoplus, Insul-Tek Piping Systems Inc, Georg Fischer AG, Brugg Group AG, World Iron & Steel Co.,Ltd, Union Victory (HK) Industry, Guangzhou Mayer Corp |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |