What is Global Hard Alloy Valve Core Market?

The Global Hard Alloy Valve Core Market is a specialized segment within the broader valve industry, focusing on the production and distribution of valve cores made from hard alloys. These valve cores are crucial components in various industrial applications due to their durability, resistance to wear and corrosion, and ability to withstand high pressure and temperature conditions. Hard alloy valve cores are typically used in industries where the operational environment is harsh, such as oil and gas, chemical processing, power generation, and metallurgy. The market for these products is driven by the increasing demand for reliable and efficient valve systems that can enhance operational efficiency and safety. As industries continue to expand and modernize, the need for advanced valve technologies, including hard alloy valve cores, is expected to grow. This market is characterized by technological advancements, with manufacturers focusing on developing innovative solutions to meet the evolving needs of their customers. The global reach of this market is significant, with key players operating in various regions to cater to the diverse requirements of different industries. Overall, the Global Hard Alloy Valve Core Market plays a vital role in supporting industrial operations by providing high-quality, durable valve components.

Rotating Type, Translational Type in the Global Hard Alloy Valve Core Market:

In the Global Hard Alloy Valve Core Market, two primary types of valve cores are prevalent: Rotating Type and Translational Type. The Rotating Type valve core is designed to control the flow of fluids by rotating within the valve body. This type of valve core is commonly used in applications where precise control over fluid flow is required. The rotational movement allows for smooth and gradual changes in flow rate, making it ideal for processes that demand high accuracy and reliability. These valve cores are often employed in industries such as oil and gas, where the ability to finely tune the flow of fluids is crucial for maintaining operational efficiency and safety. On the other hand, the Translational Type valve core operates by moving linearly within the valve body. This type of valve core is typically used in applications where quick and decisive control over fluid flow is necessary. The linear movement allows for rapid opening and closing of the valve, making it suitable for processes that require fast response times. Translational Type valve cores are commonly found in industries such as chemical processing and power generation, where the ability to quickly adjust flow rates is essential for maintaining process stability and preventing system disruptions. Both types of valve cores are made from hard alloys, which provide the necessary strength and durability to withstand the demanding conditions of industrial environments. The choice between Rotating Type and Translational Type valve cores depends on the specific requirements of the application, including factors such as flow control precision, response time, and environmental conditions. Manufacturers in the Global Hard Alloy Valve Core Market are continually innovating to improve the performance and reliability of these products, ensuring they meet the evolving needs of their customers. As industries continue to advance and modernize, the demand for high-quality valve cores that can deliver exceptional performance in challenging conditions is expected to grow. This ongoing innovation and development within the market highlight the importance of hard alloy valve cores in supporting industrial operations across various sectors.

Oil and Gas, Chemical Industry, Power Industry, Metallurgical Industry, Others in the Global Hard Alloy Valve Core Market:

The Global Hard Alloy Valve Core Market finds extensive usage across several key industries, including Oil and Gas, Chemical Industry, Power Industry, Metallurgical Industry, and others. In the Oil and Gas sector, hard alloy valve cores are essential for controlling the flow of crude oil, natural gas, and other fluids during extraction, transportation, and refining processes. The harsh conditions of oil and gas operations, such as high pressure, extreme temperatures, and corrosive environments, necessitate the use of durable and reliable valve components. Hard alloy valve cores provide the necessary strength and resistance to wear and corrosion, ensuring safe and efficient operations. In the Chemical Industry, these valve cores are used to regulate the flow of various chemicals and compounds during production and processing. The ability to withstand aggressive chemical environments and maintain precise flow control is critical for ensuring product quality and process safety. Hard alloy valve cores are designed to meet these demands, offering exceptional performance and longevity. The Power Industry also relies on hard alloy valve cores for controlling the flow of steam, water, and other fluids in power plants. The high-pressure and high-temperature conditions of power generation require valve components that can withstand significant stress and maintain reliable operation. Hard alloy valve cores provide the necessary durability and performance to support efficient power generation. In the Metallurgical Industry, these valve cores are used in processes such as smelting and refining, where they control the flow of molten metals and other materials. The extreme temperatures and abrasive conditions of metallurgical operations demand valve components that can endure harsh environments and maintain precise control. Hard alloy valve cores are well-suited for these applications, offering the strength and resilience needed to support metallurgical processes. Beyond these industries, hard alloy valve cores are also used in various other applications where durability, reliability, and precise flow control are essential. The versatility and performance of these valve cores make them a valuable component in a wide range of industrial operations. As industries continue to evolve and face new challenges, the demand for high-quality valve components that can deliver exceptional performance in demanding conditions is expected to grow. The Global Hard Alloy Valve Core Market plays a crucial role in supporting these industries by providing advanced valve solutions that enhance operational efficiency and safety.

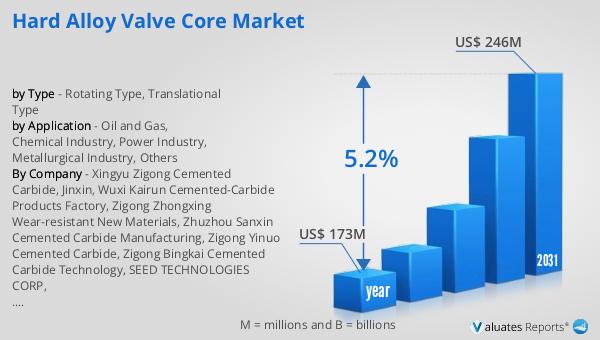

Global Hard Alloy Valve Core Market Outlook:

The global market for Hard Alloy Valve Core was valued at $173 million in 2024 and is anticipated to expand to a revised size of $246 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.2% over the forecast period. This growth trajectory underscores the increasing demand for hard alloy valve cores across various industries, driven by the need for durable and reliable valve components that can withstand harsh operational conditions. The market's expansion is fueled by technological advancements and innovations in valve core design and manufacturing, which enhance performance and extend the lifespan of these critical components. As industries such as oil and gas, chemical processing, power generation, and metallurgy continue to grow and modernize, the demand for high-quality valve cores that can deliver exceptional performance in challenging environments is expected to rise. The projected growth of the Global Hard Alloy Valve Core Market highlights the importance of these components in supporting industrial operations and ensuring the safe and efficient flow of fluids in various applications. Manufacturers in this market are focused on developing innovative solutions to meet the evolving needs of their customers, ensuring that they remain competitive in a rapidly changing industrial landscape. The market's growth prospects are promising, reflecting the ongoing demand for advanced valve technologies that can enhance operational efficiency and safety across a wide range of industries.

| Report Metric | Details |

| Report Name | Hard Alloy Valve Core Market |

| Accounted market size in year | US$ 173 million |

| Forecasted market size in 2031 | US$ 246 million |

| CAGR | 5.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Xingyu Zigong Cemented Carbide, Jinxin, Wuxi Kairun Cemented-Carbide Products Factory, Zigong Zhongxing Wear-resistant New Materials, Zhuzhou Sanxin Cemented Carbide Manufacturing, Zigong Yinuo Cemented Carbide, Zigong Bingkai Cemented Carbide Technology, SEED TECHNOLOGIES CORP, Zhuzhou Zonco Sinotech Wear-resistant Material |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |