What is Global PP Baling Twines Market?

The Global PP Baling Twines Market refers to the worldwide industry focused on the production and distribution of polypropylene (PP) baling twines. These twines are essential in agricultural and industrial applications for binding and securing bales of hay, straw, and other materials. Polypropylene is a popular choice for baling twines due to its durability, resistance to rot and mildew, and ability to withstand various weather conditions. The market for PP baling twines is driven by the increasing demand for efficient and reliable baling solutions in agriculture, where they are used extensively to bundle crops for storage and transport. Additionally, the industrial sector utilizes these twines for packaging and securing goods. The market is characterized by a variety of products that cater to different needs, including variations in strength, thickness, and color. As the global population grows and agricultural practices become more mechanized, the demand for PP baling twines is expected to rise, making it a vital component of the agricultural supply chain. The market is also influenced by environmental considerations, with manufacturers exploring eco-friendly alternatives and recycling options to meet sustainability goals.

Light Duty, Medium Duty, Heavy Duty in the Global PP Baling Twines Market:

In the Global PP Baling Twines Market, products are typically categorized based on their duty levels: Light Duty, Medium Duty, and Heavy Duty. Each category serves specific purposes and is designed to meet varying demands in terms of strength and durability. Light Duty PP baling twines are generally used for applications that require less tensile strength. These are ideal for smaller bales or lighter materials, such as straw or grass. They are cost-effective and suitable for farmers who need to bundle materials that do not exert significant pressure on the twine. Light Duty twines are often used in regions with less demanding agricultural practices or where the climate is mild, reducing the risk of twine degradation. Medium Duty PP baling twines offer a balance between strength and flexibility. They are designed for more robust applications than Light Duty twines and are commonly used for hay baling. These twines provide sufficient strength to handle moderate pressure and are versatile enough to be used in various agricultural settings. Medium Duty twines are popular among farmers who need a reliable solution for bundling crops that are heavier or more voluminous than those suitable for Light Duty twines. They are also favored in areas with moderate weather conditions, where the twine must withstand occasional rain or wind. Heavy Duty PP baling twines are the strongest and most durable option available in the market. They are engineered to handle the most demanding applications, such as baling large, dense bales of hay or other heavy materials. These twines are essential for farmers and industrial users who require maximum strength and reliability. Heavy Duty twines are often used in regions with harsh weather conditions, where the twine must endure extreme temperatures, moisture, and UV exposure. They are also suitable for use with high-capacity baling machines that exert significant force during the baling process. The choice between Light Duty, Medium Duty, and Heavy Duty PP baling twines depends on several factors, including the type of material being baled, the size and weight of the bales, and the environmental conditions in which the twine will be used. Farmers and industrial users must carefully consider these factors to select the appropriate twine for their needs. Additionally, manufacturers continue to innovate and improve the quality of PP baling twines, offering products with enhanced UV resistance, increased tensile strength, and improved knotting capabilities. This ongoing development ensures that the Global PP Baling Twines Market can meet the evolving demands of its diverse customer base.

Row Crop, Cash Crop in the Global PP Baling Twines Market:

The usage of Global PP Baling Twines Market products in row crop and cash crop farming is significant, as these twines play a crucial role in the efficient handling and storage of agricultural produce. In row crop farming, which involves the cultivation of crops like corn, soybeans, and wheat, PP baling twines are used to bundle and secure the harvested crops. These twines help in organizing the crops into manageable bales, making it easier for farmers to transport and store them. The durability and strength of PP baling twines ensure that the bales remain intact during handling, reducing the risk of crop loss or damage. In cash crop farming, where the focus is on growing crops for sale rather than personal consumption, the use of PP baling twines is equally important. Cash crops such as cotton, tobacco, and sugarcane require efficient bundling solutions to maintain their quality and market value. PP baling twines provide the necessary support to secure these crops, ensuring they reach the market in optimal condition. The versatility of PP baling twines allows them to be used with various types of baling equipment, from manual balers to advanced mechanized systems. This adaptability makes them a preferred choice for farmers looking to optimize their operations and improve productivity. Moreover, the use of PP baling twines in both row crop and cash crop farming contributes to the overall efficiency of the agricultural supply chain. By facilitating the easy handling and transportation of crops, these twines help reduce labor costs and minimize the time required for post-harvest processing. This efficiency is particularly important in cash crop farming, where timely delivery to the market can significantly impact profitability. As the demand for agricultural produce continues to grow, the role of PP baling twines in supporting sustainable and efficient farming practices becomes increasingly vital.

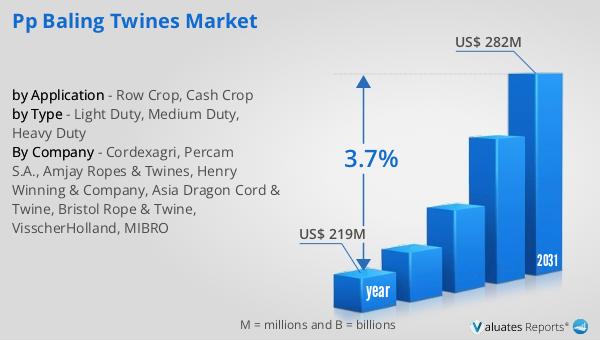

Global PP Baling Twines Market Outlook:

The global market for PP Baling Twines was valued at $219 million in 2024, with projections indicating it will expand to a revised size of $282 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.7% over the forecast period. The steady increase in market size reflects the rising demand for PP baling twines across various sectors, particularly in agriculture and industry. As the agricultural sector continues to evolve with advancements in technology and mechanization, the need for reliable and efficient baling solutions becomes more pronounced. PP baling twines, known for their strength, durability, and resistance to environmental factors, are well-suited to meet these demands. Additionally, the industrial sector's reliance on secure packaging solutions further drives the market's growth. The projected expansion of the PP Baling Twines Market underscores the importance of these products in supporting global agricultural and industrial activities. As manufacturers continue to innovate and improve the quality of PP baling twines, the market is expected to maintain its upward trajectory, providing essential solutions for bundling and securing materials worldwide.

| Report Metric | Details |

| Report Name | PP Baling Twines Market |

| Accounted market size in year | US$ 219 million |

| Forecasted market size in 2031 | US$ 282 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Cordexagri, Percam S.A., Amjay Ropes & Twines, Henry Winning & Company, Asia Dragon Cord & Twine, Bristol Rope & Twine, VisscherHolland, MIBRO |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |