What is Global Power Catamaran Market?

The Global Power Catamaran Market is a dynamic and evolving segment within the broader maritime industry, characterized by its focus on multi-hulled vessels powered by engines. These vessels, known as power catamarans, are renowned for their stability, speed, and spaciousness, making them a popular choice for various maritime activities. Unlike traditional monohull boats, catamarans have two parallel hulls, which provide enhanced stability and reduce the likelihood of capsizing. This design also allows for more deck space and greater comfort, making them ideal for leisure and commercial purposes. The market for power catamarans is driven by increasing demand for recreational boating, tourism, and maritime transport. Technological advancements in boat design and propulsion systems have further fueled this growth, enabling manufacturers to offer more efficient and environmentally friendly options. The market is also influenced by regional preferences, with different areas showing varying levels of adoption based on local maritime culture and economic conditions. Overall, the Global Power Catamaran Market represents a significant and growing segment of the maritime industry, offering numerous opportunities for innovation and expansion.

Electric Catamaran, Hybrid Catamaran in the Global Power Catamaran Market:

Electric catamarans and hybrid catamarans are two innovative segments within the Global Power Catamaran Market that are gaining traction due to their environmental benefits and operational efficiencies. Electric catamarans are powered entirely by electric motors, which are typically driven by batteries. These vessels are celebrated for their zero-emission capabilities, making them an attractive option for environmentally conscious consumers and operators. The absence of traditional fuel engines means that electric catamarans operate quietly, reducing noise pollution and enhancing the experience for passengers and marine life alike. The development of electric catamarans is closely tied to advancements in battery technology, with improvements in energy density and charging infrastructure playing a crucial role in their adoption. On the other hand, hybrid catamarans combine traditional internal combustion engines with electric propulsion systems. This dual approach allows operators to switch between power sources depending on the operational requirements, such as using electric power for short distances or in environmentally sensitive areas and relying on combustion engines for longer journeys. Hybrid catamarans offer a balance between performance and sustainability, providing flexibility and reducing fuel consumption. The integration of renewable energy sources, such as solar panels, further enhances the efficiency of hybrid catamarans, making them a viable option for a wide range of applications. Both electric and hybrid catamarans are part of a broader trend towards sustainable maritime transport, driven by regulatory pressures and consumer demand for greener alternatives. As the technology continues to evolve, these vessels are expected to play an increasingly important role in the Global Power Catamaran Market, offering a sustainable and efficient solution for various maritime activities.

Passenger Transport, Cruising, Others in the Global Power Catamaran Market:

The Global Power Catamaran Market finds its application in several key areas, including passenger transport, cruising, and other specialized uses. In passenger transport, power catamarans are utilized for ferry services, offering a reliable and efficient means of moving people across water bodies. Their stability and spaciousness make them ideal for carrying large numbers of passengers, while their speed ensures timely service. In regions with extensive waterways, such as coastal cities or island nations, power catamarans serve as a vital component of the public transport infrastructure, providing an alternative to road and rail networks. In the cruising sector, power catamarans are favored for their comfort and luxury, offering a unique experience for leisure travelers. These vessels are often equipped with amenities such as cabins, dining areas, and entertainment facilities, making them a popular choice for charter services and private ownership. The cruising market is driven by the growing demand for experiential travel, with consumers seeking unique and memorable experiences on the water. Beyond passenger transport and cruising, power catamarans are also used in various other applications, such as research and exploration, where their stability and range make them suitable for scientific missions and environmental monitoring. Additionally, they are employed in the tourism industry for activities such as whale watching and snorkeling tours, where their maneuverability and shallow draft allow for close encounters with marine life. The versatility of power catamarans makes them a valuable asset in the maritime industry, catering to a diverse range of needs and preferences. As the market continues to grow, the usage of power catamarans is expected to expand further, driven by technological advancements and changing consumer demands.

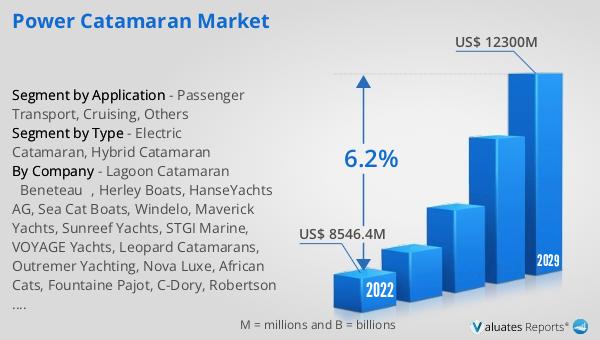

Global Power Catamaran Market Outlook:

In 2024, the global market for power catamarans was valued at approximately $9,056 million. Looking ahead, this market is anticipated to grow significantly, reaching an estimated size of $13,720 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.2% over the forecast period. This upward trend is indicative of the increasing demand for power catamarans across various sectors, including leisure, tourism, and transportation. The market's expansion is fueled by several factors, including technological advancements in boat design and propulsion systems, as well as a growing emphasis on sustainability and environmental responsibility. As consumers and operators seek more efficient and eco-friendly options, the adoption of electric and hybrid catamarans is expected to rise, contributing to the overall market growth. Additionally, the versatility and adaptability of power catamarans make them an attractive option for a wide range of applications, further driving their popularity. As the market continues to evolve, stakeholders in the industry are likely to explore new opportunities for innovation and expansion, capitalizing on the growing demand for power catamarans worldwide.

| Report Metric | Details |

| Report Name | Power Catamaran Market |

| Accounted market size in year | US$ 9056 million |

| Forecasted market size in 2031 | US$ 13720 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Lagoon Catamaran (Beneteau), Herley Boats, HanseYachts AG, Sea Cat Boats, Windelo, Maverick Yachts, Sunreef Yachts, STGI Marine, VOYAGE Yachts, Leopard Catamarans, Outremer Yachting, Nova Luxe, African Cats, Fountaine Pajot, C-Dory, Robertson and Caine, Seawind Group Holdings Pty Ltd, Aquila Power Catamarans, E-catamaran |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |