What is Global Wheel Loader Rock Bucket Market?

The Global Wheel Loader Rock Bucket Market is a specialized segment within the construction and heavy machinery industry, focusing on the production and distribution of rock buckets designed for wheel loaders. These rock buckets are essential attachments that enhance the functionality of wheel loaders, allowing them to efficiently scoop, lift, and transport heavy materials like rocks, gravel, and debris. The market encompasses a wide range of products tailored to different sizes and capacities, catering to various industrial needs. The demand for wheel loader rock buckets is driven by the growth in construction activities, mining operations, and infrastructure development worldwide. As urbanization and industrialization continue to expand, the need for efficient material handling solutions becomes increasingly critical. Manufacturers in this market are constantly innovating to improve the durability, efficiency, and versatility of their products, ensuring they meet the rigorous demands of different working environments. The market is characterized by a mix of global and regional players, each striving to capture a share of the growing demand. With advancements in technology and materials, the Global Wheel Loader Rock Bucket Market is poised for continued growth, adapting to the evolving needs of industries across the globe.

Small and Medium: <1m³, Large: >2m³ in the Global Wheel Loader Rock Bucket Market:

In the Global Wheel Loader Rock Bucket Market, the products are typically categorized based on their capacity, which directly influences their application and suitability for different tasks. Small and medium-sized buckets, with a capacity of less than 1 cubic meter, are designed for tasks that require precision and maneuverability. These buckets are ideal for smaller construction sites, landscaping projects, and urban environments where space is limited. Their compact size allows for easy navigation in tight spaces, making them a preferred choice for contractors working in densely populated areas. Despite their smaller size, these buckets are engineered to handle a variety of materials, from loose soil to compacted gravel, ensuring versatility in their application. On the other hand, large buckets with a capacity of more than 2 cubic meters are built for heavy-duty tasks that demand high efficiency and productivity. These buckets are commonly used in large-scale construction projects, mining operations, and quarries where the volume of material to be moved is substantial. The robust construction of these large buckets ensures they can withstand the harsh conditions often encountered in such environments, including abrasive materials and extreme weather. The choice between small, medium, and large buckets depends on several factors, including the nature of the project, the type of material being handled, and the operational constraints of the site. For instance, in a mining operation where large volumes of rock need to be transported quickly, a large bucket would be more suitable due to its capacity to move more material in a single scoop. Conversely, in a residential construction project where precision is key, a smaller bucket would be more appropriate. The versatility of wheel loader rock buckets is further enhanced by the availability of various designs and features that cater to specific needs. Some buckets are equipped with teeth or cutting edges to improve their ability to penetrate hard materials, while others may have reinforced sides to prevent wear and tear. Additionally, quick-attach systems allow for easy swapping of buckets, enabling operators to switch between different tasks without significant downtime. This adaptability is crucial in industries where time and efficiency are of the essence. As the Global Wheel Loader Rock Bucket Market continues to evolve, manufacturers are focusing on developing products that not only meet the current demands but also anticipate future needs. This includes incorporating advanced materials and technologies that enhance the performance and longevity of the buckets. For example, the use of high-strength steel and wear-resistant coatings can significantly extend the lifespan of a bucket, reducing the need for frequent replacements and lowering operational costs. Furthermore, the integration of smart technologies, such as sensors and telematics, is becoming increasingly common, providing operators with real-time data on bucket performance and maintenance needs. This information can be invaluable in optimizing the use of the equipment, ensuring it operates at peak efficiency and minimizing the risk of unexpected breakdowns. In conclusion, the Global Wheel Loader Rock Bucket Market offers a diverse range of products designed to meet the varying needs of different industries. Whether it's a small bucket for a landscaping project or a large bucket for a mining operation, the market provides solutions that enhance the capabilities of wheel loaders, making them indispensable tools in modern construction and material handling.

Mines, Quarries, Others in the Global Wheel Loader Rock Bucket Market:

The Global Wheel Loader Rock Bucket Market finds its applications in various sectors, with mines, quarries, and other industries being the primary areas of usage. In mining operations, wheel loader rock buckets are indispensable tools that facilitate the efficient handling of extracted materials. These buckets are designed to withstand the harsh conditions of mining sites, where they are used to scoop and transport large volumes of ore, rocks, and other materials. The durability and capacity of these buckets are crucial, as they directly impact the productivity and efficiency of mining operations. By enabling the quick and efficient movement of materials, wheel loader rock buckets help to streamline the mining process, reducing downtime and increasing output. In quarries, the role of wheel loader rock buckets is similarly vital. Quarries are sites where raw materials such as stone, gravel, and sand are extracted for use in construction and other industries. The rugged terrain and heavy materials found in quarries require equipment that can handle the demands of such environments. Wheel loader rock buckets are designed to meet these challenges, providing the strength and capacity needed to move large quantities of material efficiently. Their ability to handle abrasive materials without significant wear and tear makes them an essential component of quarry operations. Beyond mines and quarries, wheel loader rock buckets are also used in a variety of other industries. In construction, they are employed for tasks such as site preparation, material handling, and debris removal. The versatility of these buckets allows them to be used in different phases of construction projects, from initial groundwork to final site cleanup. In agriculture, wheel loader rock buckets are used for tasks such as moving soil, feed, and other materials, contributing to the efficiency of farming operations. The adaptability of wheel loader rock buckets is further enhanced by the availability of different designs and features that cater to specific needs. For example, some buckets are equipped with teeth or cutting edges to improve their ability to penetrate hard materials, while others may have reinforced sides to prevent wear and tear. Additionally, quick-attach systems allow for easy swapping of buckets, enabling operators to switch between different tasks without significant downtime. This adaptability is crucial in industries where time and efficiency are of the essence. As the Global Wheel Loader Rock Bucket Market continues to evolve, manufacturers are focusing on developing products that not only meet the current demands but also anticipate future needs. This includes incorporating advanced materials and technologies that enhance the performance and longevity of the buckets. For example, the use of high-strength steel and wear-resistant coatings can significantly extend the lifespan of a bucket, reducing the need for frequent replacements and lowering operational costs. Furthermore, the integration of smart technologies, such as sensors and telematics, is becoming increasingly common, providing operators with real-time data on bucket performance and maintenance needs. This information can be invaluable in optimizing the use of the equipment, ensuring it operates at peak efficiency and minimizing the risk of unexpected breakdowns. In conclusion, the Global Wheel Loader Rock Bucket Market plays a critical role in various industries, providing the tools needed to efficiently handle and transport materials. Whether in mines, quarries, or other sectors, these buckets enhance the capabilities of wheel loaders, making them indispensable tools in modern material handling.

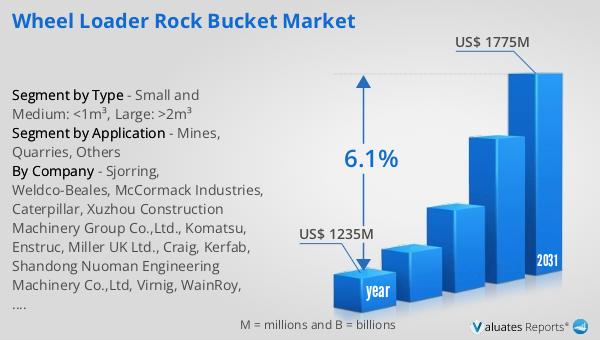

Global Wheel Loader Rock Bucket Market Outlook:

The global market for Wheel Loader Rock Buckets was valued at $1,235 million in 2024 and is anticipated to expand to a revised size of $1,775 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.1% over the forecast period. This growth trajectory underscores the increasing demand for efficient material handling solutions across various industries, driven by the expansion of construction activities, mining operations, and infrastructure development worldwide. As urbanization and industrialization continue to accelerate, the need for robust and versatile equipment like wheel loader rock buckets becomes more pronounced. The market's growth is further supported by technological advancements and innovations in product design, which enhance the performance and durability of these buckets. Manufacturers are focusing on developing products that not only meet the current demands but also anticipate future needs, incorporating advanced materials and technologies to improve efficiency and longevity. The integration of smart technologies, such as sensors and telematics, is also becoming increasingly common, providing operators with real-time data on bucket performance and maintenance needs. This information can be invaluable in optimizing the use of the equipment, ensuring it operates at peak efficiency and minimizing the risk of unexpected breakdowns. As the market continues to evolve, it presents significant opportunities for both established players and new entrants to capture a share of the growing demand for wheel loader rock buckets.

| Report Metric | Details |

| Report Name | Wheel Loader Rock Bucket Market |

| Accounted market size in year | US$ 1235 million |

| Forecasted market size in 2031 | US$ 1775 million |

| CAGR | 6.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Sjorring, Weldco-Beales, McCormack Industries, Caterpillar, Xuzhou Construction Machinery Group Co.,Ltd., Komatsu, Enstruc, Miller UK Ltd., Craig, Kerfab, Shandong Nuoman Engineering Machinery Co.,Ltd, Virnig, WainRoy, VOLVOCE, Omnia Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |