What is Global Polyethylene Surface Protective Film Market?

The Global Polyethylene Surface Protective Film Market is a dynamic and essential segment within the broader protective film industry. These films are primarily used to safeguard surfaces from scratches, dust, and damage during manufacturing, transportation, and installation processes. Polyethylene, a versatile and widely used plastic, forms the base material for these protective films due to its excellent durability, flexibility, and cost-effectiveness. The market is driven by the increasing demand for protective solutions across various industries, including electronics, automotive, construction, and packaging. As industries continue to innovate and produce delicate and high-value products, the need for reliable surface protection becomes more critical. Polyethylene surface protective films are available in various thicknesses and adhesive strengths, catering to different application needs. They are designed to adhere securely to surfaces without leaving residue upon removal, ensuring that the protected items remain pristine. The market's growth is further fueled by advancements in film technology, which enhance the performance and environmental sustainability of these products. As global trade and manufacturing activities expand, the demand for polyethylene surface protective films is expected to rise, making it a vital component in the protection of goods worldwide.

Low-density Polyethylene, Medium-density Polyethylene, High-density Polyethylene in the Global Polyethylene Surface Protective Film Market:

Polyethylene surface protective films are categorized based on the density of the polyethylene used, which significantly influences their properties and applications. Low-density polyethylene (LDPE) films are known for their flexibility and resilience. They are often used in applications where a high degree of stretchability is required, such as in packaging and covering irregularly shaped items. LDPE films provide excellent protection against moisture and are resistant to chemicals, making them suitable for a wide range of protective applications. Their softness and pliability allow them to conform to surfaces easily, providing a snug fit that ensures comprehensive protection. Medium-density polyethylene (MDPE) films strike a balance between the flexibility of LDPE and the strength of high-density polyethylene (HDPE). MDPE films are tougher and more resistant to punctures and tears than LDPE, making them ideal for applications that require a higher level of durability. They are commonly used in the construction industry for protecting surfaces like glass and metal during building projects. MDPE films offer good chemical resistance and are less prone to deformation under stress, ensuring that they maintain their protective qualities over time. High-density polyethylene (HDPE) films are the most robust among the three types. They are characterized by their high tensile strength and resistance to impact and abrasion. HDPE films are often used in demanding environments where maximum protection is required, such as in the automotive and heavy machinery industries. These films provide excellent barrier properties against moisture, dust, and other environmental factors, ensuring that the surfaces they protect remain unscathed. Despite their rigidity, HDPE films can be engineered to offer some degree of flexibility, allowing them to be used in a variety of applications. The choice between LDPE, MDPE, and HDPE films depends on the specific requirements of the application, including the level of protection needed, the nature of the surface being protected, and the environmental conditions to which the film will be exposed. Each type of polyethylene film offers unique advantages, making them indispensable in the global polyethylene surface protective film market.

Injection Molding Products, Electronics, Metal Products, Others in the Global Polyethylene Surface Protective Film Market:

The Global Polyethylene Surface Protective Film Market finds extensive usage across various sectors, each with its unique requirements and challenges. In the realm of injection molding products, these films play a crucial role in maintaining the integrity and appearance of molded items. Injection molding is a process used to produce a wide range of plastic parts, from small components to large panels. During production, handling, and transportation, these parts are susceptible to scratches, dust, and other forms of damage. Polyethylene surface protective films provide a reliable barrier that preserves the quality and finish of these products, ensuring they reach the end-user in perfect condition. In the electronics industry, the demand for polyethylene surface protective films is driven by the need to protect delicate components and devices. Electronics, such as smartphones, tablets, and televisions, have sensitive screens and surfaces that require protection from scratches and smudges. These films are designed to adhere gently to electronic surfaces, providing a protective layer that can be easily removed without leaving residue. This ensures that the devices remain visually appealing and functional, enhancing the consumer experience. Metal products, including stainless steel, aluminum, and other alloys, also benefit significantly from polyethylene surface protective films. These films prevent surface damage during manufacturing, storage, and transportation, preserving the aesthetic and functional qualities of metal products. In industries such as construction and automotive, where metal components are prevalent, the use of protective films is essential to maintain the quality and longevity of the products. Additionally, polyethylene surface protective films are used in various other applications, such as protecting glass surfaces, laminates, and painted surfaces. Their versatility and effectiveness make them a preferred choice for industries seeking to safeguard their products from damage and contamination. As the demand for high-quality, damage-free products continues to grow, the usage of polyethylene surface protective films is expected to expand across different sectors, reinforcing their importance in the global market.

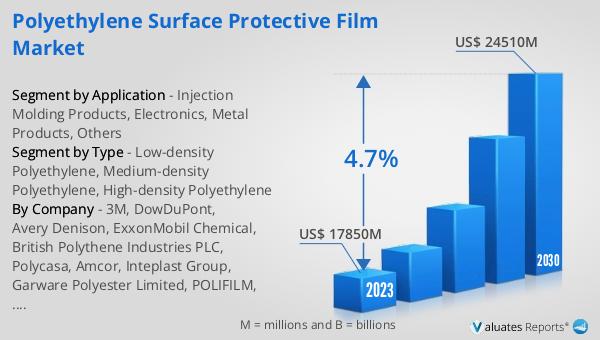

Global Polyethylene Surface Protective Film Market Outlook:

The global market for Polyethylene Surface Protective Film was valued at $19,390 million in 2024 and is anticipated to grow significantly in the coming years. By 2031, the market is projected to reach a revised size of $26,630 million, reflecting a compound annual growth rate (CAGR) of 4.7% during the forecast period. This growth trajectory underscores the increasing demand for protective solutions across various industries. The rising awareness about the benefits of using polyethylene surface protective films, such as their ability to prevent damage and maintain the quality of products, is a key factor driving this market expansion. As industries continue to innovate and produce high-value, delicate products, the need for reliable surface protection becomes more critical. The market's growth is also supported by advancements in film technology, which enhance the performance and environmental sustainability of these products. With the expansion of global trade and manufacturing activities, the demand for polyethylene surface protective films is expected to rise, making it a vital component in the protection of goods worldwide. This positive market outlook highlights the essential role that polyethylene surface protective films play in safeguarding products and ensuring their quality and longevity.

| Report Metric | Details |

| Report Name | Polyethylene Surface Protective Film Market |

| Accounted market size in year | US$ 19390 million |

| Forecasted market size in 2031 | US$ 26630 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | 3M, DowDuPont, Avery Denison, ExxonMobil Chemical, British Polythene Industries PLC, Polycasa, Amcor, Inteplast Group, Garware Polyester Limited, POLIFILM, Nitto Denko Corp., Hi-Bond Tapes Ltd., PPI Adhesive Products, ECHOtape |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |