What is Global Spring Loaded Pressure Vacuum Relief Valve Market?

The Global Spring Loaded Pressure Vacuum Relief Valve Market is a specialized segment within the broader industrial valve industry. These valves are crucial components used to maintain safety and operational efficiency in various industrial applications. They are designed to protect tanks and processing systems from excessive pressure or vacuum conditions, which can lead to equipment failure or hazardous situations. The valves operate by opening at a predetermined pressure or vacuum level, allowing excess pressure to escape or air to enter, thus stabilizing the system. This market is driven by the increasing demand for safety and efficiency in industries such as petrochemicals, pharmaceuticals, and food and beverages. The growth of these industries, coupled with stringent safety regulations, has led to a steady demand for these valves. Additionally, technological advancements have resulted in more efficient and reliable valve designs, further boosting their adoption. The market is characterized by a mix of established players and new entrants, each striving to offer innovative solutions to meet the evolving needs of their customers. Overall, the Global Spring Loaded Pressure Vacuum Relief Valve Market plays a vital role in ensuring the safe and efficient operation of industrial processes worldwide.

in the Global Spring Loaded Pressure Vacuum Relief Valve Market:

The Global Spring Loaded Pressure Vacuum Relief Valve Market offers a variety of valve types to cater to the diverse needs of its customers. These valves are primarily categorized based on their design, material, and application. One of the most common types is the conventional spring-loaded valve, which uses a spring mechanism to control the opening and closing of the valve. This type is widely used due to its simplicity and reliability. Another popular type is the pilot-operated valve, which uses a pilot valve to control the main valve. This design allows for more precise control and is often used in applications where accuracy is critical. In terms of materials, these valves are typically made from metals such as stainless steel, carbon steel, and aluminum, each offering different levels of durability and resistance to corrosion. Stainless steel valves are preferred in industries where hygiene and corrosion resistance are paramount, such as food and pharmaceuticals. Carbon steel valves, on the other hand, are favored in applications where high strength is required. Aluminum valves are lightweight and are used in applications where weight is a concern. Additionally, there are specialized valves designed for specific applications, such as cryogenic valves for low-temperature applications and high-pressure valves for demanding environments. Customers choose these valves based on factors such as the operating conditions, the nature of the fluid being handled, and the specific requirements of their application. For instance, in the petrochemical industry, valves must withstand harsh chemicals and high temperatures, while in the food industry, they must meet strict hygiene standards. The choice of valve type also depends on the desired level of automation, with some customers opting for manually operated valves and others for automated systems that can be integrated into a larger control system. Overall, the variety of valve types available in the Global Spring Loaded Pressure Vacuum Relief Valve Market ensures that customers can find a solution that meets their specific needs, whether they require a simple, cost-effective valve or a sophisticated, high-performance system.

Petrochemical Engineering, Pharmacy, Food & Beverage, Others in the Global Spring Loaded Pressure Vacuum Relief Valve Market:

The Global Spring Loaded Pressure Vacuum Relief Valve Market finds extensive usage across various industries, each with its unique requirements and challenges. In the petrochemical engineering sector, these valves are essential for maintaining safety and efficiency in the processing of chemicals and hydrocarbons. They help prevent overpressure and vacuum conditions in storage tanks and processing equipment, which can lead to catastrophic failures or environmental hazards. The harsh operating conditions in this industry, including high temperatures and corrosive substances, necessitate the use of robust and reliable valves. In the pharmaceutical industry, these valves play a critical role in ensuring the integrity of production processes. They help maintain the required pressure levels in reactors and storage vessels, preventing contamination and ensuring product quality. The stringent regulatory requirements in this industry demand the use of high-quality valves that meet specific hygiene and safety standards. In the food and beverage industry, spring-loaded pressure vacuum relief valves are used to protect storage tanks and processing equipment from pressure fluctuations. They help maintain the quality and safety of food products by preventing contamination and spoilage. The valves used in this industry must comply with strict hygiene standards and are often made from materials that are resistant to corrosion and easy to clean. Beyond these industries, these valves are also used in other sectors such as water treatment, power generation, and oil and gas. In each of these applications, the valves help ensure the safe and efficient operation of equipment by preventing pressure-related issues. The versatility and reliability of spring-loaded pressure vacuum relief valves make them an indispensable component in a wide range of industrial applications.

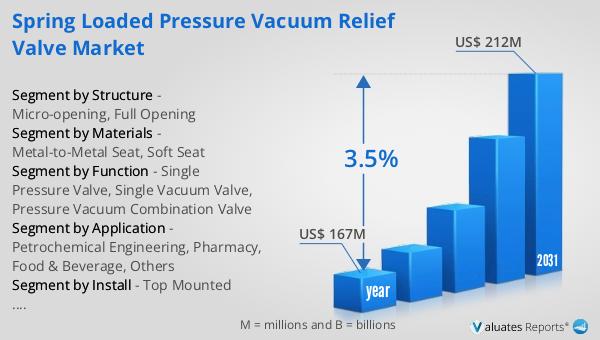

Global Spring Loaded Pressure Vacuum Relief Valve Market Outlook:

The global market for Spring Loaded Pressure Vacuum Relief Valves was valued at $167 million in 2024, with projections indicating it will grow to a revised size of $212 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.5% over the forecast period. This steady growth can be attributed to several factors, including the increasing demand for safety and efficiency in industrial processes. As industries continue to expand and evolve, the need for reliable and efficient pressure relief solutions becomes more critical. The market's growth is also driven by technological advancements that have led to the development of more efficient and reliable valve designs. These innovations have made it possible for industries to operate more safely and efficiently, further boosting the demand for these valves. Additionally, the growing emphasis on environmental safety and regulatory compliance has led to increased adoption of these valves across various industries. As companies strive to meet stringent safety and environmental standards, the demand for high-quality pressure relief solutions is expected to rise. Overall, the Global Spring Loaded Pressure Vacuum Relief Valve Market is poised for steady growth, driven by the increasing need for safety and efficiency in industrial processes.

| Report Metric | Details |

| Report Name | Spring Loaded Pressure Vacuum Relief Valve Market |

| Accounted market size in year | US$ 167 million |

| Forecasted market size in 2031 | US$ 212 million |

| CAGR | 3.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Function |

|

| Segment by Structure |

|

| Segment by Install |

|

| Segment by Materials |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Motherwell, Emerson, KITO Armaturen, PROTEGO, Äager, Groth Corporation, Farris Engineering, Finekay, OPW, Apollo |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |