What is Global Wafer Dicing Surfactant Market?

The Global Wafer Dicing Surfactant Market is a specialized segment within the broader semiconductor industry, focusing on the production and application of surfactants used in the wafer dicing process. Wafer dicing is a critical step in semiconductor manufacturing, where silicon wafers are cut into individual chips or dies. Surfactants play a vital role in this process by reducing surface tension, ensuring clean cuts, and preventing damage to the delicate silicon structures. These surfactants help in minimizing defects and improving the yield of usable chips, which is crucial for maintaining the efficiency and cost-effectiveness of semiconductor production. The market for wafer dicing surfactants is driven by the increasing demand for semiconductors across various industries, including consumer electronics, automotive, and telecommunications. As technology advances and the need for smaller, more powerful electronic devices grows, the demand for high-quality wafer dicing surfactants is expected to rise. This market is characterized by continuous innovation, with manufacturers striving to develop surfactants that offer better performance, environmental sustainability, and cost-effectiveness. The global wafer dicing surfactant market is a dynamic and essential component of the semiconductor supply chain, supporting the production of the advanced electronic devices that power our modern world.

Acetylenic Diol Type, Primary Alcohol Ethoxylates Type, Phenyl Ethoxylates Type, Others in the Global Wafer Dicing Surfactant Market:

The Global Wafer Dicing Surfactant Market is composed of various types of surfactants, each with unique properties and applications. One of the primary types is the Acetylenic Diol Type surfactant. These surfactants are known for their excellent wetting properties and ability to reduce surface tension significantly. Acetylenic diol surfactants are particularly effective in applications where precise control over the liquid's behavior is required, such as in the wafer dicing process. They help in achieving clean cuts and reducing the risk of chipping or cracking the silicon wafers. Their chemical structure allows them to perform well under the high-stress conditions of semiconductor manufacturing, making them a popular choice among manufacturers. Another important type is the Primary Alcohol Ethoxylates Type surfactant. These surfactants are derived from natural alcohols and are known for their biodegradability and low toxicity. They are used in wafer dicing for their ability to provide excellent cleaning and wetting properties. Primary alcohol ethoxylates are effective in removing debris and contaminants from the wafer surface, ensuring a clean and smooth cut. Their environmental friendliness makes them an attractive option for manufacturers looking to reduce their ecological footprint. Phenyl Ethoxylates Type surfactants are another category used in the wafer dicing process. These surfactants are characterized by their aromatic structure, which provides unique wetting and dispersing properties. Phenyl ethoxylates are particularly effective in applications where high-temperature stability is required, as they can maintain their performance under extreme conditions. They are used in wafer dicing to ensure precise cuts and minimize the risk of defects. The aromatic nature of these surfactants also contributes to their ability to interact with various materials, making them versatile in different manufacturing environments. In addition to these primary types, there are other surfactants used in the wafer dicing process, each with specific properties tailored to meet the demands of different applications. These may include non-ionic, anionic, or cationic surfactants, each offering unique benefits in terms of wetting, dispersing, and cleaning capabilities. The choice of surfactant depends on various factors, including the type of wafer material, the dicing method used, and the specific requirements of the manufacturing process. Manufacturers often work closely with surfactant suppliers to develop customized solutions that meet their specific needs, ensuring optimal performance and efficiency in the wafer dicing process. The diversity of surfactants available in the Global Wafer Dicing Surfactant Market reflects the complexity and precision required in semiconductor manufacturing. As technology continues to evolve, the demand for advanced surfactants that can meet the stringent requirements of modern electronics production is expected to grow. This ongoing innovation and development in surfactant technology are crucial for supporting the advancement of the semiconductor industry and the production of cutting-edge electronic devices.

Semiconductor Manufacturing, Consumer Electronics, Automotive Electronics, Others in the Global Wafer Dicing Surfactant Market:

The Global Wafer Dicing Surfactant Market plays a crucial role in various industries, particularly in semiconductor manufacturing, consumer electronics, automotive electronics, and other sectors. In semiconductor manufacturing, wafer dicing surfactants are essential for ensuring the precision and quality of the dicing process. The surfactants help in reducing surface tension, allowing for cleaner cuts and minimizing the risk of damage to the delicate silicon wafers. This is critical in producing high-quality semiconductor chips that meet the stringent requirements of modern electronic devices. The use of surfactants in this process helps in improving yield and reducing waste, which is vital for maintaining the cost-effectiveness and efficiency of semiconductor production. In the consumer electronics industry, wafer dicing surfactants are used to support the production of a wide range of devices, including smartphones, tablets, laptops, and other personal electronics. The demand for smaller, more powerful, and energy-efficient devices drives the need for high-quality semiconductor chips, which in turn requires precise and efficient wafer dicing processes. Surfactants play a key role in achieving the level of precision needed to produce the tiny, intricate components used in these devices. By ensuring clean cuts and minimizing defects, surfactants help manufacturers meet the high standards of quality and performance expected by consumers. The automotive electronics sector also relies heavily on wafer dicing surfactants. As vehicles become increasingly equipped with advanced electronic systems, the demand for high-quality semiconductor components continues to grow. These components are used in various applications, including engine control units, infotainment systems, advanced driver-assistance systems (ADAS), and more. The precision and quality of the wafer dicing process are critical in producing the reliable and durable semiconductor chips needed for these applications. Surfactants help in achieving the necessary level of precision and quality, ensuring that the electronic components used in vehicles meet the rigorous standards of the automotive industry. Beyond these primary sectors, wafer dicing surfactants are also used in other industries where semiconductor components are essential. This includes telecommunications, healthcare, and industrial applications, among others. In each of these sectors, the demand for high-quality semiconductor chips drives the need for efficient and precise wafer dicing processes. Surfactants play a vital role in supporting these processes, helping manufacturers produce the advanced electronic components needed to power a wide range of technologies. The versatility and effectiveness of wafer dicing surfactants make them an indispensable part of the semiconductor manufacturing process, supporting the production of the cutting-edge electronic devices that are integral to our modern world.

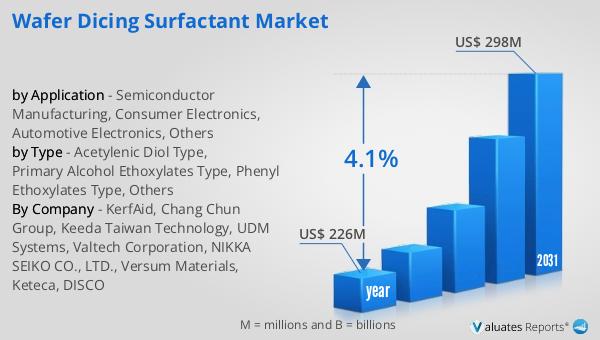

Global Wafer Dicing Surfactant Market Outlook:

In 2024, the global market for Wafer Dicing Surfactant was valued at approximately $226 million. Looking ahead, this market is anticipated to expand, reaching an estimated size of $298 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 4.1% over the forecast period. The steady increase in market size reflects the rising demand for semiconductor components across various industries, including consumer electronics, automotive, and telecommunications. As technology continues to advance, the need for high-quality wafer dicing surfactants becomes increasingly critical. These surfactants play a vital role in ensuring the precision and efficiency of the wafer dicing process, which is essential for producing the advanced semiconductor chips that power modern electronic devices. The projected growth of the Wafer Dicing Surfactant Market underscores the importance of these materials in supporting the semiconductor industry's ongoing innovation and development. As manufacturers strive to meet the demands of a rapidly evolving technological landscape, the need for effective and reliable surfactants will continue to drive market expansion. This growth not only highlights the significance of wafer dicing surfactants in the semiconductor supply chain but also emphasizes their role in enabling the production of cutting-edge electronic devices that are integral to our daily lives.

| Report Metric | Details |

| Report Name | Wafer Dicing Surfactant Market |

| Accounted market size in year | US$ 226 million |

| Forecasted market size in 2031 | US$ 298 million |

| CAGR | 4.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KerfAid, Chang Chun Group, Keeda Taiwan Technology, UDM Systems, Valtech Corporation, NIKKA SEIKO CO., LTD., Versum Materials, Keteca, DISCO |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |