What is Global Food Thermoforming Stretch Film Packaging Machine Market?

The Global Food Thermoforming Stretch Film Packaging Machine Market is a specialized segment within the packaging machinery industry, focusing on machines that utilize thermoforming technology to create stretch film packaging for food products. These machines are designed to heat a plastic film until it becomes pliable, then stretch and mold it over a product or a mold to create a secure and protective packaging. This type of packaging is particularly valued for its ability to extend the shelf life of food products by providing a tight seal that protects against contaminants and preserves freshness. The market for these machines is driven by the increasing demand for efficient and cost-effective packaging solutions in the food industry, as well as the growing emphasis on reducing food waste. As consumers continue to seek convenience and quality in their food purchases, the demand for advanced packaging technologies like thermoforming stretch film machines is expected to rise. These machines are used across various food sectors, including delicatessen, frozen meat, aquatic products, fruits, and vegetables, highlighting their versatility and importance in modern food packaging. The market is characterized by technological advancements, with manufacturers focusing on improving machine efficiency, speed, and sustainability to meet the evolving needs of the food industry.

Fully Automatic, Semi-automatic in the Global Food Thermoforming Stretch Film Packaging Machine Market:

In the Global Food Thermoforming Stretch Film Packaging Machine Market, machines are categorized based on their level of automation, primarily into fully automatic and semi-automatic machines. Fully automatic machines are designed to operate with minimal human intervention, offering high efficiency and speed in packaging processes. These machines are equipped with advanced sensors and control systems that allow them to perform complex packaging tasks with precision and consistency. They are ideal for large-scale food production facilities where high throughput and consistent quality are critical. Fully automatic machines can handle a wide range of packaging sizes and shapes, making them versatile for different food products. On the other hand, semi-automatic machines require some level of human involvement in the packaging process. While they offer less speed and efficiency compared to fully automatic machines, they provide greater flexibility and control over the packaging process. Semi-automatic machines are often preferred by small to medium-sized food producers who need to balance cost with operational efficiency. These machines allow operators to manually adjust settings and intervene in the packaging process as needed, providing a level of customization that fully automatic machines may not offer. Both types of machines play a crucial role in the food packaging industry, catering to different needs and production scales. The choice between fully automatic and semi-automatic machines depends on various factors, including production volume, budget, and specific packaging requirements. As the food industry continues to evolve, manufacturers of thermoforming stretch film packaging machines are focusing on enhancing the capabilities of both fully automatic and semi-automatic machines. This includes integrating smart technologies, such as IoT and AI, to improve machine performance and enable predictive maintenance. Additionally, there is a growing emphasis on sustainability, with manufacturers exploring eco-friendly materials and energy-efficient designs to reduce the environmental impact of packaging processes. The development of hybrid machines that combine the benefits of both fully automatic and semi-automatic systems is also an emerging trend in the market. These machines offer the speed and efficiency of fully automatic systems while providing the flexibility and control of semi-automatic machines, making them an attractive option for food producers looking to optimize their packaging operations. Overall, the Global Food Thermoforming Stretch Film Packaging Machine Market is characterized by a diverse range of machines that cater to the varying needs of the food industry, with ongoing innovations aimed at improving efficiency, sustainability, and adaptability.

Delicatessen, Frozen Meat, Aquatic Products, Fruits and Vegetables, Others in the Global Food Thermoforming Stretch Film Packaging Machine Market:

The Global Food Thermoforming Stretch Film Packaging Machine Market finds extensive usage across various food sectors, including delicatessen, frozen meat, aquatic products, fruits, and vegetables. In the delicatessen sector, these machines are used to package a wide range of ready-to-eat products, such as sliced meats, cheeses, and salads. The thermoforming stretch film packaging provides a tight seal that helps maintain the freshness and quality of these products, extending their shelf life and reducing food waste. The ability to customize packaging sizes and shapes is particularly beneficial for delicatessen products, which often come in varying portions and configurations. In the frozen meat sector, thermoforming stretch film packaging machines are essential for preserving the quality and safety of meat products during storage and transportation. The packaging provides a barrier against moisture and contaminants, preventing freezer burn and ensuring that the meat retains its flavor and texture. The machines can handle different types of meat products, from whole cuts to ground meat, offering flexibility and efficiency in packaging operations. For aquatic products, such as fish and seafood, thermoforming stretch film packaging machines offer similar benefits. The packaging helps maintain the freshness and quality of these perishable products, protecting them from spoilage and contamination. The machines can accommodate various packaging formats, from vacuum-sealed packs to modified atmosphere packaging, depending on the specific requirements of the product. In the fruits and vegetables sector, thermoforming stretch film packaging machines are used to package fresh produce, providing a protective barrier that helps extend shelf life and reduce spoilage. The packaging can be customized to accommodate different types of produce, from whole fruits and vegetables to pre-cut and ready-to-eat options. The machines offer flexibility in packaging design, allowing producers to create visually appealing packages that enhance product presentation and appeal to consumers. Beyond these specific sectors, thermoforming stretch film packaging machines are also used in other areas of the food industry, such as bakery products, dairy, and snacks. The versatility and efficiency of these machines make them an essential tool for food producers looking to optimize their packaging operations and meet the demands of modern consumers. As the food industry continues to evolve, the usage of thermoforming stretch film packaging machines is expected to grow, driven by the increasing demand for convenient, high-quality, and sustainable packaging solutions.

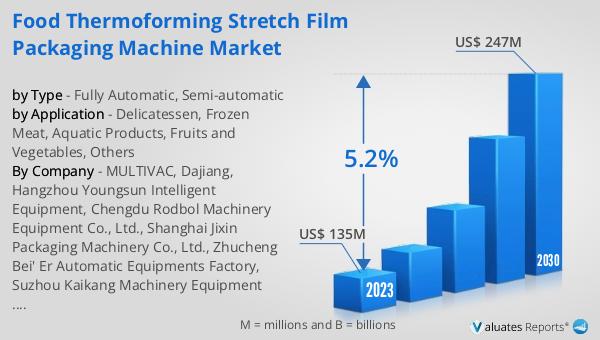

Global Food Thermoforming Stretch Film Packaging Machine Market Outlook:

The outlook for the Global Food Thermoforming Stretch Film Packaging Machine Market indicates a promising growth trajectory, with the market expected to expand from $182 million in 2024 to $258 million by 2031. This growth, at a compound annual growth rate (CAGR) of 5.2% from 2025 to 2031, is fueled by the increasing demand for efficient and versatile packaging solutions across various food sectors. The market's expansion is supported by critical product segments and diverse end-use applications, highlighting the importance of these machines in modern food packaging. However, the evolving U.S. tariff policies introduce an element of trade-cost volatility and supply-chain uncertainty, which could impact the market dynamics. These policies may lead to fluctuations in the cost of raw materials and components, affecting the pricing and availability of thermoforming stretch film packaging machines. Despite these challenges, the market is poised for growth as manufacturers continue to innovate and adapt to changing industry needs. The focus on sustainability and efficiency is driving the development of advanced machines that offer improved performance and reduced environmental impact. As the food industry continues to prioritize convenience, quality, and sustainability, the demand for thermoforming stretch film packaging machines is expected to rise, supporting the market's growth in the coming years.

| Report Metric | Details |

| Report Name | Food Thermoforming Stretch Film Packaging Machine Market |

| Accounted market size in 2024 | US$ 182 million |

| Forecasted market size in 2031 | US$ 258 million |

| CAGR | 5.2% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | MULTIVAC, Dajiang, Hangzhou Youngsun Intelligent Equipment, Chengdu Rodbol Machinery Equipment Co., Ltd., Shanghai Jixin Packaging Machinery Co., Ltd., Zhucheng Bei' Er Automatic Equipments Factory, Suzhou Kaikang Machinery Equipment Co.,Ltd., Jiyi Machinery, Ilpra, Brown Machine, Kangbeite Packaging, Wenzhou Chunlai, Nichrome |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |