What is Global High-Temperature Fatigue Testing Machine Market?

The Global High-Temperature Fatigue Testing Machine Market is a specialized segment within the broader testing equipment industry, focusing on machines designed to evaluate the durability and performance of materials under high-temperature conditions. These machines are crucial for industries where materials are subjected to extreme heat and stress, such as aerospace, automotive, and energy sectors. High-temperature fatigue testing machines simulate the conditions materials face in real-world applications, allowing researchers and engineers to understand how materials will behave over time. This understanding is vital for ensuring safety, reliability, and efficiency in various applications. The market for these machines is driven by the increasing demand for advanced materials that can withstand harsh environments, as well as the need for rigorous testing to meet stringent industry standards. As industries continue to innovate and push the boundaries of material science, the demand for high-temperature fatigue testing machines is expected to grow, making it a dynamic and evolving market. The machines are equipped with advanced features such as precise temperature control, data acquisition systems, and software for analyzing test results, which enhance their functionality and appeal to end-users.

Constant Amplitude Fatigue Test, Variable Frequency Fatigue Test, Random Fatigue Test, Programmed Fatigue Test, Other in the Global High-Temperature Fatigue Testing Machine Market:

In the realm of high-temperature fatigue testing, several methodologies are employed to assess the endurance and performance of materials under cyclic loading conditions. The Constant Amplitude Fatigue Test is one of the most straightforward methods, where a material is subjected to repeated loading and unloading cycles at a constant amplitude until failure occurs. This test helps in understanding the fatigue life of materials under uniform stress conditions, providing valuable data on how long a material can withstand repeated stress before it fails. On the other hand, the Variable Frequency Fatigue Test involves varying the frequency of the applied load cycles. This method is particularly useful for simulating real-world conditions where materials experience fluctuating stresses, such as in automotive or aerospace applications. By altering the frequency, researchers can gain insights into how materials respond to different stress rates, which is crucial for designing components that can endure variable operational conditions. The Random Fatigue Test takes this a step further by applying loads in a random sequence, mimicking the unpredictable nature of real-world stressors. This test is essential for industries where materials are exposed to irregular and unpredictable forces, providing a comprehensive understanding of material behavior under such conditions. Programmed Fatigue Tests are designed to simulate specific operational scenarios by applying a predetermined sequence of loads. This method is particularly beneficial for industries like aerospace, where components must endure specific stress patterns during flight. By programming the test to replicate these conditions, engineers can ensure that materials will perform reliably in their intended applications. Other testing methods in the high-temperature fatigue testing machine market include specialized tests tailored to unique industry requirements. These may involve testing under multi-axial loading conditions, where materials are subjected to stresses from multiple directions simultaneously, or tests that incorporate environmental factors such as humidity or corrosive elements. Each of these testing methodologies plays a crucial role in advancing material science and engineering, providing the data needed to develop materials that can withstand the rigors of high-temperature environments. As industries continue to innovate and demand more from their materials, the importance of these testing methods will only grow, driving further advancements in high-temperature fatigue testing technology.

Automotive, Aerospace, Energy & Power, Materials Science Research, Other in the Global High-Temperature Fatigue Testing Machine Market:

The Global High-Temperature Fatigue Testing Machine Market finds extensive applications across various industries, each with its unique requirements and challenges. In the automotive sector, these machines are crucial for testing the durability and performance of materials used in engines, exhaust systems, and other components that are exposed to high temperatures and cyclic stresses. By simulating the harsh conditions these components face, manufacturers can ensure that their products meet safety and performance standards, ultimately leading to more reliable and efficient vehicles. In the aerospace industry, high-temperature fatigue testing machines are indispensable for evaluating the materials used in aircraft engines, turbine blades, and other critical components. The ability to withstand high temperatures and cyclic loading is essential for ensuring the safety and reliability of aircraft, making these tests a vital part of the design and manufacturing process. The energy and power sector also relies heavily on high-temperature fatigue testing machines to assess the performance of materials used in power plants, particularly in turbines and boilers where materials are subjected to extreme heat and stress. By understanding how these materials behave under such conditions, engineers can design more efficient and durable power generation systems. In the field of materials science research, high-temperature fatigue testing machines are used to explore the properties and potential applications of new materials. Researchers can simulate various environmental conditions to study how materials respond, providing valuable insights that drive innovation and development in material science. Other industries, such as construction and manufacturing, also benefit from these machines, using them to test materials that must endure high temperatures and cyclic stresses in their applications. Overall, the Global High-Temperature Fatigue Testing Machine Market plays a critical role in ensuring the safety, reliability, and efficiency of products across a wide range of industries, supporting innovation and advancement in material science and engineering.

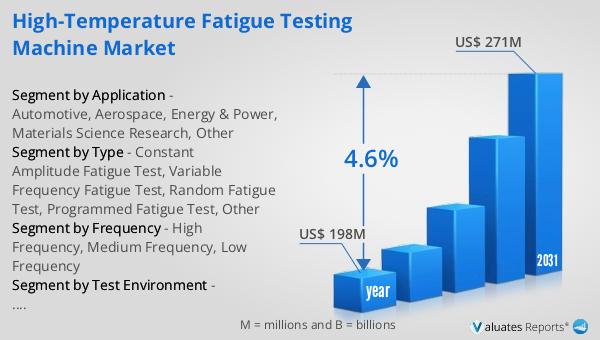

Global High-Temperature Fatigue Testing Machine Market Outlook:

The global market for High-Temperature Fatigue Testing Machines was valued at $198 million in 2024, with projections indicating it will grow to a revised size of $271 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.6% over the forecast period. This upward trend is driven by the increasing demand for advanced materials capable of withstanding extreme conditions, as well as the need for rigorous testing to meet industry standards. As industries such as aerospace, automotive, and energy continue to push the boundaries of material science, the demand for high-temperature fatigue testing machines is expected to rise. These machines are essential for ensuring the safety, reliability, and efficiency of materials used in high-stress environments. The market's growth is also supported by technological advancements in testing equipment, which enhance the accuracy and efficiency of fatigue testing. As a result, the Global High-Temperature Fatigue Testing Machine Market is poised for continued expansion, driven by the ongoing need for innovative materials and the critical role these machines play in material testing and development.

| Report Metric | Details |

| Report Name | High-Temperature Fatigue Testing Machine Market |

| Accounted market size in year | US$ 198 million |

| Forecasted market size in 2031 | US$ 271 million |

| CAGR | 4.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Degree of Automation |

|

| Segment by Test Environment |

|

| Segment by Frequency |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Instron, ZwickRoell, MTS, Shimadzu, HST Group, Jinan KASON Instrument, Sinter, Fuletest, LSI, SUNS, Jinan Zhongluchang Testing Machine Manufacturing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |