What is Global Metal Powder Gas Atomization Equipment Market?

The Global Metal Powder Gas Atomization Equipment Market is a specialized segment within the broader industrial machinery sector, focusing on the production of metal powders through gas atomization processes. This market is crucial for industries that require high-quality metal powders, such as aerospace, automotive, and electronics, where precision and material properties are paramount. Gas atomization is a process where molten metal is dispersed into fine droplets using a high-pressure gas stream, resulting in spherical metal powders with uniform size and composition. These powders are essential for advanced manufacturing techniques like additive manufacturing, also known as 3D printing, and powder metallurgy. The market's growth is driven by the increasing demand for lightweight and high-strength materials, technological advancements in atomization equipment, and the expanding applications of metal powders in various industries. As industries continue to innovate and seek more efficient production methods, the demand for high-quality metal powders and the equipment used to produce them is expected to rise, making this market a vital component of modern manufacturing processes.

Vacuum Inert Gas Atomization Device, Electrode Induction Atomization Device, Others in the Global Metal Powder Gas Atomization Equipment Market:

The Global Metal Powder Gas Atomization Equipment Market encompasses various types of devices, each designed to cater to specific needs and applications. Among these, the Vacuum Inert Gas Atomization Device is a prominent type, known for its ability to produce high-purity metal powders. This device operates under a vacuum or inert gas atmosphere, which prevents oxidation and contamination of the metal powders during the atomization process. The result is a high-quality powder with excellent flowability and uniform particle size, making it ideal for applications in industries where material purity is critical, such as aerospace and medical implants. The Electrode Induction Atomization Device, on the other hand, utilizes an induction coil to melt the metal, which is then atomized using a gas stream. This method is particularly effective for producing powders from high-melting-point metals and alloys. The induction heating allows for precise control over the melting process, ensuring consistent quality and properties of the resulting powders. This device is often used in the production of specialized alloys and materials for high-performance applications. Other types of equipment in this market include centrifugal atomization devices and ultrasonic atomization devices. Centrifugal atomization involves spinning the molten metal at high speeds to create fine droplets, which solidify into powders. This method is suitable for producing large quantities of powder with a relatively simple setup. Ultrasonic atomization, meanwhile, uses high-frequency sound waves to break up the molten metal into fine droplets. This technique is particularly useful for producing ultra-fine powders with narrow particle size distributions, which are essential for certain advanced manufacturing processes. Each of these devices plays a crucial role in the Global Metal Powder Gas Atomization Equipment Market, catering to the diverse needs of industries that rely on high-quality metal powders for their products and processes. As technology continues to advance, these devices are expected to become more efficient and capable, further driving the growth of this market.

Metal Powder Manufacturer, Universities and Research Institutes in the Global Metal Powder Gas Atomization Equipment Market:

The usage of Global Metal Powder Gas Atomization Equipment Market is extensive and varied, particularly in areas such as Metal Powder Manufacturers, Universities, and Research Institutes. Metal Powder Manufacturers are perhaps the most direct users of gas atomization equipment. These manufacturers rely on the precision and efficiency of gas atomization processes to produce high-quality metal powders that meet the stringent requirements of their clients. The ability to produce powders with specific particle sizes, shapes, and material properties is crucial for manufacturers looking to supply industries such as aerospace, automotive, and electronics. The equipment allows them to produce powders that are not only high in quality but also consistent in their properties, which is essential for maintaining the integrity and performance of the final products. Universities and Research Institutes, on the other hand, utilize gas atomization equipment for a different purpose. In these settings, the equipment is often used for research and development activities, exploring new materials and processes that could lead to breakthroughs in various fields. Researchers use gas atomization to produce experimental metal powders that can be tested and analyzed for their properties and potential applications. This research is vital for advancing our understanding of materials science and for developing new technologies that can benefit a wide range of industries. The ability to produce small batches of custom metal powders allows researchers to experiment with different compositions and processing conditions, leading to innovations that can eventually be scaled up for commercial production. In both cases, the Global Metal Powder Gas Atomization Equipment Market plays a crucial role in enabling the production and development of high-quality metal powders. Whether it's for large-scale manufacturing or cutting-edge research, the equipment provides the tools needed to produce powders that meet the specific needs of each application. As industries continue to evolve and demand more advanced materials, the importance of gas atomization equipment in these areas is only expected to grow.

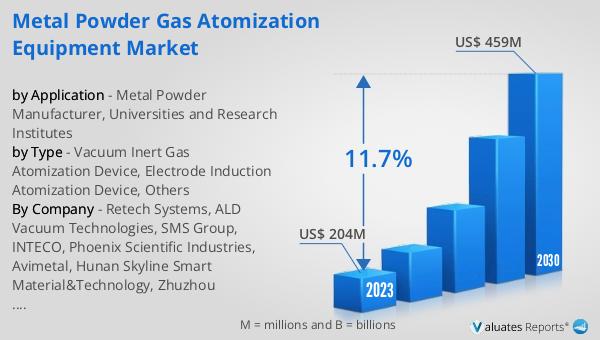

Global Metal Powder Gas Atomization Equipment Market Outlook:

The outlook for the Global Metal Powder Gas Atomization Equipment Market indicates a significant growth trajectory, with the market expected to expand from $236 million in 2024 to $507 million by 2031. This growth, at a compound annual growth rate (CAGR) of 11.7% from 2025 to 2031, is driven by the increasing demand for high-quality metal powders across various industries. Critical product segments and diverse end-use applications are key factors contributing to this growth, as industries such as aerospace, automotive, and electronics continue to seek advanced materials for their products. However, the market is not without its challenges. Evolving U.S. tariff policies introduce a level of trade-cost volatility and supply-chain uncertainty that could impact the market's growth. These policies can affect the cost of raw materials and the overall production costs for manufacturers, potentially leading to fluctuations in pricing and availability of metal powders. Despite these challenges, the market's growth prospects remain strong, driven by technological advancements in atomization equipment and the expanding applications of metal powders in various industries. As manufacturers and researchers continue to innovate and explore new possibilities, the demand for high-quality metal powders and the equipment used to produce them is expected to rise, making this market a vital component of modern manufacturing processes.

| Report Metric | Details |

| Report Name | Metal Powder Gas Atomization Equipment Market |

| Accounted market size in 2024 | US$ 236 million |

| Forecasted market size in 2031 | US$ 507 million |

| CAGR | 11.7% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Retech Systems, ALD Vacuum Technologies, SMS Group, INTECO, Phoenix Scientific Industries, Avimetal, Hunan Skyline Smart Material&Technology, Zhuzhou ShuangLing Technology, Italimpianti, Zhuzhou Hanhe Industrial Equipment, Topcast, Consarc, Arcast |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |