What is Global PDC Coring Drill Bits Market?

The Global PDC Coring Drill Bits Market refers to the worldwide industry focused on the production and distribution of Polycrystalline Diamond Compact (PDC) coring drill bits. These specialized tools are essential in the drilling industry, particularly for extracting core samples from the earth. PDC coring drill bits are known for their durability and efficiency, as they are designed to withstand high temperatures and pressures encountered during drilling operations. The market encompasses various sectors, including oil and gas exploration, mining, and construction, where these drill bits are extensively used. The demand for PDC coring drill bits is driven by the need for efficient drilling solutions that can reduce operational costs and improve productivity. As industries continue to expand their exploration and extraction activities, the market for PDC coring drill bits is expected to grow, offering opportunities for manufacturers and suppliers to innovate and meet the evolving needs of their customers. The market is characterized by technological advancements, competitive pricing, and a focus on sustainability, as companies strive to develop eco-friendly drilling solutions. Overall, the Global PDC Coring Drill Bits Market plays a crucial role in supporting various industries by providing reliable and efficient drilling tools.

Matrix Body, Steel Body, Others in the Global PDC Coring Drill Bits Market:

In the Global PDC Coring Drill Bits Market, there are primarily three types of drill bits based on their body material: Matrix Body, Steel Body, and Others. Each type has its unique characteristics and applications, catering to different drilling needs and conditions. Matrix Body PDC coring drill bits are made from a composite material that combines tungsten carbide with a metallic binder. This construction gives them excellent wear resistance and durability, making them suitable for drilling in hard and abrasive formations. The matrix body provides a strong foundation for the PDC cutters, allowing them to maintain their sharpness and cutting efficiency over extended periods. These drill bits are often used in challenging drilling environments where longevity and performance are critical. On the other hand, Steel Body PDC coring drill bits are constructed from high-strength steel, offering greater flexibility and toughness compared to matrix body bits. The steel body allows for more aggressive drilling, making these bits ideal for softer formations where speed and efficiency are prioritized. Steel body bits are also easier to repair and maintain, providing cost-effective solutions for drilling operations. The "Others" category in the Global PDC Coring Drill Bits Market includes hybrid designs and specialized bits that combine features of both matrix and steel body bits or incorporate innovative materials and technologies. These bits are designed to address specific drilling challenges and optimize performance in unique conditions. For instance, some hybrid bits may feature a steel body with a matrix face, offering a balance between durability and flexibility. Others may incorporate advanced materials like thermally stable polycrystalline (TSP) diamonds to enhance cutting efficiency and heat resistance. The choice between matrix body, steel body, and other types of PDC coring drill bits depends on various factors, including the geological conditions, drilling objectives, and cost considerations. Manufacturers in the Global PDC Coring Drill Bits Market continuously innovate to improve the performance and versatility of these tools, ensuring they meet the diverse needs of the drilling industry. As technology advances, the development of new materials and designs is expected to further enhance the capabilities of PDC coring drill bits, providing more efficient and sustainable solutions for drilling operations worldwide.

Tunnels, Mines, Natural Gas, Petroleum, Others in the Global PDC Coring Drill Bits Market:

The Global PDC Coring Drill Bits Market finds extensive usage across various sectors, including tunnels, mines, natural gas, petroleum, and others. In tunnel construction, PDC coring drill bits are essential for creating precise and efficient boreholes. The durability and cutting efficiency of these bits make them ideal for drilling through hard rock formations, ensuring the stability and safety of tunnel structures. In mining operations, PDC coring drill bits are used to extract core samples that provide valuable information about the mineral composition and geological conditions of the site. This data is crucial for planning and optimizing mining activities, as well as assessing the feasibility of resource extraction. The ability of PDC bits to maintain their cutting performance in abrasive and challenging environments makes them a preferred choice in the mining industry. In the natural gas sector, PDC coring drill bits play a vital role in exploration and production activities. These bits are used to drill wells that access natural gas reserves, enabling efficient extraction and production. The high-temperature and high-pressure conditions encountered in natural gas drilling require robust and reliable tools, making PDC coring drill bits an essential component of the drilling process. Similarly, in the petroleum industry, PDC coring drill bits are used for drilling oil wells and extracting core samples that provide insights into the reservoir's characteristics. The efficiency and durability of PDC bits contribute to reducing drilling time and costs, enhancing the overall productivity of oil exploration and production operations. Beyond these primary sectors, PDC coring drill bits are also used in various other applications, such as geothermal energy exploration, water well drilling, and construction projects. In geothermal energy, these bits are used to drill wells that access heat from the earth's core, providing a sustainable energy source. In water well drilling, PDC bits ensure efficient and precise drilling, facilitating access to underground water resources. In construction, these bits are used for foundation drilling and other structural applications, where precision and reliability are paramount. Overall, the versatility and performance of PDC coring drill bits make them indispensable tools across multiple industries, supporting efficient and sustainable resource extraction and infrastructure development.

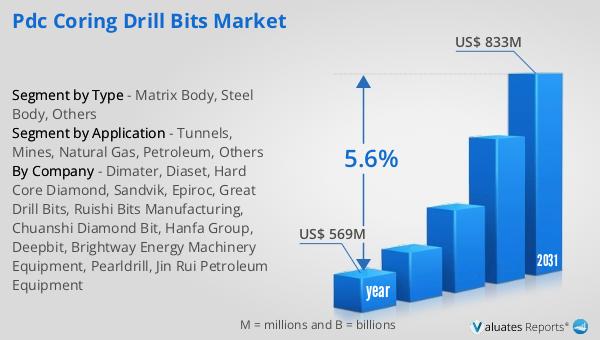

Global PDC Coring Drill Bits Market Outlook:

The global market for PDC Coring Drill Bits was valued at $569 million in 2024, with projections indicating it will expand to a revised size of $833 million by 2031. This growth represents a compound annual growth rate (CAGR) of 5.6% over the forecast period. This upward trend highlights the increasing demand for efficient and durable drilling solutions across various industries. The market's expansion is driven by the need for advanced drilling technologies that can enhance productivity and reduce operational costs. As industries such as oil and gas, mining, and construction continue to grow, the demand for PDC coring drill bits is expected to rise, offering opportunities for manufacturers to innovate and meet the evolving needs of their customers. The market is characterized by technological advancements, competitive pricing, and a focus on sustainability, as companies strive to develop eco-friendly drilling solutions. The growth of the Global PDC Coring Drill Bits Market reflects the ongoing efforts to improve drilling efficiency and support the sustainable development of natural resources. As the market continues to evolve, manufacturers and suppliers are expected to focus on enhancing the performance and versatility of PDC coring drill bits, ensuring they remain a critical component of the drilling industry.

| Report Metric | Details |

| Report Name | PDC Coring Drill Bits Market |

| Accounted market size in year | US$ 569 million |

| Forecasted market size in 2031 | US$ 833 million |

| CAGR | 5.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dimater, Diaset, Hard Core Diamond, Sandvik, Epiroc, Great Drill Bits, Ruishi Bits Manufacturing, Chuanshi Diamond Bit, Hanfa Group, Deepbit, Brightway Energy Machinery Equipment, Pearldrill, Jin Rui Petroleum Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |