What is Global Direct Roving for Thermoplastics Market?

The Global Direct Roving for Thermoplastics Market is a specialized segment within the broader composite materials industry, focusing on the production and application of direct roving, a type of glass fiber reinforcement used in thermoplastic composites. These composites are known for their lightweight, high strength, and durability, making them ideal for various industrial applications. Direct roving involves continuous strands of glass fibers that are bundled together without twisting, providing superior mechanical properties and ease of processing. The market for these materials is driven by the increasing demand for lightweight and high-performance materials in industries such as automotive, construction, and electronics. As manufacturers seek to improve fuel efficiency and reduce emissions, the use of thermoplastic composites is becoming more prevalent. Additionally, the recyclability of thermoplastics aligns with the growing emphasis on sustainability and environmental responsibility. The market is characterized by technological advancements, with companies investing in research and development to enhance the performance and cost-effectiveness of these materials. As a result, the Global Direct Roving for Thermoplastics Market is poised for growth, supported by the expanding applications and the need for innovative material solutions.

LFT Process, GMT Process, Others in the Global Direct Roving for Thermoplastics Market:

The LFT (Long Fiber Thermoplastics) process is a significant method within the Global Direct Roving for Thermoplastics Market, known for producing materials with enhanced mechanical properties. In this process, long fibers are incorporated into a thermoplastic matrix, resulting in composites that offer superior strength and impact resistance compared to short fiber alternatives. The LFT process typically involves the impregnation of continuous glass fibers with a thermoplastic resin, followed by the cutting of these impregnated fibers into pellets. These pellets are then molded into desired shapes using techniques such as injection molding or compression molding. The resulting composites are highly sought after in industries that require materials with high strength-to-weight ratios, such as automotive and aerospace. The GMT (Glass Mat Thermoplastics) process, on the other hand, involves the use of glass fiber mats that are impregnated with thermoplastic resins. This process is known for producing composites with excellent surface finish and dimensional stability. GMT composites are often used in applications where aesthetics and precision are critical, such as in the production of automotive interior components. The GMT process involves the layering of glass mats and thermoplastic films, followed by heating and compression to form the final composite. This method allows for the production of large and complex parts with consistent quality. Other processes within the Global Direct Roving for Thermoplastics Market include pultrusion and filament winding, which are used to produce continuous profiles and cylindrical structures, respectively. Pultrusion involves pulling continuous strands of glass fibers through a resin bath and then through a heated die to form profiles with constant cross-sections. This process is ideal for producing structural components such as beams and rods. Filament winding, on the other hand, involves winding continuous fibers around a rotating mandrel, creating hollow structures with high strength and stiffness. This process is commonly used in the production of pressure vessels and pipes. Each of these processes offers unique advantages and is selected based on the specific requirements of the application. The choice of process depends on factors such as the desired mechanical properties, the complexity of the part, and the production volume. As the demand for lightweight and high-performance materials continues to grow, these processes play a crucial role in the development of innovative solutions within the Global Direct Roving for Thermoplastics Market.

Automotive, Construction, Electrical and Electronics, Others in the Global Direct Roving for Thermoplastics Market:

The Global Direct Roving for Thermoplastics Market finds extensive usage across various industries, with the automotive sector being one of the primary beneficiaries. In the automotive industry, the demand for lightweight materials is driven by the need to improve fuel efficiency and reduce emissions. Direct roving for thermoplastics offers an ideal solution, providing high strength-to-weight ratios that contribute to the overall reduction in vehicle weight. These materials are used in the production of various automotive components, including bumpers, dashboards, and structural parts. The recyclability of thermoplastics also aligns with the automotive industry's focus on sustainability and environmental responsibility. In the construction industry, direct roving for thermoplastics is used to produce materials that offer durability, corrosion resistance, and ease of installation. These properties make them suitable for applications such as roofing, cladding, and insulation. The use of thermoplastic composites in construction also contributes to energy efficiency, as they provide excellent thermal insulation properties. In the electrical and electronics industry, direct roving for thermoplastics is used to produce components that require high dielectric strength and thermal stability. These materials are used in the production of circuit boards, connectors, and enclosures, where they provide excellent electrical insulation and resistance to heat and chemicals. The versatility of thermoplastic composites allows for their use in a wide range of electronic applications, from consumer electronics to industrial equipment. Other industries that benefit from the Global Direct Roving for Thermoplastics Market include the aerospace, marine, and sports equipment sectors. In aerospace, the demand for lightweight and high-performance materials is critical for improving fuel efficiency and reducing emissions. Thermoplastic composites offer an ideal solution, providing the necessary strength and durability for aerospace applications. In the marine industry, these materials are used to produce components that require resistance to water and corrosion, such as boat hulls and decks. The sports equipment industry also benefits from the use of thermoplastic composites, as they provide the necessary strength and flexibility for products such as bicycles, tennis rackets, and skis. Overall, the Global Direct Roving for Thermoplastics Market plays a crucial role in providing innovative material solutions across a wide range of industries, contributing to improved performance, sustainability, and efficiency.

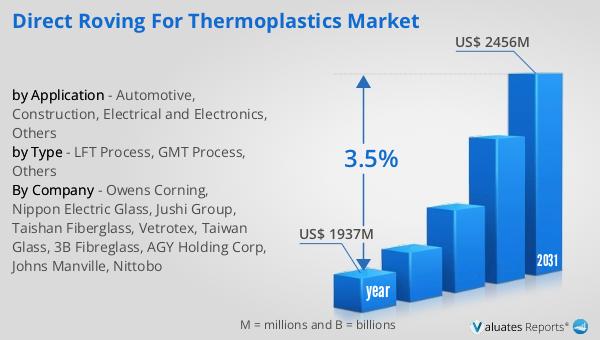

Global Direct Roving for Thermoplastics Market Outlook:

The worldwide market for Direct Roving for Thermoplastics was estimated to be worth $1,937 million in 2024. It is anticipated to expand to a revised valuation of $2,456 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.5% over the forecast period. This growth trajectory underscores the increasing demand for high-performance materials across various industries. The market's expansion is driven by the need for lightweight and durable materials that can enhance product performance while also contributing to sustainability goals. As industries such as automotive, construction, and electronics continue to evolve, the demand for innovative material solutions is expected to rise. The recyclability of thermoplastics further supports this growth, as it aligns with the global emphasis on environmental responsibility and resource efficiency. Companies operating in this market are investing in research and development to enhance the performance and cost-effectiveness of direct roving for thermoplastics, ensuring they meet the evolving needs of their customers. The market's growth is also supported by technological advancements that enable the production of high-quality composites with improved mechanical properties. As a result, the Global Direct Roving for Thermoplastics Market is poised for continued growth, driven by the expanding applications and the need for innovative material solutions.

| Report Metric | Details |

| Report Name | Direct Roving for Thermoplastics Market |

| Accounted market size in year | US$ 1937 million |

| Forecasted market size in 2031 | US$ 2456 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Owens Corning, Nippon Electric Glass, Jushi Group, Taishan Fiberglass, Vetrotex, Taiwan Glass, 3B Fibreglass, AGY Holding Corp, Johns Manville, Nittobo |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |