What is Surfacing Machine- Global Market?

Surfacing machines are essential tools in various industries, designed to create smooth and even surfaces on different materials. These machines are integral to the manufacturing process, ensuring that products meet precise specifications and quality standards. The global market for surfacing machines is vast, encompassing a wide range of equipment used in industries such as automotive, aerospace, and construction. These machines are used to refine surfaces by removing excess material, creating a uniform finish that is crucial for both aesthetic and functional purposes. The demand for surfacing machines is driven by the need for high-quality finishes in manufacturing processes, which in turn enhances the durability and performance of the final products. As industries continue to evolve and demand more precise and efficient manufacturing techniques, the role of surfacing machines becomes increasingly important. The global market for these machines is expected to grow as technological advancements lead to more sophisticated and efficient models, catering to the diverse needs of various sectors.

Milling Machine, Grinding Machine in the Surfacing Machine- Global Market:

Milling machines and grinding machines are two primary types of surfacing machines that play a crucial role in the global market. Milling machines are used to remove material from a workpiece by feeding it against a rotating cutter. This process is essential in shaping and finishing products with precision, making milling machines indispensable in industries such as automotive and aerospace. These machines come in various types, including vertical and horizontal milling machines, each designed for specific applications. Vertical milling machines are often used for precision work, while horizontal machines are better suited for heavy-duty tasks. On the other hand, grinding machines are used to achieve a high-quality finish on a workpiece by using an abrasive wheel. These machines are essential for achieving the smooth surfaces required in many manufacturing processes. Grinding machines are used in a variety of applications, from sharpening tools to finishing surfaces on metal parts. The global market for these machines is driven by the need for high-quality finishes and the demand for precision in manufacturing processes. As industries continue to evolve, the demand for advanced milling and grinding machines is expected to grow, leading to innovations in machine design and functionality. The integration of advanced technologies such as computer numerical control (CNC) has further enhanced the capabilities of these machines, allowing for greater precision and efficiency. CNC milling and grinding machines are now widely used in industries that require high levels of accuracy and repeatability. These machines are capable of producing complex shapes and surfaces with minimal human intervention, making them ideal for mass production. The global market for milling and grinding machines is also influenced by the increasing demand for automation in manufacturing processes. Automated machines reduce the need for manual labor, increase production efficiency, and improve product quality. As a result, manufacturers are investing in advanced milling and grinding machines to stay competitive in the global market. The demand for these machines is also driven by the need for sustainable manufacturing practices. Milling and grinding machines that are energy-efficient and produce minimal waste are becoming increasingly popular as industries strive to reduce their environmental impact. The global market for these machines is expected to continue growing as manufacturers seek to improve their production processes and meet the demands of an ever-changing market.

Machinery Manufacturing, Automobile, Aerospace & Defense, Other in the Surfacing Machine- Global Market:

Surfacing machines are used in a variety of industries, each with its unique requirements and challenges. In the machinery manufacturing sector, surfacing machines are essential for producing high-quality components that meet precise specifications. These machines are used to create smooth and even surfaces on metal parts, ensuring that they fit together perfectly and function as intended. The demand for surfacing machines in this sector is driven by the need for precision and efficiency in manufacturing processes. In the automotive industry, surfacing machines are used to produce components such as engine parts, transmission systems, and body panels. These machines are essential for achieving the high-quality finishes required in the automotive industry, where even the smallest imperfections can affect the performance and safety of a vehicle. The demand for surfacing machines in this sector is driven by the need for high-quality finishes and the demand for precision in manufacturing processes. In the aerospace and defense industries, surfacing machines are used to produce components that meet strict quality and safety standards. These machines are essential for achieving the high-quality finishes required in these industries, where even the smallest imperfections can have serious consequences. The demand for surfacing machines in this sector is driven by the need for precision and efficiency in manufacturing processes. In other industries, such as construction and electronics, surfacing machines are used to produce components that meet specific requirements. These machines are essential for achieving the high-quality finishes required in these industries, where even the smallest imperfections can affect the performance and safety of a product. The demand for surfacing machines in these sectors is driven by the need for precision and efficiency in manufacturing processes. As industries continue to evolve and demand more precise and efficient manufacturing techniques, the role of surfacing machines becomes increasingly important. The global market for these machines is expected to grow as technological advancements lead to more sophisticated and efficient models, catering to the diverse needs of various sectors.

Surfacing Machine- Global Market Outlook:

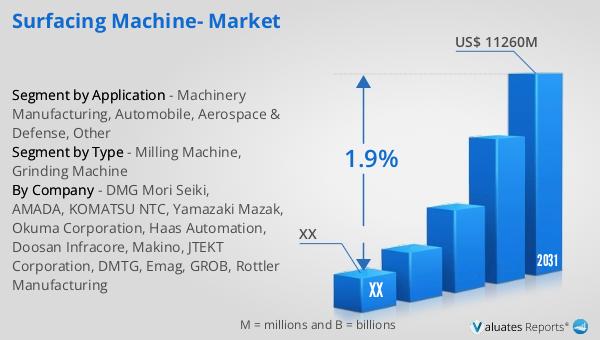

The global market for surfacing machines was valued at approximately $9,892 million in 2024, with projections indicating a growth to around $11,260 million by 2031. This growth represents a compound annual growth rate (CAGR) of 1.9% during the forecast period from 2025 to 2031. The market is characterized by a competitive landscape, with the top five players accounting for 25.55% of the global revenue share in 2019. This indicates a significant level of consolidation within the industry, where a few key players dominate the market. The growth in the surfacing machine market can be attributed to several factors, including the increasing demand for high-quality finishes in manufacturing processes and the need for precision and efficiency in various industries. As technological advancements continue to drive innovation in machine design and functionality, the market is expected to see further growth. The integration of advanced technologies such as computer numerical control (CNC) has enhanced the capabilities of surfacing machines, allowing for greater precision and efficiency. This has led to increased demand for these machines in industries that require high levels of accuracy and repeatability. Additionally, the growing trend towards automation in manufacturing processes is expected to drive further growth in the surfacing machine market. Automated machines reduce the need for manual labor, increase production efficiency, and improve product quality, making them an attractive investment for manufacturers. As a result, the global market for surfacing machines is expected to continue growing as manufacturers seek to improve their production processes and meet the demands of an ever-changing market.

| Report Metric | Details |

| Report Name | Surfacing Machine- Market |

| Forecasted market size in 2031 | US$ 11260 million |

| CAGR | 1.9% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | DMG Mori Seiki, AMADA, KOMATSU NTC, Yamazaki Mazak, Okuma Corporation, Haas Automation, Doosan Infracore, Makino, JTEKT Corporation, DMTG, Emag, GROB, Rottler Manufacturing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |