What is Global CMP Pads Conditioning Disk Market?

The Global CMP Pads Conditioning Disk Market is a specialized segment within the semiconductor industry, focusing on the tools used for chemical mechanical planarization (CMP). CMP is a critical process in semiconductor manufacturing, where it is used to smooth and flatten the surfaces of wafers. The conditioning disks are essential components in this process, as they help maintain the effectiveness and longevity of the CMP pads. These disks work by conditioning the surface of the CMP pads, ensuring they remain effective in polishing wafers to the required specifications. The market for these disks is driven by the increasing demand for semiconductors, which are integral to a wide range of electronic devices. As technology advances, the need for more precise and efficient manufacturing processes grows, further fueling the demand for CMP pads conditioning disks. The market is characterized by continuous innovation, with manufacturers striving to develop disks that offer better performance, longer life, and greater efficiency. This market is crucial for the semiconductor industry, as it directly impacts the quality and performance of the final electronic products.

Conventional Pad Conditioners, CVD Diamond Pad Conditioners in the Global CMP Pads Conditioning Disk Market:

Conventional pad conditioners and CVD diamond pad conditioners are two primary types of conditioning disks used in the Global CMP Pads Conditioning Disk Market. Conventional pad conditioners are typically made from materials like silicon carbide or other abrasives bonded to a substrate. These conditioners are designed to mechanically abrade the surface of the CMP pads, maintaining their texture and effectiveness. They are generally more affordable than their CVD diamond counterparts, making them a popular choice for many manufacturers. However, they may wear out more quickly and require more frequent replacement, which can lead to increased downtime and maintenance costs. On the other hand, CVD diamond pad conditioners are made using chemical vapor deposition (CVD) to create a diamond coating on the conditioning disk. This diamond coating provides superior hardness and durability, allowing the conditioner to last longer and maintain the CMP pad's effectiveness over a more extended period. The use of diamond also ensures a more consistent conditioning process, which can lead to better wafer quality and reduced defect rates. While CVD diamond pad conditioners are more expensive upfront, their longer lifespan and improved performance can result in cost savings over time. The choice between conventional and CVD diamond pad conditioners often depends on the specific needs and budget of the semiconductor manufacturer. Some may opt for the lower initial cost of conventional conditioners, while others may prioritize the long-term benefits of CVD diamond conditioners. As the semiconductor industry continues to evolve, the demand for more advanced and efficient conditioning solutions is likely to grow, driving further innovation in both conventional and CVD diamond pad conditioners.

300mm Wafer, 200mm Wafer, Others in the Global CMP Pads Conditioning Disk Market:

The Global CMP Pads Conditioning Disk Market finds its application in various wafer sizes, including 300mm wafers, 200mm wafers, and others. The 300mm wafer segment is particularly significant, as it represents the current standard in semiconductor manufacturing. These larger wafers allow for more chips to be produced per wafer, increasing efficiency and reducing costs. CMP pads conditioning disks play a crucial role in ensuring the quality and consistency of these wafers, as they help maintain the effectiveness of the CMP pads used in the polishing process. The demand for 300mm wafers is driven by the need for more powerful and efficient electronic devices, which require advanced semiconductor technology. The 200mm wafer segment, while not as prominent as the 300mm segment, still holds a significant share of the market. These wafers are often used in the production of older or less advanced semiconductor technologies, where the cost savings of using smaller wafers can be beneficial. CMP pads conditioning disks are equally important in this segment, as they help ensure the quality and performance of the wafers. The "others" category includes wafers of various sizes, often used in specialized or niche applications. These may include smaller wafers used in research and development or larger wafers used in specific industrial applications. Regardless of the size, CMP pads conditioning disks are essential for maintaining the quality and consistency of the wafers, ensuring they meet the required specifications. As the semiconductor industry continues to advance, the demand for CMP pads conditioning disks across all wafer sizes is expected to grow, driven by the need for more efficient and effective manufacturing processes.

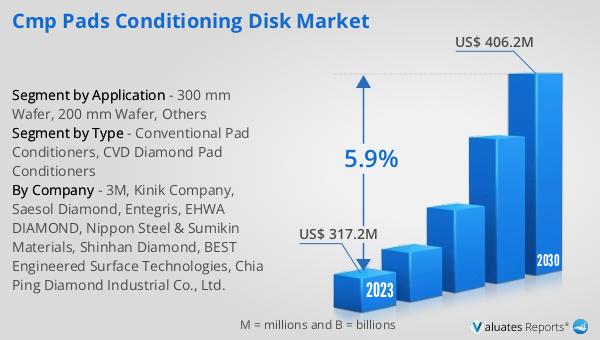

Global CMP Pads Conditioning Disk Market Outlook:

In 2024, the global market for CMP Pads Conditioning Disks was valued at approximately $320 million. This market is anticipated to expand significantly, reaching an estimated size of $506 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.5% over the forecast period. This upward trend is indicative of the increasing demand for advanced semiconductor manufacturing processes, which require high-quality CMP pads conditioning disks to ensure the effectiveness and longevity of CMP pads. The market's growth is driven by several factors, including the rising demand for semiconductors in various electronic devices, the need for more efficient manufacturing processes, and the continuous innovation in conditioning disk technology. As the semiconductor industry evolves, the importance of CMP pads conditioning disks in maintaining wafer quality and consistency becomes even more critical. This market outlook highlights the significant opportunities for manufacturers and suppliers of CMP pads conditioning disks, as they strive to meet the growing demand for more advanced and efficient solutions. The projected growth in this market underscores the vital role that CMP pads conditioning disks play in the semiconductor manufacturing process, as they directly impact the quality and performance of the final electronic products.

| Report Metric | Details |

| Report Name | CMP Pads Conditioning Disk Market |

| Accounted market size in year | US$ 320 million |

| Forecasted market size in 2031 | US$ 506 million |

| CAGR | 6.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | 3M, Kinik Company, Saesol Diamond, Entegris, EHWA DIAMOND, Nippon Steel Chemical & Material, Shinhan Diamond, Abrasive Technology, BEST Engineering Surface Technologies, Xiamen Jiapin Diamond Industry |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |