What is Global Semi-Dull Chips Market?

The Global Semi-Dull Chips Market is a specialized segment within the broader chemical and materials industry, focusing on the production and distribution of semi-dull chips. These chips are essential raw materials used in the manufacturing of various textile fibers, including nylon and polyester. Semi-dull chips are characterized by their unique ability to impart a semi-matte finish to the fibers, which is highly desirable in the textile industry for producing fabrics with a subtle sheen and reduced gloss. This market is driven by the growing demand for high-quality textiles in fashion, home furnishings, and industrial applications. The versatility of semi-dull chips makes them a preferred choice for manufacturers looking to enhance the aesthetic appeal and functionality of their products. As consumer preferences continue to evolve, the demand for semi-dull chips is expected to grow, driven by innovations in textile manufacturing and the increasing emphasis on sustainable and eco-friendly production processes. The market's growth is also supported by advancements in technology that enable the production of high-performance fibers with enhanced durability and comfort. Overall, the Global Semi-Dull Chips Market plays a crucial role in the textile industry, providing essential materials that contribute to the development of innovative and high-quality textile products.

Nylon 6 Semi-Dull Chips, Polyester Semi-Dull Chips, Others in the Global Semi-Dull Chips Market:

Nylon 6 Semi-Dull Chips, Polyester Semi-Dull Chips, and other types of semi-dull chips are integral components of the Global Semi-Dull Chips Market, each serving distinct purposes and applications. Nylon 6 Semi-Dull Chips are primarily used in the production of nylon fibers, which are known for their strength, elasticity, and resistance to abrasion. These properties make nylon fibers ideal for a wide range of applications, including apparel, carpets, and industrial products. The semi-dull finish of Nylon 6 chips provides a balanced aesthetic, offering a soft sheen that enhances the visual appeal of the final product without being overly glossy. This makes them particularly popular in the fashion industry, where the demand for versatile and durable fabrics is high. Polyester Semi-Dull Chips, on the other hand, are used to produce polyester fibers, which are valued for their durability, wrinkle resistance, and ease of care. Polyester fibers are widely used in clothing, home textiles, and technical textiles, offering a cost-effective solution for manufacturers seeking to produce high-quality products. The semi-dull finish of polyester chips adds a subtle luster to the fibers, making them suitable for a variety of applications where a refined appearance is desired. In addition to Nylon 6 and Polyester Semi-Dull Chips, the market also includes other types of semi-dull chips, which cater to specific needs and preferences within the textile industry. These may include chips made from other synthetic polymers or blends, each offering unique properties and benefits. The diversity of semi-dull chips available in the market allows manufacturers to select the most appropriate materials for their specific applications, ensuring that the final products meet the desired performance and aesthetic criteria. As the demand for high-quality textiles continues to grow, the Global Semi-Dull Chips Market is expected to expand, driven by innovations in material science and the increasing emphasis on sustainable production practices. Manufacturers are continually exploring new ways to enhance the properties of semi-dull chips, such as improving their environmental footprint and developing new formulations that offer enhanced performance characteristics. This ongoing innovation is crucial for meeting the evolving needs of the textile industry and ensuring that semi-dull chips remain a vital component of modern textile manufacturing.

Semi-Dull Filament, Semi-Dull Staple Fiber in the Global Semi-Dull Chips Market:

The Global Semi-Dull Chips Market plays a significant role in the production of semi-dull filament and semi-dull staple fiber, both of which are essential components in the textile industry. Semi-dull filament is a continuous fiber that is used in the production of various textile products, including apparel, home textiles, and industrial fabrics. The semi-dull finish of the filament provides a subtle sheen that enhances the aesthetic appeal of the final product, making it suitable for a wide range of applications. The use of semi-dull filament is particularly prevalent in the fashion industry, where the demand for high-quality, visually appealing fabrics is high. The versatility of semi-dull filament allows manufacturers to create fabrics with a soft hand feel, excellent drape, and enhanced durability, making them ideal for a variety of clothing items, from casual wear to formal attire. In addition to its use in apparel, semi-dull filament is also used in the production of home textiles, such as curtains, upholstery, and bed linens, where its aesthetic properties contribute to the overall look and feel of the finished product. Semi-dull staple fiber, on the other hand, is a short fiber that is used in the production of spun yarns. These yarns are then used to create a wide range of textile products, including knitted and woven fabrics. The semi-dull finish of the staple fiber provides a soft, matte appearance that is highly desirable in many textile applications. The use of semi-dull staple fiber is particularly common in the production of casual and sportswear, where the emphasis is on comfort and functionality. The fibers' ability to provide a soft hand feel and excellent moisture management properties makes them ideal for activewear and other performance-oriented garments. Additionally, semi-dull staple fiber is used in the production of nonwoven fabrics, which are used in a variety of applications, including hygiene products, medical textiles, and automotive interiors. The versatility of semi-dull staple fiber allows manufacturers to create products that meet the specific needs of their customers, whether they are looking for high-performance fabrics or aesthetically pleasing textiles. As the demand for high-quality textiles continues to grow, the Global Semi-Dull Chips Market is expected to expand, driven by innovations in material science and the increasing emphasis on sustainable production practices. Manufacturers are continually exploring new ways to enhance the properties of semi-dull chips, such as improving their environmental footprint and developing new formulations that offer enhanced performance characteristics. This ongoing innovation is crucial for meeting the evolving needs of the textile industry and ensuring that semi-dull chips remain a vital component of modern textile manufacturing.

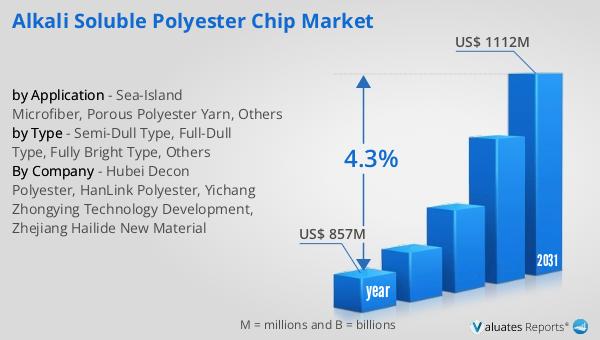

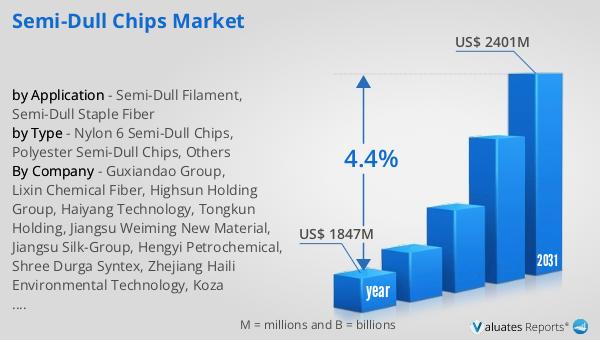

Global Semi-Dull Chips Market Outlook:

In 2024, the global market for Semi-Dull Chips was valued at approximately $1,847 million. Looking ahead, this market is anticipated to grow steadily, reaching an estimated value of $2,401 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.4% over the forecast period. The steady increase in market size reflects the growing demand for semi-dull chips across various applications, driven by the textile industry's need for high-quality, aesthetically pleasing materials. As consumer preferences continue to evolve, manufacturers are increasingly turning to semi-dull chips to enhance the visual appeal and functionality of their products. The market's growth is also supported by advancements in technology and material science, which enable the production of high-performance fibers with enhanced durability and comfort. Additionally, the increasing emphasis on sustainable and eco-friendly production processes is driving innovation in the semi-dull chips market, as manufacturers seek to develop new formulations that offer improved environmental performance. As a result, the global market for semi-dull chips is expected to continue its upward trajectory, providing valuable opportunities for manufacturers and suppliers in the coming years.

| Report Metric | Details |

| Report Name | Semi-Dull Chips Market |

| Accounted market size in year | US$ 1847 million |

| Forecasted market size in 2031 | US$ 2401 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Guxiandao Group, Lixin Chemical Fiber, Highsun Holding Group, Haiyang Technology, Tongkun Holding, Jiangsu Weiming New Material, Jiangsu Silk-Group, Hengyi Petrochemical, Shree Durga Syntex, Zhejiang Haili Environmental Technology, Koza Polyester, Amerex Hubei Decon Polyester, Colossustex, Hengli Group, Libolon, Novara International |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |