What is Global Cast Polypropylene Films for Packaging Market?

The Global Cast Polypropylene (CPP) Films for Packaging Market is a dynamic and evolving sector within the packaging industry. CPP films are a type of plastic film made from polypropylene, a versatile polymer known for its excellent clarity, flexibility, and moisture resistance. These films are produced through a casting process, which involves melting the polypropylene and then cooling it on a chill roll to form a thin, uniform film. This process results in films that are highly transparent and have a smooth surface, making them ideal for packaging applications. The global market for CPP films is driven by their increasing use in various industries, including food, pharmaceuticals, and textiles, due to their cost-effectiveness and superior performance characteristics. As consumer demand for packaged goods continues to rise, the need for efficient and reliable packaging solutions like CPP films is expected to grow. Additionally, advancements in film technology and the development of new applications are further propelling the market forward. The market is characterized by a diverse range of products, including general films, metallized films, and retort films, each catering to specific packaging needs. With a strong presence in regions like Asia-Pacific, Europe, and North America, the CPP films market is poised for continued expansion as it adapts to changing consumer preferences and regulatory requirements.

General Film, Metalized Film, Retort Film, Others in the Global Cast Polypropylene Films for Packaging Market:

In the Global Cast Polypropylene Films for Packaging Market, several types of films cater to different packaging needs, each offering unique properties and benefits. General CPP films are the most widely used type, known for their excellent clarity, flexibility, and moisture resistance. These films are ideal for packaging applications that require a clear view of the product, such as food packaging, where visibility is crucial for consumer appeal. General CPP films are also used in applications where a high level of flexibility is needed, such as in the packaging of irregularly shaped items. Metallized CPP films, on the other hand, are coated with a thin layer of metal, usually aluminum, to enhance their barrier properties. This metallization process gives the films a shiny, reflective appearance and significantly improves their ability to block out light, oxygen, and moisture. As a result, metallized CPP films are commonly used in packaging applications that require extended shelf life and protection from external elements, such as snack foods, coffee, and other perishable goods. Retort CPP films are designed to withstand high-temperature processing, making them suitable for packaging products that undergo sterilization or pasteurization. These films are used in the packaging of ready-to-eat meals, soups, and sauces, where the packaging must endure the rigors of heat treatment without compromising the integrity of the seal or the quality of the product. Other types of CPP films include anti-fog films, which are treated to prevent condensation from forming on the inside of the packaging, ensuring clear visibility of the product. These films are particularly useful in the packaging of fresh produce and refrigerated items. Additionally, there are specialty CPP films designed for specific applications, such as high-barrier films for sensitive products and films with enhanced printability for branding and marketing purposes. Each type of CPP film is engineered to meet the specific requirements of its intended application, providing manufacturers and consumers with a wide range of options to choose from. The versatility and adaptability of CPP films make them a popular choice in the packaging industry, as they can be tailored to meet the diverse needs of different products and markets. As the demand for innovative and sustainable packaging solutions continues to grow, the development of new CPP film technologies and applications is expected to drive further growth in the market.

Food Packaging, Drug Packaging, Clothing Packaging, Others in the Global Cast Polypropylene Films for Packaging Market:

The usage of Global Cast Polypropylene Films for Packaging Market spans across various sectors, each benefiting from the unique properties of CPP films. In the food packaging industry, CPP films are highly valued for their clarity, flexibility, and moisture resistance. These films provide an excellent barrier against moisture and contaminants, ensuring the freshness and quality of food products. They are commonly used for packaging snacks, bakery items, fresh produce, and frozen foods, where visibility and protection are paramount. The ability of CPP films to be heat-sealed also makes them ideal for creating airtight packages that extend the shelf life of perishable goods. In the pharmaceutical sector, CPP films are used for drug packaging due to their excellent barrier properties and chemical resistance. These films protect medications from moisture, oxygen, and light, which can degrade the efficacy of the drugs. CPP films are used in blister packs, sachets, and strip packs, providing a reliable and cost-effective solution for pharmaceutical packaging. The clothing packaging industry also benefits from the use of CPP films, as they offer a clear and attractive presentation of garments while protecting them from dust, moisture, and handling damage. CPP films are used in the packaging of shirts, dresses, and other apparel items, where the clarity of the film enhances the visual appeal of the product. Additionally, CPP films are used in the packaging of textiles and home furnishings, providing a protective barrier that maintains the quality and appearance of the products. Beyond these specific applications, CPP films are used in a variety of other sectors, including electronics, automotive, and personal care products. Their versatility and adaptability make them suitable for a wide range of packaging needs, from protective wraps for electronic components to hygienic packaging for personal care items. The ability to customize CPP films with features such as anti-static properties, UV resistance, and enhanced printability further expands their usage across different industries. As consumer demand for sustainable and efficient packaging solutions continues to rise, the use of CPP films is expected to grow, driven by their ability to meet the diverse needs of various markets.

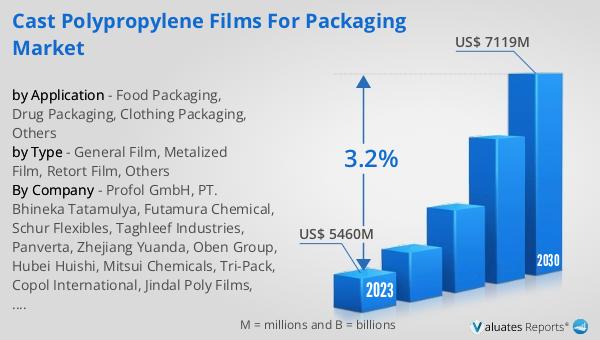

Global Cast Polypropylene Films for Packaging Market Outlook:

The outlook for the Global Cast Polypropylene Films for Packaging Market indicates a promising growth trajectory, with the market expected to expand from $5,890 million in 2024 to $7,325 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.2% from 2025 to 2031. This growth is driven by the critical product segments and diverse end-use applications that CPP films cater to. However, evolving U.S. tariff policies introduce trade-cost volatility and supply-chain uncertainty, which could impact market dynamics. The market is characterized by a competitive landscape, with the top five companies holding approximately 10% of the market share. Asia-Pacific emerges as the largest market, accounting for about 60% of the global share, followed by Europe and North America with shares of approximately 20% and 15%, respectively. Among the product segments, general CPP film stands out as the largest, with a share exceeding 45%. This dominance is attributed to the film's versatility and wide range of applications across various industries. As the market continues to evolve, manufacturers are focusing on innovation and sustainability to meet the changing demands of consumers and regulatory requirements. The development of new film technologies and the exploration of untapped markets are expected to further drive the growth of the CPP films market in the coming years.

| Report Metric | Details |

| Report Name | Cast Polypropylene Films for Packaging Market |

| Accounted market size in 2024 | US$ 5890 million |

| Forecasted market size in 2031 | US$ 7325 million |

| CAGR | 3.2% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Profol GmbH, PT. Bhineka Tatamulya, Futamura Chemical, Schur Flexibles, Taghleef Industries, Panverta, Zhejiang Yuanda, Oben Group, Hubei Huishi, Mitsui Chemicals, Tri-Pack, Copol International, Jindal Poly Films, UFLEX, DDN, Polyplex, Takigawa Seisakusho, Achilles Corporation, Polibak |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |