What is Global Continuous Low Pressure Vacuum Carburizing Furnaces Market?

The Global Continuous Low Pressure Vacuum Carburizing Furnaces Market is a specialized segment within the industrial furnace industry, focusing on advanced heat treatment processes. These furnaces are designed to enhance the surface properties of metal components, primarily through a process known as carburizing. Carburizing involves the diffusion of carbon into the surface layer of a metal, typically steel, to improve its hardness and wear resistance. The "continuous" aspect refers to the ability of these furnaces to process materials in a non-stop, streamlined manner, which is crucial for high-volume production environments. The "low pressure" and "vacuum" elements are critical as they help in minimizing oxidation and other unwanted reactions during the heat treatment process, ensuring a cleaner and more controlled environment. This market is driven by the demand for high-performance metal components in various industries, including automotive, aerospace, and manufacturing. The technology is particularly valued for its ability to produce parts with superior mechanical properties, which are essential for applications that require high strength and durability. As industries continue to seek more efficient and effective manufacturing processes, the demand for these advanced furnaces is expected to grow.

Single Chamber, Double Chamber, Multi Chamber in the Global Continuous Low Pressure Vacuum Carburizing Furnaces Market:

In the realm of Global Continuous Low Pressure Vacuum Carburizing Furnaces, the design and configuration of the furnace chambers play a pivotal role in determining the efficiency and effectiveness of the carburizing process. Single Chamber furnaces are the simplest form, where the entire process of heating, carburizing, and cooling occurs within one chamber. This design is typically more compact and cost-effective, making it suitable for smaller operations or those with limited space. However, the single chamber design may limit the throughput and flexibility, as each batch must complete the entire cycle before the next can begin. On the other hand, Double Chamber furnaces introduce a second chamber, allowing for a separation of the heating and cooling processes. This design enhances the efficiency by enabling simultaneous processing of different batches, thus reducing downtime and increasing throughput. The double chamber configuration is particularly beneficial for operations that require a higher volume of production without compromising on quality. Multi Chamber furnaces take this concept further by incorporating multiple chambers, each dedicated to a specific stage of the process. This design maximizes throughput and flexibility, allowing for continuous operation and the ability to handle larger volumes of material. Multi chamber furnaces are ideal for large-scale industrial applications where high efficiency and productivity are paramount. Each chamber can be optimized for its specific function, whether it be heating, carburizing, or cooling, ensuring that each stage of the process is conducted under optimal conditions. This level of specialization and efficiency makes multi chamber furnaces a preferred choice for industries with demanding production requirements. The choice between single, double, and multi chamber designs ultimately depends on the specific needs of the operation, including factors such as production volume, available space, and budget. As the demand for high-quality, durable metal components continues to rise, the importance of selecting the right furnace configuration becomes increasingly critical.

Automotive, Tool & Die, Others in the Global Continuous Low Pressure Vacuum Carburizing Furnaces Market:

The Global Continuous Low Pressure Vacuum Carburizing Furnaces Market finds significant application across various industries, with the automotive sector being one of the primary users. In the automotive industry, these furnaces are essential for producing components that require high strength and wear resistance, such as gears, shafts, and bearings. The carburizing process enhances the surface hardness of these parts, ensuring they can withstand the rigorous demands of automotive applications. This is particularly important as vehicles become more advanced and require components that can endure higher stresses and longer lifespans. The precision and control offered by vacuum carburizing furnaces make them ideal for meeting the stringent quality standards of the automotive industry. In the Tool & Die sector, these furnaces are used to improve the durability and performance of tools and dies, which are critical for manufacturing processes. The enhanced surface properties achieved through carburizing extend the life of these tools, reducing the need for frequent replacements and minimizing downtime. This is crucial for maintaining efficiency and productivity in manufacturing operations. The ability to produce tools with superior mechanical properties also allows manufacturers to achieve higher precision and quality in their products. Beyond automotive and tool & die, the Global Continuous Low Pressure Vacuum Carburizing Furnaces Market serves a variety of other industries, including aerospace, energy, and heavy machinery. In aerospace, the demand for lightweight yet strong components is driving the adoption of advanced heat treatment processes. Vacuum carburizing furnaces are used to produce parts that meet the high-performance requirements of aerospace applications, where safety and reliability are paramount. In the energy sector, these furnaces are used to enhance the performance of components used in power generation and transmission, ensuring they can withstand harsh operating conditions. The versatility and efficiency of continuous low pressure vacuum carburizing furnaces make them a valuable asset across a wide range of industries, each benefiting from the improved material properties and production efficiencies they offer.

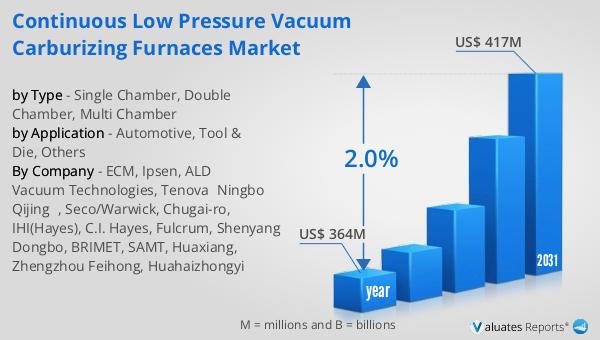

Global Continuous Low Pressure Vacuum Carburizing Furnaces Market Outlook:

The outlook for the Global Continuous Low Pressure Vacuum Carburizing Furnaces Market indicates a steady growth trajectory. In 2024, the market was valued at approximately US$ 364 million. By 2031, it is anticipated to expand to a revised size of US$ 417 million, reflecting a compound annual growth rate (CAGR) of 2.0% over the forecast period. This growth is driven by the increasing demand for high-performance metal components across various industries, including automotive, aerospace, and manufacturing. The continuous advancements in furnace technology, coupled with the need for more efficient and environmentally friendly manufacturing processes, are contributing to the market's expansion. The ability of these furnaces to produce components with superior mechanical properties, while minimizing energy consumption and emissions, makes them an attractive option for industries seeking to enhance their production capabilities. As the market continues to evolve, manufacturers are likely to focus on developing more advanced and cost-effective solutions to meet the growing demand for high-quality metal components. The steady growth of this market underscores the importance of continuous low pressure vacuum carburizing furnaces in modern industrial applications, highlighting their role in driving innovation and efficiency in manufacturing processes.

| Report Metric | Details |

| Report Name | Continuous Low Pressure Vacuum Carburizing Furnaces Market |

| Accounted market size in year | US$ 364 million |

| Forecasted market size in 2031 | US$ 417 million |

| CAGR | 2.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ECM, Ipsen, ALD Vacuum Technologies, Tenova(Ningbo Qijing), Seco/Warwick, Chugai-ro, IHI(Hayes), C.I. Hayes, Fulcrum, Shenyang Dongbo, BRIMET, SAMT, Huaxiang, Zhengzhou Feihong, Huahaizhongyi |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |