What is Global Vacuum Wafer Chucks Market?

The Global Vacuum Wafer Chucks Market is a specialized segment within the semiconductor industry, focusing on the production and distribution of vacuum wafer chucks. These chucks are essential tools used in the manufacturing and processing of semiconductor wafers. They function by securely holding the wafers in place during various stages of production, such as etching, deposition, and inspection. The vacuum mechanism ensures that the wafers remain stable and precisely positioned, which is crucial for maintaining the high levels of accuracy and quality required in semiconductor manufacturing. The market for vacuum wafer chucks is driven by the increasing demand for semiconductors across various industries, including electronics, automotive, and telecommunications. As technology advances and the need for smaller, more efficient electronic components grows, the demand for high-quality wafer chucks is expected to rise. This market is characterized by continuous innovation, with manufacturers striving to develop chucks that offer improved performance, reliability, and compatibility with different wafer sizes and materials. Overall, the Global Vacuum Wafer Chucks Market plays a vital role in supporting the semiconductor industry's growth and technological advancements.

300 mm Wafer, 200 mm Wafer, Others in the Global Vacuum Wafer Chucks Market:

In the Global Vacuum Wafer Chucks Market, wafer sizes such as 300 mm, 200 mm, and others play a significant role in determining the market dynamics and product offerings. The 300 mm wafer is the largest segment within this market, accounting for over 70% of the product share. This dominance is primarily due to the efficiency and cost-effectiveness associated with larger wafers. A 300 mm wafer can accommodate more chips than smaller wafers, leading to higher production yields and reduced manufacturing costs per chip. This size is particularly favored in high-volume production environments where maximizing output and minimizing costs are critical. The 200 mm wafer, while smaller, still holds a substantial portion of the market. It is often used in the production of specialized or niche semiconductor products where the demand does not justify the use of larger wafers. The 200 mm wafer is also prevalent in older manufacturing facilities that have not yet transitioned to the larger 300 mm technology. Despite being smaller, these wafers are crucial for producing certain types of semiconductors that require specific manufacturing processes or materials. Other wafer sizes, although less common, are also part of the Global Vacuum Wafer Chucks Market. These include wafers used for research and development purposes, as well as those designed for specialized applications in emerging technologies. As the semiconductor industry continues to evolve, the demand for various wafer sizes will likely shift, influenced by technological advancements and changing market needs. Manufacturers of vacuum wafer chucks must remain adaptable, offering products that cater to the diverse requirements of different wafer sizes and applications. The ability to provide high-quality, reliable chucks for a range of wafer sizes is essential for maintaining competitiveness in this dynamic market.

Wafer Suppliers, Semiconductor Equipment Suppliers in the Global Vacuum Wafer Chucks Market:

The Global Vacuum Wafer Chucks Market serves a critical function in the semiconductor industry, particularly for wafer suppliers and semiconductor equipment suppliers. For wafer suppliers, vacuum wafer chucks are indispensable tools that ensure the precision and quality of their products. These suppliers rely on vacuum chucks to securely hold wafers during various stages of production, such as slicing, polishing, and inspection. The stability provided by the vacuum mechanism is crucial for maintaining the integrity of the wafers, preventing damage, and ensuring that they meet the stringent quality standards required by their customers. As wafer suppliers strive to produce increasingly smaller and more complex semiconductor devices, the demand for advanced vacuum wafer chucks that can accommodate these requirements continues to grow. Semiconductor equipment suppliers also benefit significantly from the Global Vacuum Wafer Chucks Market. These suppliers provide the machinery and tools used in the semiconductor manufacturing process, and vacuum wafer chucks are a vital component of their offerings. By integrating high-quality vacuum chucks into their equipment, these suppliers can enhance the performance and reliability of their machines, providing added value to their customers. The precision and stability offered by vacuum wafer chucks are essential for ensuring that semiconductor manufacturing equipment operates at optimal efficiency, reducing the risk of errors and improving overall production yields. As the semiconductor industry continues to advance, equipment suppliers must keep pace by offering cutting-edge solutions that incorporate the latest vacuum chuck technologies. This includes developing chucks that are compatible with a wide range of wafer sizes and materials, as well as those that can withstand the demanding conditions of modern semiconductor manufacturing environments. By doing so, they can maintain their competitive edge and meet the evolving needs of their customers in this rapidly changing market.

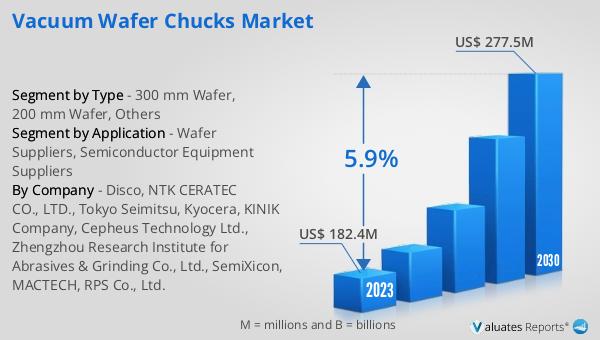

Global Vacuum Wafer Chucks Market Outlook:

The global market for Vacuum Wafer Chucks was valued at $208 million in 2024 and is anticipated to expand to a revised size of $308 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.9% throughout the forecast period. Within this market, the 300 mm wafer segment emerges as the largest, capturing over 70% of the product share. This dominance underscores the efficiency and cost-effectiveness of larger wafers, which are capable of accommodating more chips, thereby enhancing production yields and reducing manufacturing costs per chip. In terms of distribution channels, wafer suppliers represent the largest segment, accounting for approximately 80% of the market share. This highlights the critical role that wafer suppliers play in the distribution and utilization of vacuum wafer chucks, as they rely heavily on these tools to ensure the precision and quality of their semiconductor products. The significant market share held by wafer suppliers also reflects the growing demand for semiconductors across various industries, driving the need for advanced vacuum wafer chucks that can support the production of increasingly complex and miniaturized electronic components. As the market continues to evolve, manufacturers and suppliers must remain agile, adapting to changing technological trends and customer requirements to sustain growth and competitiveness in this dynamic industry.

| Report Metric | Details |

| Report Name | Vacuum Wafer Chucks Market |

| Accounted market size in year | US$ 208 million |

| Forecasted market size in 2031 | US$ 308 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Disco, NTK CERATEC CO., LTD., Tokyo Seimitsu, Kyocera, KINIK Company, Cepheus Technology Ltd., Zhengzhou Research Institute for Abrasives & Grinding Co., Ltd., SemiXicon, MACTECH, RPS Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |