What is Global Clad Steel Plate Market?

The Global Clad Steel Plate Market is a significant segment within the broader steel industry, characterized by its specialized production of clad steel plates. These plates are essentially composite materials made by bonding two different metals, typically a corrosion-resistant alloy and a structural steel, to enhance the properties of the base material. This process results in a product that combines the strength and durability of steel with the corrosion resistance of the alloy, making it ideal for various demanding applications. The market for clad steel plates is driven by industries that require materials capable of withstanding harsh environments, such as oil and gas, chemical processing, and water treatment. The demand for these plates is also influenced by the need for cost-effective solutions that do not compromise on performance. As industries continue to seek materials that offer both economic and functional benefits, the global clad steel plate market is expected to grow, driven by technological advancements and increasing applications across various sectors. The market's growth is further supported by the ongoing development of new bonding techniques and materials, which enhance the performance and applicability of clad steel plates in diverse industrial settings.

Explosion Bonded Clad Plate, Roll Bonded Clad Plate in the Global Clad Steel Plate Market:

Explosion Bonded Clad Plate and Roll Bonded Clad Plate are two prominent types of clad steel plates that play a crucial role in the Global Clad Steel Plate Market. Explosion bonded clad plates are created through a process that involves the use of controlled explosive energy to bond two dissimilar metals. This method is particularly effective for joining metals that are otherwise difficult to weld using conventional techniques. The explosion bonding process results in a metallurgical bond that is exceptionally strong and durable, making it suitable for applications where high pressure and temperature conditions are prevalent. This type of clad plate is widely used in industries such as oil and gas, where the materials are exposed to corrosive environments and extreme conditions. The explosion bonding technique allows for the creation of large, complex shapes, which is advantageous for manufacturing components like pressure vessels and heat exchangers. On the other hand, roll bonded clad plates are produced through a different process that involves rolling two metals together under high pressure and temperature. This method is more suited for creating large, flat plates and is often used when the metals involved have similar thermal expansion properties. Roll bonding is a cost-effective method for producing clad plates and is commonly used in applications where large surface areas are required, such as in the construction of storage tanks and large industrial equipment. The roll bonding process ensures a uniform bond across the entire surface of the plate, providing consistent performance and reliability. Both explosion bonded and roll bonded clad plates offer unique advantages and are chosen based on the specific requirements of the application. Explosion bonded plates are preferred for their ability to join dissimilar metals and create complex shapes, while roll bonded plates are favored for their cost-effectiveness and suitability for large-scale applications. The choice between these two types of clad plates depends on factors such as the intended use, the properties of the metals involved, and the economic considerations of the project. In the Global Clad Steel Plate Market, the demand for these products is driven by the need for materials that can withstand harsh environments and provide long-lasting performance. Industries such as oil and gas, chemical processing, and water treatment rely heavily on clad steel plates to ensure the safety and efficiency of their operations. As these industries continue to grow and evolve, the demand for high-quality clad steel plates is expected to increase, further driving innovation and development within the market. The ongoing advancements in bonding techniques and materials are likely to enhance the performance and applicability of clad steel plates, making them an increasingly important component in a wide range of industrial applications.

Oil & Gas, Chemical Industry, Water Treatment, Others in the Global Clad Steel Plate Market:

The Global Clad Steel Plate Market finds extensive usage across various industries, including oil and gas, chemical processing, water treatment, and others, due to its unique properties and advantages. In the oil and gas industry, clad steel plates are essential for constructing pipelines, pressure vessels, and storage tanks that must withstand corrosive environments and high-pressure conditions. The ability of clad plates to resist corrosion and maintain structural integrity under extreme conditions makes them an ideal choice for offshore platforms and refineries, where safety and reliability are paramount. The use of clad steel plates in this sector helps to extend the lifespan of critical infrastructure, reduce maintenance costs, and ensure the safe transport and storage of oil and gas products. In the chemical industry, clad steel plates are used to manufacture reactors, heat exchangers, and other equipment that must endure aggressive chemical environments. The corrosion-resistant properties of clad plates make them suitable for handling a wide range of chemicals, including acids and alkalis, which can cause significant damage to conventional materials. By using clad steel plates, chemical processing facilities can enhance the durability and efficiency of their equipment, minimize downtime, and improve overall operational safety. The versatility of clad plates allows them to be tailored to specific chemical processes, ensuring optimal performance and longevity. Water treatment facilities also benefit from the use of clad steel plates, particularly in the construction of desalination plants, filtration systems, and storage tanks. The ability of clad plates to resist corrosion and withstand harsh environmental conditions makes them ideal for use in water treatment applications, where exposure to saltwater and other corrosive elements is common. By incorporating clad steel plates into their infrastructure, water treatment facilities can improve the reliability and efficiency of their operations, reduce maintenance requirements, and ensure the delivery of clean, safe water to communities. Beyond these primary industries, clad steel plates are also used in a variety of other applications, including power generation, shipbuilding, and infrastructure development. In power generation, clad plates are used to construct boilers and turbines that must operate under high temperatures and pressures. In shipbuilding, they are used to create hulls and other components that require enhanced corrosion resistance and structural strength. The versatility and performance of clad steel plates make them a valuable asset in any industry that demands materials capable of withstanding challenging conditions and providing long-term reliability. Overall, the Global Clad Steel Plate Market plays a vital role in supporting the infrastructure and operations of numerous industries worldwide. The unique properties of clad steel plates, combined with their cost-effectiveness and adaptability, make them an indispensable component in the construction and maintenance of critical industrial equipment and facilities. As industries continue to evolve and face new challenges, the demand for high-quality clad steel plates is expected to grow, driving further innovation and development within the market.

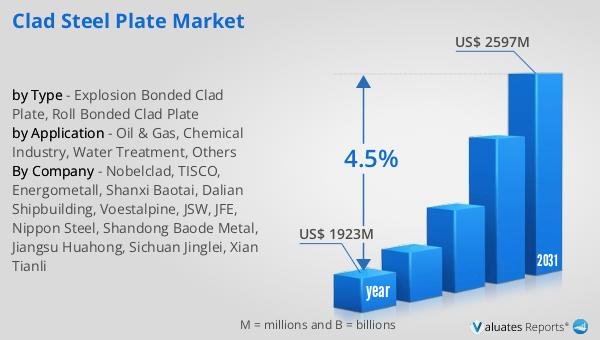

Global Clad Steel Plate Market Outlook:

The global market for Clad Steel Plate was valued at approximately $1,923 million in 2024, with projections indicating a growth to around $2,597 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 4.5% over the forecast period. Within this market, the explosion bonded clad plate segment stands out as the largest, accounting for over 60% of the market share. This dominance is attributed to the unique advantages offered by explosion bonded clad plates, such as their ability to join dissimilar metals and create complex shapes, which are highly valued in industries like oil and gas and chemical processing. The robust growth of the market is driven by the increasing demand for materials that offer both strength and corrosion resistance, as well as the ongoing development of new bonding techniques and materials. As industries continue to seek cost-effective solutions that do not compromise on performance, the global clad steel plate market is poised for continued expansion. The market's growth is further supported by the rising need for infrastructure development and the modernization of industrial facilities, which require high-quality materials capable of withstanding harsh environments and providing long-lasting performance.

| Report Metric | Details |

| Report Name | Clad Steel Plate Market |

| Accounted market size in year | US$ 1923 million |

| Forecasted market size in 2031 | US$ 2597 million |

| CAGR | 4.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nobelclad, TISCO, Energometall, Shanxi Baotai, Dalian Shipbuilding, Voestalpine, JSW, JFE, Nippon Steel, Shandong Baode Metal, Jiangsu Huahong, Sichuan Jinglei, Xian Tianli |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |