What is Global Rotator Cuff Repair Suture Anchor Market?

The Global Rotator Cuff Repair Suture Anchor Market is a specialized segment within the broader medical device industry, focusing on products used to repair rotator cuff injuries. The rotator cuff is a group of muscles and tendons that stabilize the shoulder joint, and injuries to this area are common, especially among athletes and older adults. Suture anchors are small devices used to attach tendons to bone during surgical repair of the rotator cuff. These anchors are crucial for ensuring that the tendon heals properly and regains its full function. The market for these devices is driven by factors such as the increasing prevalence of shoulder injuries, advancements in surgical techniques, and the growing aging population. Additionally, the market is characterized by continuous innovation, with manufacturers developing new materials and designs to improve the effectiveness and safety of suture anchors.

Alloy, Bioceramic, Others in the Global Rotator Cuff Repair Suture Anchor Market:

In the Global Rotator Cuff Repair Suture Anchor Market, materials play a significant role in the performance and application of the devices. Alloy-based suture anchors are commonly used due to their strength and durability. These anchors are typically made from metals such as titanium or stainless steel, which provide excellent mechanical properties and biocompatibility. Alloy anchors are particularly favored in situations where high tensile strength is required, and they are less likely to break or deform under stress. However, one downside is that they can sometimes cause imaging artifacts in MRI scans, which can complicate postoperative assessments. Bioceramic suture anchors are another important category, known for their excellent biocompatibility and ability to integrate with bone tissue. These anchors are made from materials such as hydroxyapatite or calcium phosphate, which are similar to the mineral components of bone. This similarity allows bioceramic anchors to promote bone growth and improve the healing process. They are often used in patients who may have allergic reactions to metal or in cases where long-term biocompatibility is a priority. One of the challenges with bioceramic anchors is that they can be more brittle than metal anchors, which may limit their use in certain high-stress applications. Other materials used in suture anchors include bioabsorbable polymers, which are designed to gradually dissolve in the body over time. These anchors are made from materials such as polylactic acid (PLA) or polyglycolic acid (PGA), which are broken down by the body’s natural processes. Bioabsorbable anchors are advantageous because they eliminate the need for a second surgery to remove the anchor and reduce the risk of long-term complications. However, their mechanical strength is generally lower than that of metal or bioceramic anchors, which can be a limitation in some cases. Each type of material used in suture anchors has its own set of advantages and disadvantages, and the choice of material often depends on the specific needs of the patient and the surgeon’s preference. For example, alloy anchors might be chosen for their strength in a young, active patient, while bioceramic anchors might be preferred for their biocompatibility in an older patient with a slower healing process. Bioabsorbable anchors might be selected for patients who are concerned about long-term foreign materials in their body. The ongoing research and development in this field aim to address the limitations of each material and create suture anchors that combine the best properties of strength, biocompatibility, and bioabsorbability.

Hospital, Clinic in the Global Rotator Cuff Repair Suture Anchor Market:

The usage of Global Rotator Cuff Repair Suture Anchor Market products is prevalent in both hospitals and clinics, each setting offering unique advantages and challenges. In hospitals, rotator cuff repair surgeries are often performed in well-equipped operating rooms with access to advanced imaging technologies and a full range of surgical instruments. Hospitals typically have specialized orthopedic surgeons who are experienced in performing complex shoulder surgeries. The availability of comprehensive postoperative care, including physical therapy and rehabilitation services, is another significant advantage of hospital settings. Patients undergoing rotator cuff repair in hospitals can benefit from a multidisciplinary approach to care, which can improve outcomes and reduce the risk of complications. Clinics, on the other hand, offer a more personalized and often more convenient setting for rotator cuff repair surgeries. Many clinics are equipped with the necessary surgical facilities to perform these procedures on an outpatient basis, allowing patients to return home the same day. This can be particularly appealing for patients who prefer to avoid the longer stays and higher costs associated with hospital-based surgeries. Clinics often provide a more intimate and patient-centered environment, which can enhance the overall patient experience. However, clinics may have limitations in terms of the complexity of surgeries they can perform and the range of postoperative services they can offer. In both hospitals and clinics, the choice of suture anchor material can significantly impact the surgical outcome. Surgeons in both settings must consider factors such as the patient’s age, activity level, and any underlying health conditions when selecting the appropriate suture anchor. For example, a younger, more active patient might benefit from the strength and durability of alloy anchors, while an older patient with a slower healing process might be better suited for bioceramic anchors that promote bone integration. Bioabsorbable anchors might be chosen for patients who are concerned about the long-term presence of foreign materials in their body. The integration of advanced technologies, such as arthroscopic techniques and imaging guidance, has also improved the precision and effectiveness of rotator cuff repair surgeries in both hospitals and clinics. Arthroscopic surgery, which involves the use of a small camera and specialized instruments inserted through tiny incisions, allows for a less invasive approach to rotator cuff repair. This technique can reduce recovery times, minimize scarring, and lower the risk of complications compared to traditional open surgery. Both hospitals and clinics have increasingly adopted arthroscopic techniques, making rotator cuff repair surgeries more accessible and effective for a broader range of patients. Overall, the Global Rotator Cuff Repair Suture Anchor Market plays a crucial role in enabling successful surgical outcomes in both hospital and clinic settings. The choice of surgical setting often depends on the patient’s specific needs, the complexity of the surgery, and the availability of specialized care. Both hospitals and clinics continue to advance their capabilities in rotator cuff repair, driven by ongoing innovations in suture anchor materials and surgical techniques.

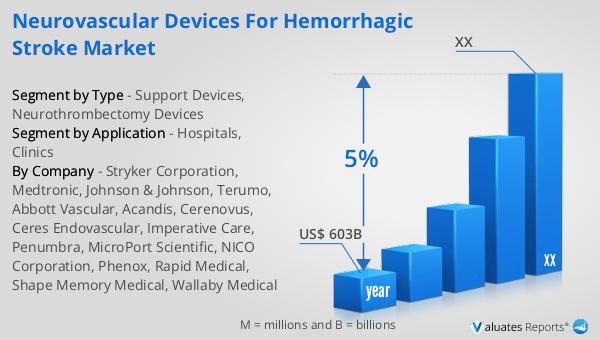

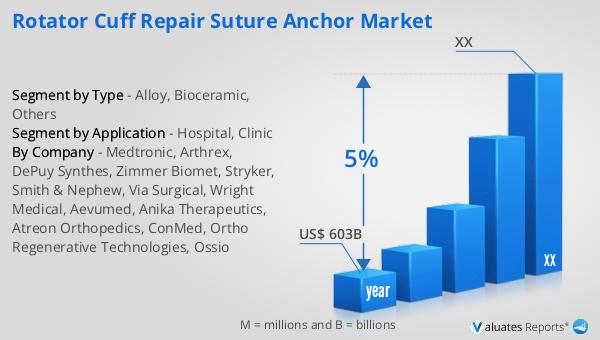

Global Rotator Cuff Repair Suture Anchor Market Outlook:

According to our research, the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This substantial market size reflects the increasing demand for advanced medical technologies and devices across various healthcare sectors. The steady growth rate indicates a robust and expanding market, driven by factors such as technological advancements, an aging population, and the rising prevalence of chronic diseases. The medical device industry encompasses a wide range of products, including diagnostic equipment, surgical instruments, and therapeutic devices, all of which contribute to improving patient outcomes and enhancing the quality of healthcare services. As the market continues to grow, it presents significant opportunities for innovation and investment, making it a dynamic and vital component of the global healthcare landscape.

| Report Metric | Details |

| Report Name | Rotator Cuff Repair Suture Anchor Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Medtronic, Arthrex, DePuy Synthes, Zimmer Biomet, Stryker, Smith & Nephew, Via Surgical, Wright Medical, Aevumed, Anika Therapeutics, Atreon Orthopedics, ConMed, Ortho Regenerative Technologies, Ossio |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |