What is Global Automatic Brick Making Machine Market?

The Global Automatic Brick Making Machine Market refers to the industry focused on the production and distribution of machines that automate the brick-making process. These machines are designed to produce bricks efficiently and consistently, reducing the need for manual labor and increasing production speed. The market encompasses a variety of machines, including fully automatic and semi-automatic models, each catering to different production needs and scales. The demand for automatic brick making machines is driven by the growing construction industry, which requires a steady supply of bricks for building infrastructure. Additionally, the push for sustainable and efficient building practices has led to increased interest in these machines, as they often incorporate advanced technologies that minimize waste and energy consumption. The market is characterized by a diverse range of manufacturers and suppliers, each offering machines with varying capabilities and features to meet the specific needs of their customers. As urbanization and industrialization continue to rise globally, the demand for automatic brick making machines is expected to grow, making this market a vital component of the construction industry.

Fully Automatic Brick Making Machine, Semi-automatic Brick Making Machine in the Global Automatic Brick Making Machine Market:

Fully Automatic Brick Making Machines are at the forefront of innovation in the Global Automatic Brick Making Machine Market. These machines are designed to operate with minimal human intervention, offering a seamless and efficient brick production process. They are equipped with advanced technologies such as programmable logic controllers (PLCs) and human-machine interfaces (HMIs), which allow for precise control over the production process. This level of automation ensures consistent quality and high production rates, making them ideal for large-scale brick manufacturing operations. Fully automatic machines can handle various stages of brick production, including mixing raw materials, molding, drying, and firing, all in a streamlined process. This not only reduces labor costs but also minimizes the potential for human error, resulting in a more reliable and efficient production line. On the other hand, Semi-automatic Brick Making Machines offer a balance between automation and manual operation. While they require some level of human intervention, these machines still provide significant improvements in efficiency and productivity compared to traditional manual methods. Semi-automatic machines are often more affordable than their fully automatic counterparts, making them an attractive option for small to medium-sized enterprises or those with budget constraints. They typically involve manual loading of raw materials and some manual control over the production process, but they still automate key stages such as molding and pressing. This allows manufacturers to increase their output without the need for a fully automated system. Both types of machines play a crucial role in the Global Automatic Brick Making Machine Market, catering to different segments of the industry based on production needs and budget considerations. The choice between fully automatic and semi-automatic machines depends largely on the scale of production, available budget, and specific operational requirements. As technology continues to advance, both types of machines are expected to incorporate more sophisticated features, further enhancing their efficiency and appeal to manufacturers worldwide.

Building Construction, Industrial, Others in the Global Automatic Brick Making Machine Market:

The usage of Global Automatic Brick Making Machines spans across various sectors, with significant applications in building construction, industrial, and other areas. In the realm of building construction, these machines are indispensable due to their ability to produce high-quality bricks at a rapid pace. The construction industry relies heavily on bricks as a fundamental building material, and the efficiency of automatic brick making machines ensures a steady supply to meet the demands of large-scale projects. These machines enable construction companies to maintain tight schedules and budgets by providing a reliable source of bricks without the delays associated with manual production methods. In industrial applications, automatic brick making machines are utilized for the production of specialized bricks used in various industrial processes. These may include refractory bricks for high-temperature applications, insulating bricks for thermal management, and other specialized types that require precise manufacturing techniques. The automation provided by these machines ensures that industrial bricks meet stringent quality standards, which is crucial for their performance in demanding environments. Additionally, the ability to customize brick shapes and sizes allows industries to tailor their products to specific needs, enhancing their versatility and application range. Beyond construction and industrial uses, automatic brick making machines find applications in other areas such as landscaping, road construction, and infrastructure development. In landscaping, bricks are often used for creating aesthetically pleasing pathways, garden walls, and other decorative elements. The precision and consistency offered by automatic machines ensure that these bricks meet the desired aesthetic and functional requirements. In road construction and infrastructure projects, bricks are used for paving, retaining walls, and other structural components. The durability and uniformity of bricks produced by automatic machines make them ideal for these applications, where long-lasting performance is essential. Overall, the versatility and efficiency of Global Automatic Brick Making Machines make them a valuable asset across various sectors, contributing to the advancement of construction and industrial practices worldwide.

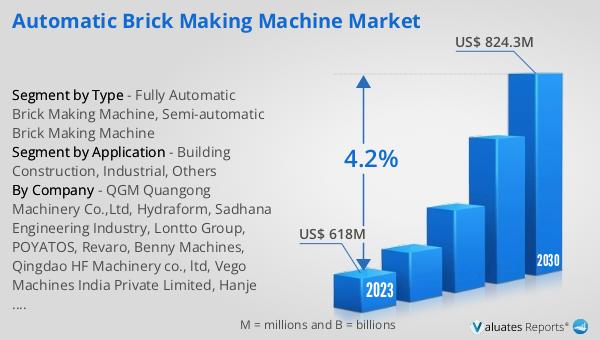

Global Automatic Brick Making Machine Market Outlook:

The global market for Automatic Brick Making Machines was valued at approximately $668 million in 2024. This market is anticipated to expand significantly, reaching an estimated size of $888 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.2% over the forecast period. This upward trend is indicative of the increasing demand for efficient and automated solutions in the brick manufacturing industry. The growth is driven by several factors, including the rising construction activities worldwide, the need for sustainable building practices, and the technological advancements in brick making machinery. As urbanization continues to accelerate, particularly in developing regions, the demand for bricks is expected to rise, further fueling the market for automatic brick making machines. Additionally, the emphasis on reducing labor costs and improving production efficiency is prompting manufacturers to invest in automated solutions. The market's expansion is also supported by the growing awareness of the environmental benefits associated with automated brick production, such as reduced waste and energy consumption. As a result, the Global Automatic Brick Making Machine Market is poised for steady growth, offering numerous opportunities for manufacturers and suppliers to capitalize on the increasing demand for advanced brick making technologies.

| Report Metric | Details |

| Report Name | Automatic Brick Making Machine Market |

| Accounted market size in year | US$ 668 million |

| Forecasted market size in 2031 | US$ 888 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | QGM Quangong Machinery Co.,Ltd, Hydraform, Sadhana Engineering Industry, Lontto Group, POYATOS, Revaro, Benny Machines, Qingdao HF Machinery co., ltd, Vego Machines India Private Limited, Hanje Hydrotech, Vishwakarma Creative Engineering Pvt. Ltd, Aimix Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |