What is Global Internally Heated Rotary Kiln Market?

The Global Internally Heated Rotary Kiln Market is a specialized segment within the industrial equipment sector, focusing on the production and sale of rotary kilns that utilize internal heating mechanisms. These kilns are essential in various industrial processes, providing a controlled environment for the thermal treatment of materials. Internally heated rotary kilns are designed to efficiently process materials at high temperatures, making them indispensable in industries such as metallurgy, building materials, chemicals, and environmental protection. The market for these kilns is driven by the demand for efficient and sustainable industrial processes, as they offer advantages such as reduced energy consumption and improved product quality. The global market is characterized by a diverse range of products, each tailored to specific industrial needs, and is supported by advancements in technology that enhance the performance and efficiency of these kilns. As industries continue to seek ways to optimize their operations and reduce their environmental impact, the demand for internally heated rotary kilns is expected to grow, making this market a vital component of the broader industrial equipment landscape.

Gas-fired Iinternal Heating Type, Oil-fired Internal Heating Type, Pulverized Coal Internal Heating Type in the Global Internally Heated Rotary Kiln Market:

The Global Internally Heated Rotary Kiln Market is segmented based on the type of internal heating used, which includes gas-fired, oil-fired, and pulverized coal internal heating types. Each type offers unique advantages and is suited to specific industrial applications. Gas-fired internal heating type kilns are popular due to their efficiency and cleaner combustion process. They utilize natural gas as a fuel source, which burns cleaner than other fossil fuels, resulting in lower emissions and reduced environmental impact. This makes them an attractive option for industries that prioritize sustainability and regulatory compliance. Gas-fired kilns are often used in applications where precise temperature control is essential, as they offer excellent heat distribution and can be easily adjusted to meet specific process requirements.

Metallurgical Industry, Building Materials Industry, Chemical Industry, Environmental Protection Industry, Others in the Global Internally Heated Rotary Kiln Market:

Oil-fired internal heating type kilns, on the other hand, use oil as a fuel source. These kilns are known for their high thermal efficiency and ability to reach very high temperatures, making them suitable for processes that require intense heat. Oil-fired kilns are often used in industries where the cost of natural gas is prohibitive or where oil is more readily available. They offer a reliable and consistent heat source, which is crucial for maintaining product quality in high-temperature applications. However, they may produce higher emissions compared to gas-fired kilns, which can be a consideration for industries with strict environmental regulations.

Global Internally Heated Rotary Kiln Market Outlook:

Pulverized coal internal heating type kilns utilize finely ground coal as a fuel source. These kilns are favored in regions where coal is abundant and cost-effective. Pulverized coal kilns are capable of achieving high temperatures and are often used in heavy industries such as cement and steel production. They offer a cost-effective solution for industries that require large-scale thermal processing, but they also pose challenges in terms of emissions and environmental impact. Advances in technology have led to the development of more efficient and cleaner-burning coal-fired kilns, which help mitigate some of these concerns. Each type of internally heated rotary kiln offers distinct advantages and challenges, and the choice of kiln depends on factors such as fuel availability, cost, environmental regulations, and specific industrial requirements.

| Report Metric | Details |

| Report Name | Internally Heated Rotary Kiln Market |

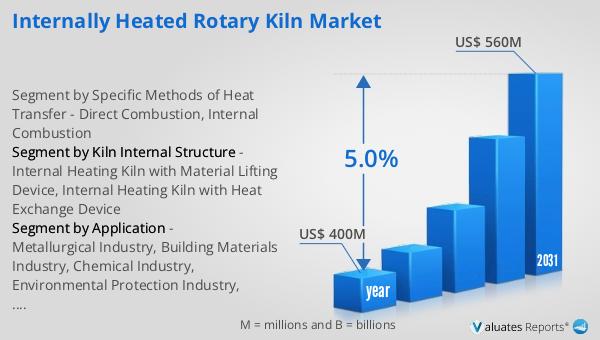

| Accounted market size in year | US$ 400 million |

| Forecasted market size in 2031 | US$ 560 million |

| CAGR | 5.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Kiln Internal Structure |

|

| Segment by Specific Methods of Heat Transfer |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | HiTemp Technology, FEECO International, Inc, ANIVI Ingeniería, Aswathi Industries Limited, Forstar Engineers, Heatmaster International, Thermal Processing Solutions, Inc, Nanjing New Zhongci Magnet-Electric Technology Engineering Co., Ltd, Suzhou Zhongcai Non-metallic Minerals Industry Design & Research Institute Co., Ltd, Jiangsu Dage Environmental Technology Co., Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |