What is Global DC Electric Arc Furnaces Market?

The Global DC Electric Arc Furnaces Market refers to the worldwide industry focused on the production and utilization of Direct Current (DC) electric arc furnaces. These furnaces are essential in the steelmaking process, where they are used to melt scrap metal and convert it into liquid steel. Unlike traditional alternating current (AC) furnaces, DC electric arc furnaces offer several advantages, including improved energy efficiency, reduced electrode consumption, and lower operational costs. The market for these furnaces is driven by the growing demand for steel across various industries, such as construction, automotive, and manufacturing. Additionally, the push for more sustainable and environmentally friendly production methods has led to increased adoption of DC electric arc furnaces, as they produce fewer emissions compared to their AC counterparts. The market is characterized by technological advancements, with manufacturers continuously innovating to enhance furnace performance and efficiency. As industries worldwide seek to optimize their production processes and reduce their carbon footprint, the Global DC Electric Arc Furnaces Market is poised for significant growth.

Less than 10t, 10-50t, 50-100t, More than 100t in the Global DC Electric Arc Furnaces Market:

In the Global DC Electric Arc Furnaces Market, the categorization based on capacity plays a crucial role in understanding the diverse applications and demands of different industries. Furnaces with a capacity of less than 10 tons are typically used in smaller operations or specialized applications where the volume of metal to be processed is relatively low. These furnaces are ideal for small-scale foundries or workshops that require flexibility and efficiency in melting operations. They offer the advantage of lower initial investment and operational costs, making them accessible to smaller businesses or those with limited production needs. Moving up the scale, furnaces with a capacity of 10 to 50 tons are more suited for medium-sized operations. These furnaces strike a balance between capacity and cost, providing a viable option for companies that need to process moderate volumes of metal. They are often used in industries where the demand for steel or other metals is steady but not overwhelming, such as in certain manufacturing sectors or regional steel mills. The 50 to 100-ton category represents a significant step up in capacity and is typically employed by larger industrial operations. These furnaces are capable of handling substantial volumes of metal, making them suitable for large-scale steel production facilities or major manufacturing plants. The increased capacity allows for greater efficiency and throughput, which is essential for meeting the demands of high-volume production environments. Finally, furnaces with a capacity of more than 100 tons represent the largest segment in the market. These massive furnaces are used by the largest steel producers and are integral to operations where the demand for steel is exceptionally high. They are designed to handle the most significant volumes of metal, providing the efficiency and output necessary to support large-scale industrial activities. The choice of furnace capacity is influenced by several factors, including the scale of operations, the specific requirements of the industry, and the financial resources available. Companies must carefully consider these factors when selecting a furnace to ensure that it aligns with their production goals and operational capabilities. As the Global DC Electric Arc Furnaces Market continues to evolve, the demand for different capacities will be shaped by changes in industrial needs, technological advancements, and economic conditions.

Metal Smelting, Ore Smelting, Others in the Global DC Electric Arc Furnaces Market:

The Global DC Electric Arc Furnaces Market finds its applications in various areas, with metal smelting being one of the primary uses. In metal smelting, these furnaces are employed to melt scrap metal and convert it into liquid steel, which can then be cast into various shapes and forms. The efficiency and cost-effectiveness of DC electric arc furnaces make them a preferred choice for steel producers looking to optimize their operations. The ability to control the melting process precisely allows for the production of high-quality steel with minimal impurities, which is crucial for industries that demand superior material properties. In addition to metal smelting, DC electric arc furnaces are also used in ore smelting. This process involves the extraction of metals from their ores, which requires high temperatures to separate the metal from other elements. DC electric arc furnaces provide the necessary heat and energy to facilitate this process, making them an essential tool in the mining and metallurgical industries. The use of these furnaces in ore smelting helps improve the efficiency and yield of metal extraction, contributing to the overall productivity of mining operations. Beyond metal and ore smelting, DC electric arc furnaces have applications in other areas as well. They are used in the recycling industry to process scrap metal, reducing the need for raw material extraction and promoting sustainability. The ability to recycle metal efficiently helps conserve natural resources and reduce environmental impact, aligning with global efforts to promote sustainable industrial practices. Additionally, these furnaces are used in research and development settings, where they provide a controlled environment for studying high-temperature processes and material properties. The versatility and efficiency of DC electric arc furnaces make them a valuable asset across various industries, supporting a wide range of applications and contributing to the advancement of industrial processes. As the demand for sustainable and efficient production methods continues to grow, the Global DC Electric Arc Furnaces Market is expected to expand, driven by the diverse applications and benefits these furnaces offer.

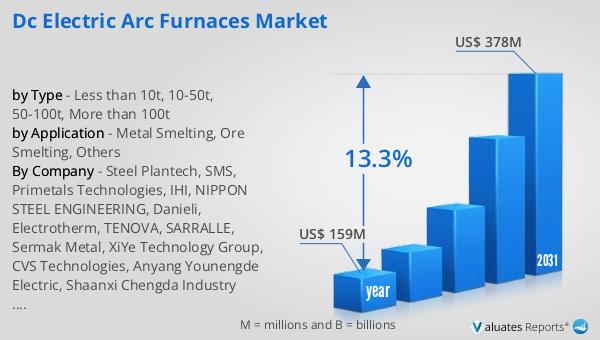

Global DC Electric Arc Furnaces Market Outlook:

In 2024, the global market for DC Electric Arc Furnaces was valued at approximately $159 million. By 2031, it is anticipated to grow significantly, reaching an estimated size of $378 million. This growth represents a compound annual growth rate (CAGR) of 13.3% over the forecast period. Within this market, furnaces with a capacity of more than 100 tons constitute the largest segment, accounting for over 45% of the market share. This indicates a strong demand for high-capacity furnaces, likely driven by large-scale industrial operations that require substantial volumes of steel production. In terms of application, metal smelting emerges as the dominant segment, holding about 70% of the market share. This highlights the critical role that DC electric arc furnaces play in the steelmaking process, where they are used to melt scrap metal and produce liquid steel. The efficiency and cost-effectiveness of these furnaces make them a preferred choice for steel producers, contributing to their widespread adoption in the industry. As the market continues to grow, driven by increasing demand for steel and advancements in furnace technology, the Global DC Electric Arc Furnaces Market is poised for significant expansion.

| Report Metric | Details |

| Report Name | DC Electric Arc Furnaces Market |

| Accounted market size in year | US$ 159 million |

| Forecasted market size in 2031 | US$ 378 million |

| CAGR | 13.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Steel Plantech, SMS, Primetals Technologies, IHI, NIPPON STEEL ENGINEERING, Danieli, Electrotherm, TENOVA, SARRALLE, Sermak Metal, XiYe Technology Group, CVS Technologies, Anyang Younengde Electric, Shaanxi Chengda Industry Furnaces, Jiangsu Lushoon Metallurgical, UkrNIIElectroterm, Zhuzhou Sourthern Inductive Heating Equipment, Zhuzhou Tianyi Electric Furnace |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |