What is Global Ultrasonic Flaw Detection Equipment Market?

The Global Ultrasonic Flaw Detection Equipment Market is a specialized segment within the broader non-destructive testing (NDT) industry. This market focuses on equipment that uses ultrasonic waves to detect flaws or defects in materials without causing any damage. Ultrasonic flaw detection is a critical process in various industries, ensuring the integrity and safety of materials and structures. The equipment works by sending high-frequency sound waves into a material and analyzing the reflected waves to identify any discontinuities or imperfections. This technology is widely used because it is highly accurate, reliable, and can be applied to a wide range of materials, including metals, plastics, and composites. The market for ultrasonic flaw detection equipment is driven by the increasing demand for quality assurance and safety in industries such as manufacturing, aerospace, automotive, and oil and gas. As industries continue to prioritize safety and efficiency, the demand for advanced ultrasonic flaw detection equipment is expected to grow. The market is characterized by continuous technological advancements, with manufacturers focusing on developing more sophisticated and user-friendly equipment to meet the evolving needs of various industries.

Conventional Ultrasonic Flaw Detection Equipment, Phased Array Ultrasonic Flaw Detection Equipment, TOFD Ultrasonic Flaw Detection Equipment in the Global Ultrasonic Flaw Detection Equipment Market:

Conventional Ultrasonic Flaw Detection Equipment is one of the primary types of equipment used in the Global Ultrasonic Flaw Detection Equipment Market. This type of equipment utilizes traditional ultrasonic testing methods, where a transducer sends ultrasonic waves into a material, and the reflected waves are analyzed to detect any flaws. Conventional ultrasonic flaw detectors are widely used due to their simplicity, reliability, and cost-effectiveness. They are suitable for a variety of applications, including weld inspection, thickness measurement, and material characterization. These devices are often portable, making them ideal for field inspections and on-site testing. Despite being a traditional method, conventional ultrasonic flaw detection remains popular due to its proven track record and ease of use.

Manufacturing and Machinery Industry, Aerospace Industry, Automotive Industry, Oil & Gas Industry, Railways, Others in the Global Ultrasonic Flaw Detection Equipment Market:

Phased Array Ultrasonic Flaw Detection Equipment represents a more advanced form of ultrasonic testing. This technology uses multiple ultrasonic elements and electronic time delays to create a focused beam of sound waves. The phased array technique allows for more precise control over the direction and focus of the ultrasonic beam, enabling detailed imaging of the material being tested. This results in higher accuracy and the ability to detect smaller flaws compared to conventional methods. Phased array ultrasonic flaw detectors are particularly useful in complex inspections, such as those involving intricate geometries or difficult-to-access areas. They are commonly used in industries where precision and reliability are paramount, such as aerospace and oil and gas. The ability to generate detailed images and data makes phased array equipment a valuable tool for engineers and inspectors seeking to ensure the highest levels of safety and quality.

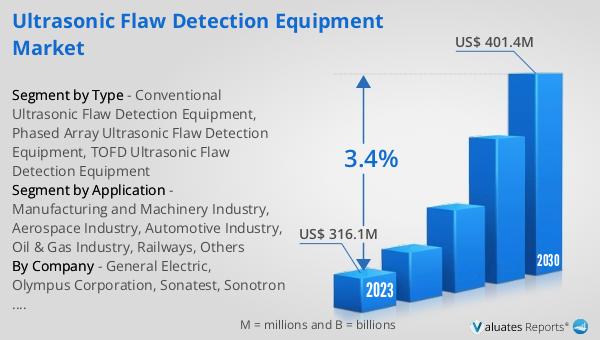

Global Ultrasonic Flaw Detection Equipment Market Outlook:

Time of Flight Diffraction (TOFD) Ultrasonic Flaw Detection Equipment is another sophisticated method used in the market. TOFD is a technique that measures the time it takes for ultrasonic waves to travel through a material and return after encountering a flaw. Unlike other methods, TOFD does not rely on the amplitude of the reflected waves but rather on the time of flight, making it highly accurate in detecting and sizing defects. This method is particularly effective for inspecting welds and detecting cracks, as it provides a comprehensive view of the material's internal structure. TOFD is often used in conjunction with other ultrasonic testing methods to provide a complete assessment of a material's integrity. Its ability to accurately size defects makes it a preferred choice for critical applications where safety is a top priority.

| Report Metric | Details |

| Report Name | Ultrasonic Flaw Detection Equipment Market |

| Accounted market size in year | US$ 339 million |

| Forecasted market size in 2031 | US$ 426 million |

| CAGR | 3.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | General Electric, Olympus Corporation, Sonatest, Sonotron NDT, Zetec, Kropus, Hitachi Power Solutions, Dakota Ultrasonics, Modsonic karldeutsch |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |