What is Global Synthetic Zeolite Y Adsorbent Market?

The Global Synthetic Zeolite Y Adsorbent Market is a specialized segment within the broader chemical industry, focusing on the production and application of synthetic zeolite Y adsorbents. These materials are crystalline aluminosilicates with a highly porous structure, making them excellent for adsorption processes. Synthetic zeolite Y is particularly valued for its uniform pore size and high thermal stability, which make it suitable for various industrial applications. The market for these adsorbents is driven by their use in sectors such as petrochemicals, water treatment, and environmental management. As industries continue to seek efficient and sustainable solutions for separation and purification processes, the demand for synthetic zeolite Y adsorbents is expected to grow. This market is characterized by ongoing research and development efforts aimed at enhancing the performance and cost-effectiveness of these materials. Additionally, the global push towards environmental sustainability is likely to further boost the adoption of synthetic zeolite Y adsorbents, as they offer a more environmentally friendly alternative to traditional adsorbents. Overall, the Global Synthetic Zeolite Y Adsorbent Market is poised for steady growth, driven by technological advancements and increasing industrial applications.

Hydrothermal Synthesis, Ion Exchange Method, Steam-assisted Crystallization in the Global Synthetic Zeolite Y Adsorbent Market:

Hydrothermal synthesis, ion exchange method, and steam-assisted crystallization are three key processes used in the production of synthetic zeolite Y adsorbents, each contributing to the material's unique properties and applications. Hydrothermal synthesis is a widely used method that involves crystallizing zeolites from a gel-like mixture of silica, alumina, and an alkaline solution under high temperature and pressure conditions. This process allows for the precise control of the zeolite's crystal structure and pore size, which are critical for its adsorption capabilities. The hydrothermal method is favored for its ability to produce high-purity zeolites with uniform properties, making it ideal for applications requiring consistent performance. The ion exchange method, on the other hand, involves replacing the cations in the zeolite's framework with other cations, such as sodium or calcium, to modify its adsorption characteristics. This process is particularly useful for tailoring the zeolite's selectivity and capacity for specific applications, such as gas separation or water purification. Ion exchange is a versatile technique that allows for the customization of zeolite properties to meet the specific needs of different industries. Steam-assisted crystallization is a relatively newer method that enhances the crystallization process by introducing steam into the reaction environment. This technique accelerates the formation of zeolite crystals and can improve the material's thermal stability and mechanical strength. Steam-assisted crystallization is gaining attention for its potential to reduce production costs and energy consumption, making it an attractive option for large-scale manufacturing of synthetic zeolite Y adsorbents. Each of these methods plays a crucial role in the development of zeolite Y adsorbents, offering distinct advantages and challenges. The choice of synthesis method depends on various factors, including the desired properties of the final product, production scale, and cost considerations. As the demand for high-performance adsorbents continues to rise, ongoing research and innovation in these synthesis techniques are essential to meet the evolving needs of the market. By optimizing these processes, manufacturers can enhance the efficiency and sustainability of zeolite production, ultimately contributing to the growth and competitiveness of the Global Synthetic Zeolite Y Adsorbent Market.

Water Treatment, Nuclear Waste Treatment, Gas Separation and Purification, VOC Treatment, Other in the Global Synthetic Zeolite Y Adsorbent Market:

The Global Synthetic Zeolite Y Adsorbent Market finds extensive usage across various sectors, including water treatment, nuclear waste treatment, gas separation and purification, volatile organic compound (VOC) treatment, and other industrial applications. In water treatment, synthetic zeolite Y adsorbents are employed to remove impurities and contaminants, such as heavy metals and organic compounds, from water sources. Their high ion-exchange capacity and selectivity make them effective in purifying drinking water and treating wastewater. The use of zeolite Y in water treatment not only improves water quality but also contributes to environmental sustainability by reducing the need for chemical additives. In the field of nuclear waste treatment, synthetic zeolite Y adsorbents play a critical role in immobilizing radioactive isotopes and preventing their release into the environment. Their ability to selectively adsorb specific ions makes them suitable for capturing and containing hazardous materials, thereby enhancing the safety and efficiency of nuclear waste management processes. Gas separation and purification is another significant application area for synthetic zeolite Y adsorbents. Their uniform pore size and high surface area enable the selective adsorption of gases, such as carbon dioxide, nitrogen, and hydrogen, from gas mixtures. This property is particularly valuable in industries such as petrochemicals and natural gas processing, where the separation and purification of gases are essential for product quality and process efficiency. In VOC treatment, synthetic zeolite Y adsorbents are used to capture and remove volatile organic compounds from industrial emissions and indoor air. Their high adsorption capacity and thermal stability make them effective in reducing air pollution and improving air quality. Additionally, synthetic zeolite Y adsorbents are utilized in various other applications, including catalysis, odor control, and moisture removal. Their versatility and effectiveness in diverse applications underscore the importance of synthetic zeolite Y adsorbents in addressing environmental and industrial challenges. As industries continue to prioritize sustainability and efficiency, the demand for synthetic zeolite Y adsorbents is expected to grow, driving further innovation and development in this market.

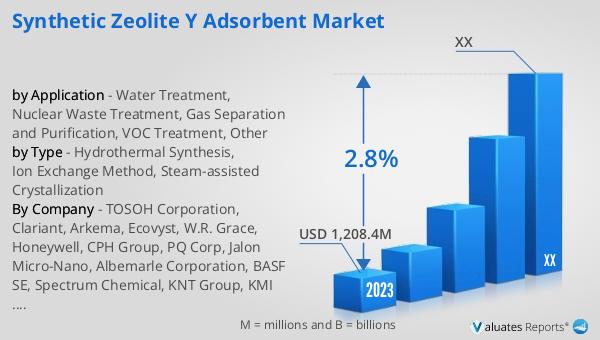

Global Synthetic Zeolite Y Adsorbent Market Outlook:

Between 2019 and 2023, the global market for synthetic Y-zeolite adsorbents experienced a compound annual growth rate (CAGR) of 2.8%. By 2023, the market had reached a valuation of USD 1208.4 million. Looking ahead, the market is anticipated to expand by more than 1.5 times by 2034. This growth trajectory is expected to be accompanied by a CAGR of 1.4%, which, while slightly lower than the historical CAGR, still indicates a steady upward trend. The market's expansion is driven by the increasing demand for efficient and sustainable adsorption solutions across various industries. As environmental regulations become more stringent and industries seek to optimize their processes, the adoption of synthetic Y-zeolite adsorbents is likely to rise. This growth is further supported by ongoing advancements in synthesis techniques and the development of new applications for these materials. Despite the challenges posed by economic fluctuations and competitive pressures, the Global Synthetic Zeolite Y Adsorbent Market is poised for continued growth, driven by its critical role in addressing environmental and industrial needs. As the market evolves, stakeholders are expected to focus on innovation and collaboration to capitalize on emerging opportunities and maintain a competitive edge.

| Report Metric | Details |

| Report Name | Synthetic Zeolite Y Adsorbent Market |

| Accounted market size in 2023 | USD 1,208.4 million |

| CAGR | 2.8% |

| Base Year | 2023 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | TOSOH Corporation, Clariant, Arkema, Ecovyst, W.R. Grace, Honeywell, CPH Group, PQ Corp, Jalon Micro-Nano, Albemarle Corporation, BASF SE, Spectrum Chemical, KNT Group, KMI Zeolite, Silkem |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |