What is Global Automatic Gate Lock Market?

The Global Automatic Gate Lock Market is a rapidly evolving sector that focuses on the development and distribution of locking mechanisms designed for automated gates. These locks are integral to enhancing security and convenience for both residential and commercial properties. Automatic gate locks are engineered to work seamlessly with various types of gates, including sliding, swinging, and folding gates, providing a secure and efficient locking solution. The market is driven by the increasing demand for enhanced security systems, technological advancements, and the growing trend of smart homes and buildings. Automatic gate locks offer numerous benefits, such as remote access control, integration with security systems, and ease of use, making them a popular choice among consumers. As urbanization and industrialization continue to rise, the need for secure and automated access control solutions is expected to grow, further propelling the market. The market is characterized by a diverse range of products, catering to different needs and preferences, from basic locking mechanisms to advanced smart locks with biometric and wireless capabilities. This diversity ensures that there is a suitable solution for every application, whether it be for a small residential gate or a large industrial complex.

Single Swing Door, Double Swing Door in the Global Automatic Gate Lock Market:

In the realm of the Global Automatic Gate Lock Market, Single Swing Door and Double Swing Door systems represent significant segments, each with unique features and applications. Single Swing Doors are designed to open in one direction, either inward or outward, and are commonly used in residential settings due to their simplicity and space efficiency. These doors are often equipped with automatic gate locks that provide secure access control, allowing homeowners to manage entry and exit with ease. The locks used in Single Swing Doors are typically robust and designed to withstand various environmental conditions, ensuring long-term reliability and security. On the other hand, Double Swing Doors consist of two panels that swing open from the center, offering a wider opening and a more grandiose entrance. These doors are frequently found in commercial and industrial settings where larger access points are necessary. The automatic gate locks for Double Swing Doors are engineered to handle the increased weight and size of the doors, providing a secure and efficient locking mechanism. Both Single and Double Swing Doors benefit from the integration of smart technologies, such as remote control access, biometric authentication, and integration with security systems, enhancing their functionality and appeal. The choice between Single and Double Swing Doors often depends on the specific requirements of the property, including space availability, aesthetic preferences, and security needs. As the demand for automated and secure access solutions continues to rise, the market for Single and Double Swing Doors is expected to grow, driven by advancements in technology and the increasing emphasis on security and convenience. Manufacturers in the Global Automatic Gate Lock Market are continually innovating to develop more advanced and user-friendly locking solutions, catering to the diverse needs of consumers across different sectors. This innovation is crucial in maintaining competitiveness and meeting the evolving demands of the market. The integration of smart technologies into automatic gate locks is a key trend, enabling users to control and monitor access remotely, enhancing security and convenience. As a result, both Single and Double Swing Doors are becoming increasingly popular in modern architectural designs, offering a blend of functionality, security, and aesthetic appeal. The Global Automatic Gate Lock Market is poised for significant growth, with Single and Double Swing Doors playing a pivotal role in shaping the future of automated access control solutions.

Household, Commercial, Other in the Global Automatic Gate Lock Market:

The usage of Global Automatic Gate Lock Market products spans across various areas, including household, commercial, and other sectors, each with distinct requirements and applications. In households, automatic gate locks are primarily used to enhance security and convenience for homeowners. These locks provide a reliable and efficient way to control access to residential properties, allowing homeowners to manage entry and exit with ease. The integration of smart technologies, such as remote access control and biometric authentication, further enhances the functionality of automatic gate locks in residential settings. Homeowners can monitor and control access to their properties from anywhere, providing peace of mind and added security. In commercial settings, automatic gate locks are essential for managing access to business premises, ensuring the safety and security of employees, customers, and assets. These locks are often integrated with advanced security systems, providing a comprehensive access control solution that can be tailored to the specific needs of the business. The ability to control and monitor access remotely is particularly beneficial for businesses with multiple locations, allowing for centralized management of security systems. In addition to households and commercial settings, automatic gate locks are also used in other areas, such as industrial facilities, educational institutions, and public spaces. In industrial facilities, automatic gate locks are crucial for controlling access to sensitive areas, ensuring the safety and security of personnel and equipment. Educational institutions use automatic gate locks to manage access to school premises, enhancing the safety of students and staff. Public spaces, such as parks and recreational areas, also benefit from the use of automatic gate locks, providing a secure and controlled environment for visitors. The versatility and adaptability of automatic gate locks make them suitable for a wide range of applications, catering to the diverse needs of different sectors. As the demand for secure and automated access control solutions continues to grow, the Global Automatic Gate Lock Market is expected to expand, driven by advancements in technology and the increasing emphasis on security and convenience. Manufacturers are continually innovating to develop more advanced and user-friendly locking solutions, ensuring that there is a suitable product for every application. The integration of smart technologies into automatic gate locks is a key trend, enabling users to control and monitor access remotely, enhancing security and convenience. As a result, automatic gate locks are becoming increasingly popular in modern architectural designs, offering a blend of functionality, security, and aesthetic appeal. The Global Automatic Gate Lock Market is poised for significant growth, with household, commercial, and other sectors playing a pivotal role in shaping the future of automated access control solutions.

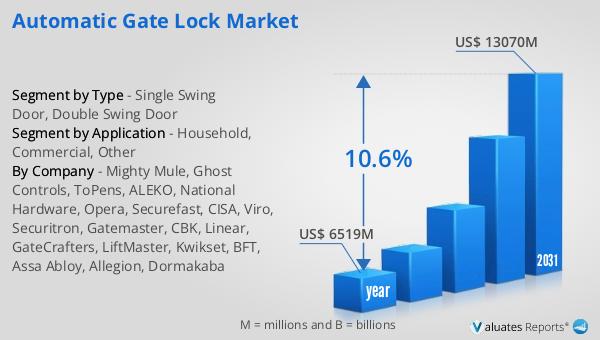

Global Automatic Gate Lock Market Outlook:

The global market for Automatic Gate Locks is on a promising trajectory, with significant growth anticipated over the coming years. In 2024, the market was valued at approximately $6,519 million, reflecting the increasing demand for secure and automated access solutions across various sectors. This demand is driven by the growing emphasis on security and convenience, as well as advancements in technology that have made automatic gate locks more accessible and user-friendly. By 2031, the market is projected to reach a revised size of $13,070 million, indicating a robust compound annual growth rate (CAGR) of 10.6% during the forecast period. This growth is expected to be fueled by the rising adoption of smart technologies, such as remote access control and biometric authentication, which enhance the functionality and appeal of automatic gate locks. As urbanization and industrialization continue to rise, the need for secure and automated access control solutions is expected to grow, further propelling the market. The Global Automatic Gate Lock Market is characterized by a diverse range of products, catering to different needs and preferences, from basic locking mechanisms to advanced smart locks with biometric and wireless capabilities. This diversity ensures that there is a suitable solution for every application, whether it be for a small residential gate or a large industrial complex. As the market continues to evolve, manufacturers are expected to focus on innovation and the development of more advanced and user-friendly locking solutions, ensuring that they remain competitive and meet the evolving demands of consumers. The future of the Global Automatic Gate Lock Market looks promising, with significant growth opportunities and advancements in technology paving the way for a more secure and convenient world.

| Report Metric | Details |

| Report Name | Automatic Gate Lock Market |

| Accounted market size in year | US$ 6519 million |

| Forecasted market size in 2031 | US$ 13070 million |

| CAGR | 10.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Mighty Mule, Ghost Controls, ToPens, ALEKO, National Hardware, Opera, Securefast, CISA, Viro, Securitron, Gatemaster, CBK, Linear, GateCrafters, LiftMaster, Kwikset, BFT, Assa Abloy, Allegion, Dormakaba |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |