What is Global Inspection Rewinder for Flexible Packaging Market?

The Global Inspection Rewinder for Flexible Packaging Market is a specialized segment within the broader packaging industry that focuses on the quality control and finishing processes of flexible packaging materials. These materials include films, foils, and laminates used in various industries such as food and beverage, pharmaceuticals, and consumer goods. Inspection rewinders are machines designed to inspect, rewind, and sometimes slit these materials to ensure they meet quality standards before they are shipped to customers or used in production. The market for these machines is driven by the increasing demand for high-quality packaging solutions that can preserve product integrity and extend shelf life. As consumer preferences shift towards more sustainable and efficient packaging options, the need for advanced inspection and rewinding technologies has grown. This market is characterized by technological advancements, such as the integration of automated inspection systems and real-time data analytics, which enhance the accuracy and efficiency of the inspection process. Companies operating in this market are continually innovating to offer solutions that can handle a wide range of materials and packaging formats, catering to the diverse needs of manufacturers and packagers worldwide.

One Side Inspection Rewinder, Both sides Inspection Rewinder in the Global Inspection Rewinder for Flexible Packaging Market:

In the realm of the Global Inspection Rewinder for Flexible Packaging Market, two primary types of machines are prevalent: One Side Inspection Rewinders and Both Sides Inspection Rewinders. One Side Inspection Rewinders are designed to inspect and rewind flexible packaging materials from one side. These machines are typically used when the primary concern is the quality of the printed or coated surface of the material. They are equipped with advanced sensors and cameras that can detect defects such as misprints, scratches, or coating inconsistencies. The rewinding process ensures that the material is neatly wound and ready for further processing or shipment. These machines are often favored for their simplicity and cost-effectiveness, especially in applications where the reverse side of the material does not require inspection. On the other hand, Both Sides Inspection Rewinders offer a more comprehensive solution by inspecting both sides of the flexible packaging material. This is particularly important in applications where both the printed and unprinted sides of the material need to meet stringent quality standards. These machines are equipped with dual inspection systems that can simultaneously monitor both surfaces for defects. This dual inspection capability is crucial in industries such as pharmaceuticals and food packaging, where even minor defects can compromise product safety and quality. Both Sides Inspection Rewinders are generally more complex and expensive than their one-sided counterparts, but they offer a higher level of assurance in terms of quality control. The choice between these two types of machines often depends on the specific requirements of the packaging application, including the type of material being processed, the desired level of inspection, and budget constraints. As the demand for high-quality flexible packaging continues to grow, manufacturers are increasingly investing in both types of inspection rewinders to ensure their products meet the highest standards of quality and safety.

Printed Film, Label, Composite Film, Others in the Global Inspection Rewinder for Flexible Packaging Market:

The Global Inspection Rewinder for Flexible Packaging Market finds its application across various areas, including Printed Film, Label, Composite Film, and others. In the realm of Printed Film, inspection rewinders play a crucial role in ensuring that the printed graphics and text on packaging materials are free from defects. These machines can detect issues such as color variations, misalignments, and print defects, which are critical in maintaining brand integrity and consumer trust. For labels, inspection rewinders are essential in verifying the accuracy and quality of printed information, such as barcodes, product details, and branding elements. Any errors in label printing can lead to significant issues in product identification and traceability, making inspection rewinders an indispensable tool in the label production process. In the case of Composite Films, which are often used in high-barrier packaging applications, inspection rewinders help ensure that the layers of materials are correctly laminated and free from defects that could compromise the barrier properties. These films are used in packaging sensitive products such as pharmaceuticals and perishable foods, where maintaining product integrity is paramount. Other applications of inspection rewinders include the inspection of specialty films and foils used in various industrial and consumer applications. These machines help manufacturers maintain high-quality standards, reduce waste, and improve operational efficiency by identifying and correcting defects early in the production process. As the demand for flexible packaging continues to rise, the role of inspection rewinders in ensuring quality and compliance with industry standards becomes increasingly important.

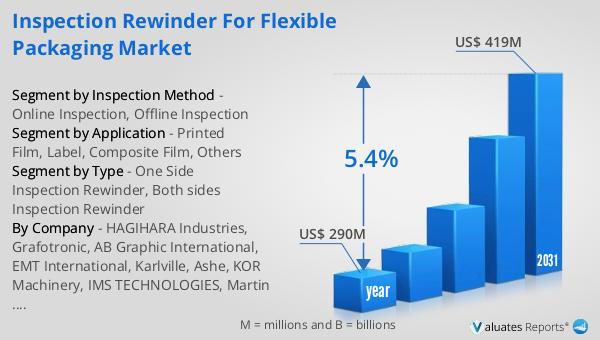

Global Inspection Rewinder for Flexible Packaging Market Outlook:

The global market for Inspection Rewinder for Flexible Packaging was valued at approximately $290 million in 2024. This market is anticipated to grow significantly, reaching an estimated size of $419 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.4% over the forecast period. The increasing demand for flexible packaging solutions across various industries, including food and beverage, pharmaceuticals, and consumer goods, is a key driver of this market expansion. As manufacturers strive to meet the evolving needs of consumers and regulatory requirements, the adoption of advanced inspection and rewinding technologies is expected to rise. These technologies not only enhance the quality and safety of packaging materials but also improve operational efficiency and reduce waste. The market's growth is further supported by technological advancements, such as the integration of automated inspection systems and real-time data analytics, which offer enhanced accuracy and efficiency in the inspection process. As a result, companies operating in this market are investing in research and development to offer innovative solutions that cater to the diverse needs of manufacturers and packagers worldwide. This positive market outlook underscores the importance of inspection rewinders in ensuring the quality and integrity of flexible packaging materials.

| Report Metric | Details |

| Report Name | Inspection Rewinder for Flexible Packaging Market |

| Accounted market size in year | US$ 290 million |

| Forecasted market size in 2031 | US$ 419 million |

| CAGR | 5.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Inspection Method |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | HAGIHARA Industries, Grafotronic, AB Graphic International, EMT International, Karlville, Ashe, KOR Machinery, IMS TECHNOLOGIES, Martin Automatic, Mark Andy, Beijing LUSTER LightTech Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |