What is Global Automotive Alloy Wheel Market?

The Global Automotive Alloy Wheel Market is a dynamic and evolving sector within the automotive industry, characterized by its focus on the production and distribution of alloy wheels. Alloy wheels are made from a blend of aluminum or magnesium metals, offering a lightweight yet strong alternative to traditional steel wheels. This market is driven by the increasing demand for vehicles that are not only efficient but also aesthetically appealing. Alloy wheels contribute to improved vehicle performance by reducing the overall weight, which enhances fuel efficiency and handling. Additionally, they offer better heat conduction, which helps in dissipating heat from the brakes, thereby improving braking performance. The market is influenced by factors such as technological advancements, consumer preferences for stylish and high-performance vehicles, and the growing automotive industry worldwide. As manufacturers continue to innovate and develop new designs and materials, the Global Automotive Alloy Wheel Market is expected to expand, catering to both the luxury and mass-market segments. The market's growth is also supported by the rising trend of vehicle customization, where consumers seek unique and personalized wheel designs to enhance the look and feel of their vehicles.

Casting, Forging, Other in the Global Automotive Alloy Wheel Market:

In the Global Automotive Alloy Wheel Market, the manufacturing processes primarily involve casting, forging, and other methods, each offering distinct advantages and characteristics. Casting is one of the most common methods used in the production of alloy wheels. It involves pouring molten metal into a mold to form the wheel. This process is cost-effective and allows for the creation of complex designs, making it popular for mass production. There are different types of casting, such as gravity casting, low-pressure casting, and high-pressure die casting, each varying in terms of cost, quality, and production speed. Gravity casting is the simplest form, where molten metal is poured into a mold using gravity. Low-pressure casting involves forcing the molten metal into the mold under low pressure, resulting in a denser and stronger wheel. High-pressure die casting, on the other hand, uses high pressure to inject the metal into the mold, producing wheels with excellent surface finish and dimensional accuracy. Forging is another prominent method used in the production of alloy wheels. It involves shaping the metal using compressive forces, typically with a hydraulic press. Forged wheels are known for their superior strength and lightweight properties, as the forging process aligns the metal's grain structure, enhancing its mechanical properties. This method is more expensive than casting but offers significant performance benefits, making it popular in high-performance and luxury vehicles. Forged wheels are often preferred by automotive enthusiasts and professionals who prioritize performance and durability. Other methods in the production of alloy wheels include flow forming and rotary forging. Flow forming is a hybrid process that combines elements of casting and forging. It involves casting a wheel blank and then using rollers to stretch and compress the material, resulting in a wheel that is lighter and stronger than a traditional cast wheel. Rotary forging, similar to flow forming, involves spinning the wheel blank while applying pressure to shape it. This process enhances the wheel's strength and reduces its weight, offering a balance between cost and performance. Each of these manufacturing methods plays a crucial role in the Global Automotive Alloy Wheel Market, catering to different segments and consumer preferences. While casting remains the most widely used method due to its cost-effectiveness and design flexibility, forging and other advanced techniques are gaining popularity for their performance advantages. As the market continues to evolve, manufacturers are likely to explore new technologies and processes to meet the growing demand for high-quality, lightweight, and aesthetically pleasing alloy wheels.

Passenger Vehicle, Commercial Vehicle in the Global Automotive Alloy Wheel Market:

The usage of alloy wheels in the Global Automotive Alloy Wheel Market spans across various vehicle types, primarily focusing on passenger vehicles and commercial vehicles. In passenger vehicles, alloy wheels are highly sought after for their aesthetic appeal and performance benefits. They are often used as a selling point by manufacturers to attract consumers looking for stylish and modern vehicles. The lightweight nature of alloy wheels contributes to improved fuel efficiency, which is a significant consideration for many car buyers. Additionally, the enhanced heat dissipation properties of alloy wheels improve braking performance, providing a safer driving experience. In the realm of commercial vehicles, alloy wheels are increasingly being adopted due to their durability and performance advantages. Commercial vehicles, such as trucks and buses, require wheels that can withstand heavy loads and long distances. Alloy wheels, with their superior strength-to-weight ratio, offer a reliable solution for these demands. They help in reducing the overall weight of the vehicle, leading to better fuel economy and reduced emissions, which are critical factors for fleet operators looking to minimize operational costs and environmental impact. Moreover, the use of alloy wheels in commercial vehicles can enhance the vehicle's resale value, making them an attractive investment for businesses. The versatility of alloy wheels allows them to be used in a wide range of vehicle models, from compact cars to large commercial trucks. This adaptability is a key driver of their popularity in the automotive market. As consumer preferences continue to shift towards vehicles that offer both performance and style, the demand for alloy wheels in both passenger and commercial vehicles is expected to grow. Manufacturers are likely to continue innovating and developing new designs and materials to meet this demand, further solidifying the role of alloy wheels in the global automotive industry.

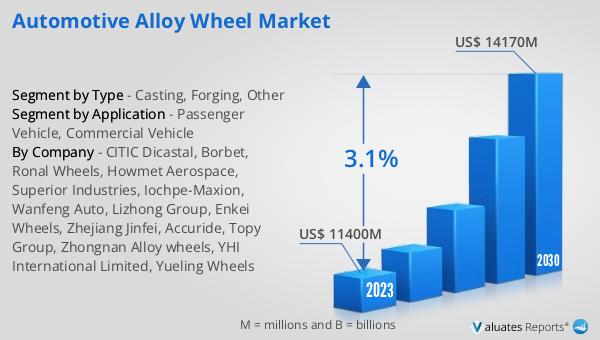

Global Automotive Alloy Wheel Market Outlook:

The global market for automotive alloy wheels was valued at $18,613 million in 2024, and it is anticipated to grow to a revised size of $21,837 million by 2031. This growth represents a compound annual growth rate (CAGR) of 2.4% over the forecast period. This steady growth trajectory underscores the increasing demand for alloy wheels across various segments of the automotive industry. The market's expansion is driven by several factors, including the rising popularity of lightweight and fuel-efficient vehicles, advancements in manufacturing technologies, and the growing trend of vehicle customization. As consumers become more conscious of fuel efficiency and environmental impact, the demand for alloy wheels, which contribute to reduced vehicle weight and improved performance, is expected to rise. Additionally, the aesthetic appeal of alloy wheels makes them a popular choice for consumers looking to enhance the appearance of their vehicles. The market's growth is also supported by the increasing production and sales of vehicles worldwide, particularly in emerging economies where the automotive industry is experiencing rapid expansion. As manufacturers continue to innovate and develop new designs and materials, the Global Automotive Alloy Wheel Market is poised for sustained growth, catering to the evolving needs and preferences of consumers.

| Report Metric | Details |

| Report Name | Automotive Alloy Wheel Market |

| Accounted market size in year | US$ 18613 million |

| Forecasted market size in 2031 | US$ 21837 million |

| CAGR | 2.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | CITIC Dicastal, Superior Industries, Iochpe-Maxion, Ronal Wheels, Borbet, Howmet Aerospace, Lizhong Group, Wanfeng Auto, Zhejiang Jinfei, Topy Group, Enkei Wheels, Accuride, Yueling Wheels, YHI, Zhongnan Aluminum Wheels, JC Forged, Wheels India, Otto Fuchs, Pomlead, Zeroneal |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |