What is Global Compound Extruder Market?

The Global Compound Extruder Market is a dynamic and evolving sector that plays a crucial role in various industries by providing essential machinery for the production of compounded materials. Compound extruders are specialized machines used to mix and shape materials, primarily polymers, into desired forms. These machines are integral in the manufacturing processes of numerous products, ranging from plastic goods to food items. The market for compound extruders is driven by the increasing demand for high-performance materials and the need for efficient production processes. As industries continue to innovate and develop new materials, the demand for advanced extruder technology grows. The market is characterized by a diverse range of extruder types, each designed to meet specific production needs. With advancements in technology, compound extruders are becoming more efficient, versatile, and capable of handling a wider variety of materials. This evolution is crucial for industries aiming to enhance product quality and production efficiency. The global reach of this market underscores its importance, as manufacturers worldwide seek to optimize their production capabilities and meet the growing demands of their respective industries. As such, the Global Compound Extruder Market is poised for continued growth and innovation.

Twin Screw Extruder, Single Screw Extruder in the Global Compound Extruder Market:

In the realm of the Global Compound Extruder Market, two primary types of extruders stand out: Twin Screw Extruders and Single Screw Extruders. Each type has its unique features and applications, catering to different industrial needs. Twin Screw Extruders are renowned for their versatility and efficiency in processing a wide range of materials. They consist of two intermeshing screws that rotate within a barrel, providing excellent mixing capabilities and superior control over the extrusion process. This design allows for precise temperature control and efficient heat transfer, making them ideal for processing heat-sensitive materials. Twin Screw Extruders are widely used in industries such as plastics, food, and pharmaceuticals, where precise control over the mixing and shaping of materials is crucial. Their ability to handle complex formulations and achieve high throughput rates makes them a preferred choice for manufacturers seeking to optimize production efficiency and product quality. On the other hand, Single Screw Extruders are simpler in design, featuring a single rotating screw within a barrel. They are widely used for straightforward extrusion processes where complex mixing is not required. Single Screw Extruders are particularly effective for processing materials with consistent properties, such as certain types of plastics and rubber. They are valued for their cost-effectiveness and ease of operation, making them a popular choice for small to medium-sized production facilities. While they may not offer the same level of mixing capabilities as Twin Screw Extruders, Single Screw Extruders excel in applications where simplicity and reliability are paramount. In the Global Compound Extruder Market, the choice between Twin Screw and Single Screw Extruders often depends on the specific requirements of the production process. Manufacturers must consider factors such as material properties, desired output, and production scale when selecting the appropriate extruder type. As technology continues to advance, both Twin Screw and Single Screw Extruders are evolving to meet the changing demands of the market. Innovations in screw design, materials, and control systems are enhancing the performance and versatility of these machines, enabling manufacturers to achieve higher levels of efficiency and product quality. The Global Compound Extruder Market is thus characterized by a dynamic interplay between these two types of extruders, each contributing to the advancement of industrial production processes. As industries continue to evolve and demand more sophisticated materials and products, the role of Twin Screw and Single Screw Extruders in the Global Compound Extruder Market will remain pivotal.

Cable Compounds, Engineering Plastics, Food and Feed, Others in the Global Compound Extruder Market:

The Global Compound Extruder Market finds extensive applications across various sectors, including Cable Compounds, Engineering Plastics, Food and Feed, and others. In the cable industry, compound extruders are essential for producing cable compounds that provide insulation and protection for electrical wires. These compounds are critical for ensuring the safety and reliability of electrical systems, and the precision offered by compound extruders is vital for achieving the desired material properties. The ability to control the mixing and shaping of materials allows manufacturers to produce high-quality cable compounds that meet stringent industry standards. In the realm of Engineering Plastics, compound extruders play a crucial role in the production of high-performance materials used in automotive, aerospace, and consumer electronics industries. These plastics require precise formulation and processing to achieve the desired mechanical and thermal properties. Compound extruders enable manufacturers to create customized plastic compounds that meet specific performance criteria, enhancing the functionality and durability of the final products. In the Food and Feed industry, compound extruders are used to produce a wide range of products, from pet food to breakfast cereals. The ability to control the extrusion process allows manufacturers to create products with specific textures, shapes, and nutritional profiles. This versatility is essential for meeting the diverse demands of consumers and ensuring product consistency and quality. Additionally, compound extruders are used in the production of feed for livestock, where precise formulation is crucial for ensuring the health and productivity of animals. Beyond these specific applications, the Global Compound Extruder Market also serves other industries, such as pharmaceuticals and construction. In the pharmaceutical industry, compound extruders are used to produce drug formulations with precise dosage and release characteristics. In the construction industry, they are used to produce materials such as sealants and adhesives, where precise mixing and shaping are essential for achieving the desired performance. The versatility and efficiency of compound extruders make them indispensable tools in these industries, enabling manufacturers to meet the evolving demands of their markets. As industries continue to innovate and develop new products, the role of the Global Compound Extruder Market in facilitating these advancements will remain critical.

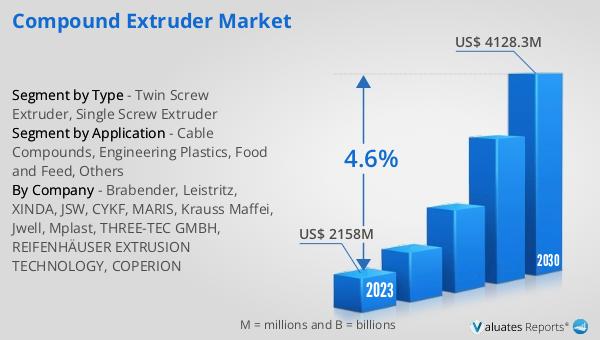

Global Compound Extruder Market Outlook:

The global market for Compound Extruders was valued at approximately $3,282 million in 2024, and it is anticipated to grow to a revised size of around $4,477 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.6% over the forecast period. This upward trend highlights the increasing demand for compound extruders across various industries, driven by the need for efficient and versatile production processes. As industries continue to evolve and innovate, the demand for advanced extruder technology is expected to rise, contributing to the market's growth. The projected growth of the Compound Extruder Market underscores the importance of these machines in modern manufacturing processes. With their ability to handle a wide range of materials and applications, compound extruders are becoming increasingly essential for industries seeking to enhance product quality and production efficiency. As the market continues to expand, manufacturers are likely to invest in advanced extruder technology to meet the growing demands of their respective industries. This growth is indicative of the critical role that compound extruders play in facilitating industrial advancements and meeting the evolving needs of the global market.

| Report Metric | Details |

| Report Name | Compound Extruder Market |

| Accounted market size in year | US$ 3282 million |

| Forecasted market size in 2031 | US$ 4477 million |

| CAGR | 4.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Brabender, Leistritz, XINDA, JSW, CYKF, MARIS, Krauss Maffei, Jwell, Mplast, THREE-TEC GMBH, REIFENHÄUSER EXTRUSION TECHNOLOGY, COPERION |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |