What is Global Chemical Injection Skids Market?

The Global Chemical Injection Skids Market is a specialized segment within the broader industrial equipment sector, focusing on the design, manufacture, and deployment of chemical injection systems. These skids are essentially pre-packaged units that include pumps, tanks, piping, and control systems, all mounted on a single frame. They are used to inject precise amounts of chemicals into a system or process to achieve desired outcomes, such as preventing corrosion, reducing foam, or separating emulsions. The market for these skids is driven by industries such as oil and gas, petrochemicals, water treatment, and energy, where the precise and controlled addition of chemicals is critical for operational efficiency and safety. The demand for chemical injection skids is influenced by factors such as the growth of these industries, technological advancements in skid design, and the increasing need for automation and precision in chemical processes. As industries continue to expand and modernize, the need for reliable and efficient chemical injection systems is expected to grow, making this market an essential component of industrial operations worldwide.

Antifoam Chemical Injection Skids, Corrosion Inhibitor Chemical Injection Skids, Demulsifying Chemical Injection Skids, Scale Inhibitor Chemical Injection Skids, Others in the Global Chemical Injection Skids Market:

Antifoam Chemical Injection Skids are designed to inject antifoaming agents into industrial processes to prevent the formation of foam, which can disrupt operations and reduce efficiency. Foam can cause problems such as overflow, reduced heat transfer, and inaccurate level measurements. By using antifoam injection skids, industries can maintain smooth operations and improve process efficiency. Corrosion Inhibitor Chemical Injection Skids are crucial in industries where metal equipment is exposed to corrosive substances. These skids inject corrosion inhibitors into the system to protect metal surfaces from corrosion, thereby extending the lifespan of equipment and reducing maintenance costs. Demulsifying Chemical Injection Skids are used to separate emulsions, which are mixtures of two immiscible liquids, such as oil and water. In the oil and gas industry, demulsifiers are injected to break down emulsions, allowing for the efficient separation of oil and water, which is essential for refining processes. Scale Inhibitor Chemical Injection Skids are employed to prevent the formation of scale, which is a hard, mineral deposit that can clog pipes and reduce the efficiency of heat exchangers. By injecting scale inhibitors, industries can maintain optimal flow rates and heat transfer efficiency. Other types of chemical injection skids include those used for injecting biocides, oxygen scavengers, and pH adjusters, each serving a specific purpose in maintaining the integrity and efficiency of industrial processes. These skids are designed to be highly reliable and precise, ensuring that the correct amount of chemical is injected at the right time, which is critical for achieving the desired outcome. The versatility and adaptability of chemical injection skids make them an indispensable tool in various industries, allowing for the customization of chemical treatment processes to meet specific operational needs. As industries continue to evolve and face new challenges, the demand for advanced chemical injection skids that can handle a wide range of chemicals and operating conditions is expected to increase.

Petrochemicals, Chemical, Energy & Power, Oil & Gas, Water Treatment, Others in the Global Chemical Injection Skids Market:

The Global Chemical Injection Skids Market finds extensive application across various industries, each with its unique requirements and challenges. In the petrochemical industry, chemical injection skids are used to enhance the efficiency and safety of chemical processes. They are employed to inject catalysts, inhibitors, and other chemicals that facilitate reactions and prevent issues such as corrosion and fouling. In the chemical industry, these skids are used to ensure precise dosing of chemicals in manufacturing processes, which is critical for product quality and consistency. The energy and power sector utilizes chemical injection skids to maintain the efficiency of power generation systems. For instance, they are used to inject chemicals that prevent scale formation in boilers and cooling systems, ensuring optimal heat transfer and reducing maintenance costs. In the oil and gas industry, chemical injection skids play a vital role in upstream, midstream, and downstream operations. They are used to inject demulsifiers, corrosion inhibitors, and other chemicals that enhance oil recovery, protect pipelines, and improve refining processes. Water treatment facilities use chemical injection skids to inject coagulants, flocculants, and disinfectants, ensuring the safe and efficient treatment of water for industrial and municipal use. Other industries, such as pharmaceuticals and food and beverage, also rely on chemical injection skids for precise chemical dosing in their processes. The versatility and precision of chemical injection skids make them an essential component in these industries, enabling them to meet regulatory requirements, improve operational efficiency, and reduce costs. As industries continue to face increasing pressure to improve efficiency and sustainability, the demand for advanced chemical injection skids that offer greater precision, automation, and adaptability is expected to grow.

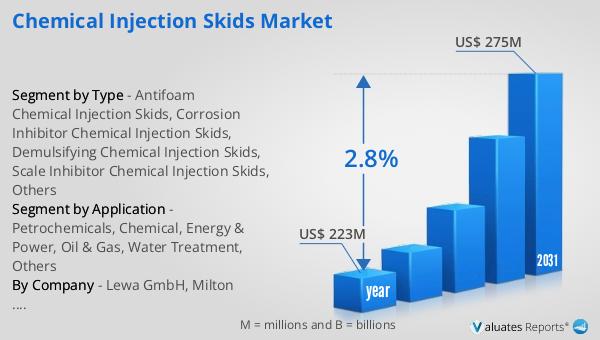

Global Chemical Injection Skids Market Outlook:

In 2024, the global market for Chemical Injection Skids was valued at approximately $223 million, with projections indicating a growth to around $275 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.8% over the forecast period. The top ten players in this market are significant contributors, accounting for about 60% of the total revenue in 2024. North America emerged as the leading region, capturing over 32% of the global market revenue in 2024. Following closely, the Middle East and Africa region held a substantial share, contributing approximately 30% to the market revenue in the same year. Among the key players, Lewa GmbH stood out as the largest manufacturer, with its revenue exceeding 13% of the global market in 2024. This market outlook highlights the competitive landscape and regional dynamics within the Chemical Injection Skids Market, underscoring the significant role of major players and the dominance of specific regions in driving market growth. The steady growth trajectory and regional contributions reflect the increasing demand for chemical injection solutions across various industries, driven by the need for precision, efficiency, and reliability in chemical processes.

| Report Metric | Details |

| Report Name | Chemical Injection Skids Market |

| Accounted market size in year | US$ 223 million |

| Forecasted market size in 2031 | US$ 275 million |

| CAGR | 2.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Lewa GmbH, Milton Roy Europe, Doedijns Group International (DGI), Petronash, Proserv Group, IDEX, Seko, SPX FLOW, Petrak Industries, MOWE Marine and Offshore, Metalfab Middle East FZ LLC., AES Arabia, Santacc Energy, Shenzhen Fluid Science & Technology, Zhejiang Ailipu Technology, Jiangsu Feiyue Pump |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |