What is Global 75% Nickel Coated Graphite Market?

The Global 75% Nickel Coated Graphite Market refers to the industry focused on the production and distribution of graphite particles that are coated with 75% nickel. This specialized material is highly valued for its unique properties, such as excellent electrical conductivity, thermal stability, and corrosion resistance. These characteristics make it an essential component in various high-tech applications, including electronics, aerospace, and automotive industries. The nickel coating enhances the graphite's performance by providing a protective layer that prevents oxidation and wear, thereby extending the material's lifespan and reliability. The market for this material is driven by the increasing demand for advanced materials that can meet the stringent requirements of modern technology. As industries continue to innovate and develop new applications, the need for high-performance materials like 75% nickel-coated graphite is expected to grow. This market encompasses a wide range of products, from raw materials to finished components, and involves numerous stakeholders, including manufacturers, suppliers, and end-users. The global reach of this market highlights its significance in the broader context of technological advancement and industrial development.

Spherical, Flake in the Global 75% Nickel Coated Graphite Market:

In the Global 75% Nickel Coated Graphite Market, the material can be categorized based on its physical form, primarily into spherical and flake types. Spherical nickel-coated graphite particles are characterized by their round shape, which provides a uniform surface area and consistent performance in applications requiring high precision and reliability. These spherical particles are particularly useful in applications such as conductive coatings and adhesives, where their shape allows for better dispersion and uniformity. The spherical form also enhances the material's flow properties, making it easier to process and apply in various manufacturing techniques. On the other hand, flake nickel-coated graphite particles have a layered structure that offers a larger surface area compared to spherical particles. This increased surface area can enhance the material's electrical and thermal conductivity, making it ideal for applications such as electromagnetic shielding and electronic packaging. The flake form is also beneficial in applications where a higher degree of mechanical flexibility is required, as the layered structure can provide better adaptability to different shapes and surfaces. Both spherical and flake forms of nickel-coated graphite have their unique advantages and are chosen based on the specific requirements of the application. The choice between spherical and flake forms depends on factors such as the desired electrical and thermal properties, mechanical strength, and ease of processing. In the context of the Global 75% Nickel Coated Graphite Market, the availability of both forms allows manufacturers and end-users to select the most suitable material for their specific needs, thereby optimizing performance and efficiency. The versatility of nickel-coated graphite in both spherical and flake forms underscores its importance in various high-tech industries, where advanced materials are crucial for innovation and development. As the demand for high-performance materials continues to rise, the market for both spherical and flake nickel-coated graphite is expected to grow, driven by the need for reliable and efficient solutions in a wide range of applications.

Electromagnetic Shielding Materials, Conductive Coating, Conductive Adhesive, Electronic Packaging, Others in the Global 75% Nickel Coated Graphite Market:

The Global 75% Nickel Coated Graphite Market finds extensive usage in several critical areas, including electromagnetic shielding materials, conductive coatings, conductive adhesives, electronic packaging, and other specialized applications. In the realm of electromagnetic shielding materials, nickel-coated graphite is highly effective due to its excellent electrical conductivity and magnetic properties. It is used to create barriers that protect sensitive electronic equipment from electromagnetic interference (EMI), ensuring the proper functioning of devices in environments with high levels of electromagnetic radiation. This is particularly important in industries such as telecommunications, aerospace, and defense, where reliable performance is crucial. Conductive coatings made from nickel-coated graphite are used to enhance the electrical conductivity of surfaces, providing a cost-effective solution for applications requiring efficient electrical pathways. These coatings are applied to various substrates, including plastics and metals, to improve their conductivity and protect against corrosion. In the field of conductive adhesives, nickel-coated graphite particles are used to create adhesives that can conduct electricity, making them ideal for bonding electronic components. These adhesives provide a reliable connection while also offering flexibility and ease of application, which is essential in the assembly of complex electronic devices. Electronic packaging is another significant area where nickel-coated graphite is utilized. The material's thermal and electrical properties make it suitable for use in packaging solutions that protect electronic components from heat and electrical interference. This ensures the longevity and reliability of electronic devices, which is critical in consumer electronics, automotive, and industrial applications. Beyond these primary uses, nickel-coated graphite is also employed in other specialized applications, such as in the production of sensors, batteries, and fuel cells. Its unique combination of properties makes it a versatile material that can meet the demanding requirements of various high-tech industries. The widespread usage of 75% nickel-coated graphite in these areas highlights its importance as a key material in the advancement of modern technology.

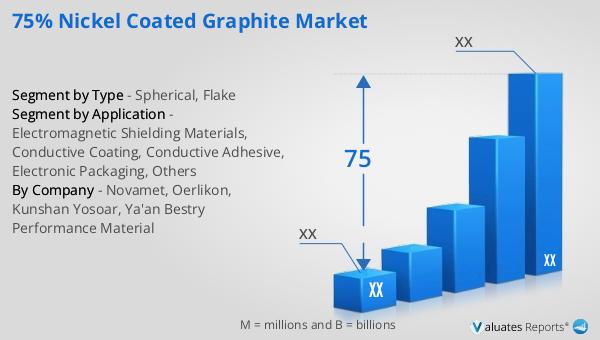

Global 75% Nickel Coated Graphite Market Outlook:

The global market for 75% Nickel Coated Graphite was valued at an undisclosed amount in 2023 and is projected to reach another undisclosed amount by 2030, reflecting a compound annual growth rate (CAGR) over the forecast period from 2024 to 2030. In North America, the market for 75% Nickel Coated Graphite is expected to grow from an undisclosed amount in 2023 to another undisclosed amount by 2030, also witnessing a CAGR over the same forecast period. Similarly, the Asia-Pacific region is anticipated to see its market size increase from an undisclosed amount in 2023 to another undisclosed amount by 2030, maintaining a CAGR throughout the forecast period from 2024 to 2030. Key global manufacturers in this market include notable companies such as Novamet, Oerlikon, Kunshan Yosoar, and Yaan Bestry Performance Material. These companies play a significant role in driving the market forward through their innovations and high-quality products. The market outlook underscores the growing importance of 75% Nickel Coated Graphite in various high-tech applications and its potential for continued growth in the coming years.

| Report Metric | Details |

| Report Name | 75% Nickel Coated Graphite Market |

| CAGR | 75 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Novamet, Oerlikon, Kunshan Yosoar, Ya'an Bestry Performance Material |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |