What is Global Advanced Ceramics for Laser Products Market?

The Global Advanced Ceramics for Laser Products Market is a specialized segment within the broader ceramics industry, focusing on the development and application of advanced ceramic materials specifically designed for laser technologies. These ceramics are engineered to withstand extreme conditions, such as high temperatures and intense laser radiation, making them ideal for use in laser systems. The market encompasses a variety of ceramic materials, each offering unique properties that enhance the performance and durability of laser products. Advanced ceramics are crucial in improving the efficiency, precision, and longevity of laser devices used across various industries, including medical, industrial, and telecommunications. As technology continues to evolve, the demand for high-performance laser systems is increasing, driving the growth of this market. The global market for advanced ceramics in laser products is characterized by continuous innovation and development, as manufacturers strive to create materials that meet the ever-growing demands of modern laser applications. This market is expected to expand significantly as industries increasingly rely on laser technology for cutting-edge solutions. The advanced ceramics used in laser products are pivotal in ensuring that these systems operate at optimal levels, providing reliable and efficient performance in critical applications.

Silicon Carbide Ceramics, Silicon Nitride Ceramics, Oxide Ceramics, Others in the Global Advanced Ceramics for Laser Products Market:

Silicon Carbide Ceramics, Silicon Nitride Ceramics, Oxide Ceramics, and other types of ceramics play a significant role in the Global Advanced Ceramics for Laser Products Market. Silicon Carbide Ceramics are known for their exceptional hardness and thermal conductivity, making them ideal for high-power laser applications where heat dissipation is crucial. These ceramics are often used in laser components that require high thermal stability and resistance to wear and tear. Silicon Nitride Ceramics, on the other hand, are valued for their high fracture toughness and thermal shock resistance. These properties make them suitable for laser systems that operate under fluctuating temperatures and require materials that can withstand sudden changes without cracking or degrading. Oxide Ceramics, which include materials like alumina and zirconia, are widely used in laser products due to their excellent electrical insulation properties and resistance to chemical corrosion. These ceramics are often employed in laser components that require high dielectric strength and stability in harsh environments. Other advanced ceramics used in laser products include materials like aluminum nitride and boron carbide, each offering unique benefits that enhance the performance of laser systems. Aluminum nitride, for example, is prized for its high thermal conductivity and electrical insulation properties, making it suitable for use in laser substrates and heat sinks. Boron carbide, known for its extreme hardness and low density, is used in applications where weight reduction and wear resistance are critical. The choice of ceramic material in laser products depends on the specific requirements of the application, such as thermal management, mechanical strength, and chemical resistance. Manufacturers in the Global Advanced Ceramics for Laser Products Market are continually exploring new materials and processing techniques to develop ceramics that meet the evolving needs of laser technologies. This ongoing innovation is essential for maintaining the performance and reliability of laser systems in various industries. As the demand for advanced laser applications grows, the role of ceramics in enhancing the capabilities of these systems becomes increasingly important. The development of new ceramic materials and the refinement of existing ones are key factors driving the advancement of laser technologies and the expansion of the Global Advanced Ceramics for Laser Products Market.

Feedthroughs, Laser Reflectors, Laser Tubes, Laser Waveguides, Others in the Global Advanced Ceramics for Laser Products Market:

The usage of Global Advanced Ceramics for Laser Products Market in areas such as Feedthroughs, Laser Reflectors, Laser Tubes, Laser Waveguides, and others is integral to the functionality and efficiency of laser systems. Feedthroughs, which are components that allow electrical signals to pass through a barrier without compromising the barrier's integrity, benefit from advanced ceramics due to their excellent electrical insulation and thermal stability. These properties ensure that feedthroughs can operate reliably in high-temperature environments, maintaining the performance of laser systems. Laser Reflectors, which are used to direct and focus laser beams, require materials with high reflectivity and thermal resistance. Advanced ceramics provide the necessary durability and precision, ensuring that reflectors can withstand the intense energy of laser beams without degrading. Laser Tubes, which house the laser medium and facilitate the generation of laser light, benefit from ceramics that offer high thermal conductivity and chemical resistance. These properties help maintain the stability and efficiency of the laser tube, ensuring consistent laser output. Laser Waveguides, which guide the laser beam along a specific path, require materials with precise dimensional stability and low optical loss. Advanced ceramics provide the necessary structural integrity and optical clarity, ensuring that waveguides can efficiently transmit laser beams with minimal distortion. Other applications of advanced ceramics in laser products include components like laser nozzles and laser lenses, which benefit from the hardness, thermal resistance, and optical properties of ceramics. The use of advanced ceramics in these areas enhances the performance and longevity of laser systems, making them more reliable and efficient for various applications. As laser technologies continue to evolve, the demand for advanced ceramic components in these areas is expected to grow, driving further innovation and development in the Global Advanced Ceramics for Laser Products Market. The integration of advanced ceramics into laser systems is crucial for meeting the increasing demands of industries that rely on laser technology for precision, efficiency, and reliability.

Global Advanced Ceramics for Laser Products Market Outlook:

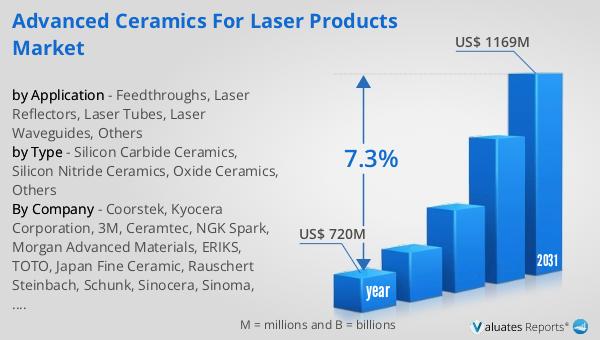

The global market for Advanced Ceramics for Laser Products was valued at $720 million in 2024, with projections indicating a growth to $1,169 million by 2031. This represents a compound annual growth rate (CAGR) of 7.3% over the forecast period. This growth is driven by the increasing demand for high-performance laser systems across various industries, including medical, industrial, and telecommunications. Advanced ceramics play a crucial role in enhancing the performance and durability of laser products, making them indispensable in modern laser technologies. The market's expansion is fueled by continuous innovation and development in ceramic materials, as manufacturers strive to meet the evolving needs of laser applications. The projected growth reflects the increasing reliance on laser technology for cutting-edge solutions, as well as the ongoing advancements in ceramic materials that enhance the capabilities of laser systems. As industries continue to adopt laser technologies for precision and efficiency, the demand for advanced ceramics in laser products is expected to rise, driving further growth in the market. The Global Advanced Ceramics for Laser Products Market is poised for significant expansion, as the integration of advanced ceramics into laser systems becomes increasingly important for meeting the demands of modern applications.

| Report Metric | Details |

| Report Name | Advanced Ceramics for Laser Products Market |

| Accounted market size in year | US$ 720 million |

| Forecasted market size in 2031 | US$ 1169 million |

| CAGR | 7.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Coorstek, Kyocera Corporation, 3M, Ceramtec, NGK Spark, Morgan Advanced Materials, ERIKS, TOTO, Japan Fine Ceramic, Rauschert Steinbach, Schunk, Sinocera, Sinoma, Chaozhou Three-Circle, Huamei, Shandong jinhongxin Material |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |