What is Global Modular Sterile Isolator Market?

The Global Modular Sterile Isolator Market is a specialized segment within the broader healthcare and pharmaceutical industries, focusing on the provision of controlled environments for handling sensitive materials. These isolators are designed to maintain sterility and prevent contamination during various processes, such as drug manufacturing, laboratory research, and clinical applications. They are modular, meaning they can be customized and configured to meet specific needs, making them versatile for different settings. The market for these isolators is driven by the increasing demand for sterile environments in healthcare and pharmaceutical sectors, where maintaining product integrity and safety is paramount. As regulations around sterility and contamination control become more stringent, the need for advanced isolator solutions continues to grow. This market is characterized by technological advancements, with manufacturers continually innovating to improve the efficiency, reliability, and user-friendliness of these systems. The global reach of this market is expanding as more regions recognize the importance of maintaining high standards of sterility in medical and pharmaceutical operations. Overall, the Global Modular Sterile Isolator Market plays a crucial role in ensuring the safety and efficacy of products and processes in critical sectors.

Class II, Class III, Others in the Global Modular Sterile Isolator Market:

In the Global Modular Sterile Isolator Market, products are often categorized based on their class, which determines their specific applications and capabilities. Class II isolators are designed to provide a controlled environment for handling hazardous materials, offering protection to both the product and the operator. These isolators are commonly used in laboratories and pharmaceutical settings where there is a need to handle potentially dangerous substances safely. They are equipped with advanced filtration systems and airflow mechanisms to ensure that contaminants are effectively removed from the environment. Class III isolators, on the other hand, offer a higher level of containment and are typically used for handling highly hazardous or infectious materials. These isolators are completely sealed and provide a barrier between the operator and the materials being handled. They are often used in research and development settings where the highest level of sterility and containment is required. Other types of isolators in this market include those designed for specific applications, such as aseptic processing or sterile compounding. These isolators are tailored to meet the unique needs of different industries and processes, offering flexibility and adaptability. The choice of isolator class depends on the specific requirements of the application, with considerations for factors such as the level of containment needed, the type of materials being handled, and the regulatory standards that must be met. As the demand for sterile environments continues to grow, manufacturers are developing new and innovative isolator solutions to meet the evolving needs of the market. This includes advancements in materials, design, and technology to enhance the performance and reliability of these systems. The Global Modular Sterile Isolator Market is a dynamic and rapidly evolving sector, with a wide range of products available to meet the diverse needs of its customers.

Hospital, Pharmaceutical, Laboratory, Others in the Global Modular Sterile Isolator Market:

The usage of Global Modular Sterile Isolators spans across various sectors, each with its unique requirements and applications. In hospitals, these isolators are crucial for maintaining sterile environments during surgical procedures and in intensive care units. They help prevent infections and ensure patient safety by providing a controlled environment that minimizes the risk of contamination. In the pharmaceutical industry, modular sterile isolators are essential for the production of drugs and vaccines. They provide a sterile environment for the manufacturing process, ensuring that products are free from contaminants and meet regulatory standards. This is particularly important in the production of sterile injectables and other sensitive pharmaceutical products. Laboratories also rely heavily on modular sterile isolators for research and development activities. These isolators provide a controlled environment for conducting experiments and handling sensitive materials, ensuring the integrity of the research process. They are used in a wide range of laboratory settings, from academic research institutions to commercial R&D facilities. Other sectors that utilize modular sterile isolators include biotechnology, food and beverage, and electronics manufacturing. In biotechnology, these isolators are used for the production of biologics and other sensitive products. In the food and beverage industry, they help maintain hygiene and prevent contamination during the production process. In electronics manufacturing, they provide a controlled environment for the production of sensitive electronic components. Overall, the Global Modular Sterile Isolator Market serves a wide range of industries, each with its unique requirements and applications. The versatility and adaptability of these isolators make them an essential tool for maintaining sterility and ensuring the safety and efficacy of products and processes.

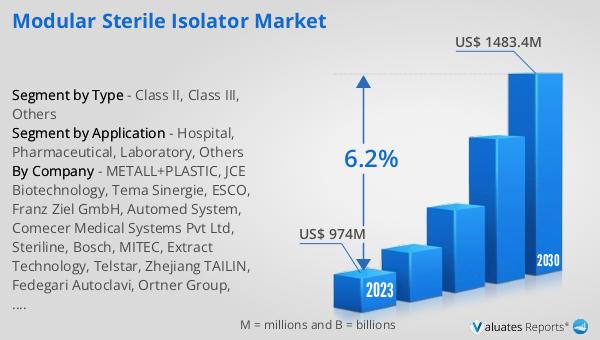

Global Modular Sterile Isolator Market Outlook:

The global market for Modular Sterile Isolators was valued at $1,092 million in 2024, and it is anticipated to grow significantly, reaching an estimated size of $1,654 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.2% over the forecast period. This upward trend is indicative of the increasing demand for sterile environments across various sectors, including healthcare, pharmaceuticals, and biotechnology. The market's expansion is driven by the need for advanced isolator solutions that can meet the stringent regulatory standards for sterility and contamination control. As industries continue to prioritize product safety and efficacy, the demand for modular sterile isolators is expected to rise. This growth is also supported by technological advancements in isolator design and materials, which enhance their performance and reliability. The market's projected growth reflects the critical role that modular sterile isolators play in ensuring the safety and integrity of products and processes in key industries. As the market continues to evolve, manufacturers are likely to focus on developing innovative solutions that address the specific needs of their customers, further driving the market's growth.

| Report Metric | Details |

| Report Name | Modular Sterile Isolator Market |

| Accounted market size in year | US$ 1092 million |

| Forecasted market size in 2031 | US$ 1654 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | METALL+PLASTIC, JCE Biotechnology, Tema Sinergie, ESCO, Franz Ziel GmbH, Automed System, Comecer Medical Systems Pvt Ltd, Steriline, Bosch, MITEC, Extract Technology, Telstar, Zhejiang TAILIN, Fedegari Autoclavi, Ortner Group, Getinge, SHIBUYA CORPORATION, SKAN |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |