What is Global Electroforming Molds Market?

The Global Electroforming Molds Market is a specialized segment within the manufacturing industry that focuses on the production of high-precision molds through the electroforming process. Electroforming is a metal forming process that involves the deposition of metal onto a mold to create intricate and precise shapes. This market is driven by the demand for high-quality molds used in various industries such as automotive, aerospace, consumer goods, and electronics. The process allows for the creation of molds with complex geometries and fine details, which are difficult to achieve with traditional manufacturing methods. The global market for electroforming molds is characterized by technological advancements, increasing demand for precision components, and the need for cost-effective manufacturing solutions. Companies operating in this market are continuously investing in research and development to improve the efficiency and quality of electroforming processes. The market is also influenced by factors such as the availability of raw materials, regulatory standards, and the overall economic environment. As industries continue to seek innovative solutions for manufacturing challenges, the demand for electroforming molds is expected to grow, offering opportunities for market expansion and technological advancements.

Copper, Nickel, Iron, Others in the Global Electroforming Molds Market:

In the Global Electroforming Molds Market, materials such as copper, nickel, iron, and others play a crucial role in the manufacturing process. Copper is widely used due to its excellent electrical conductivity, thermal properties, and ease of electroforming. It is often chosen for applications requiring high precision and fine details, making it a popular choice in industries like electronics and telecommunications. Nickel, on the other hand, is valued for its hardness, corrosion resistance, and ability to produce durable molds. It is commonly used in applications where strength and longevity are essential, such as in the aerospace and automotive industries. Iron, although less commonly used than copper and nickel, offers unique benefits such as magnetic properties and cost-effectiveness. It is often utilized in applications where magnetic characteristics are required or where budget constraints are a concern. Other materials, including alloys and composites, are also used in the electroforming process to achieve specific properties or to meet particular industry requirements. The choice of material depends on factors such as the intended application, desired properties, and cost considerations. Each material offers distinct advantages and challenges, influencing the overall performance and quality of the electroformed molds. As the market continues to evolve, the development of new materials and advancements in electroforming technology are expected to enhance the capabilities and applications of electroforming molds, providing manufacturers with more options and flexibility in their production processes.

Automotive, Industrial, Consumer Goods, Aerospace & Defense, Others in the Global Electroforming Molds Market:

The Global Electroforming Molds Market finds applications across various industries, including automotive, industrial, consumer goods, aerospace and defense, and others. In the automotive sector, electroforming molds are used to produce components with high precision and intricate designs, such as grilles, emblems, and interior trim parts. The ability to create lightweight and durable components is crucial in this industry, where performance and aesthetics are equally important. In the industrial sector, electroforming molds are utilized for manufacturing tools, dies, and other equipment that require high accuracy and durability. The process allows for the production of complex shapes and fine details, which are essential in industries such as electronics, telecommunications, and medical devices. In the consumer goods industry, electroforming molds are used to create products with intricate designs and high-quality finishes, such as jewelry, watches, and decorative items. The ability to produce detailed and aesthetically pleasing products is a significant advantage in this market, where consumer preferences and trends play a crucial role. In the aerospace and defense industry, electroforming molds are used to manufacture components that require high precision, strength, and resistance to extreme conditions. The process allows for the production of lightweight and durable parts, which are essential in applications such as aircraft engines, missile systems, and satellite components. Other industries, such as energy, construction, and healthcare, also benefit from the advantages of electroforming molds, as they offer solutions for complex manufacturing challenges and enable the production of high-quality components. As the demand for precision and innovation continues to grow across various sectors, the Global Electroforming Molds Market is expected to expand, offering new opportunities for manufacturers and driving advancements in electroforming technology.

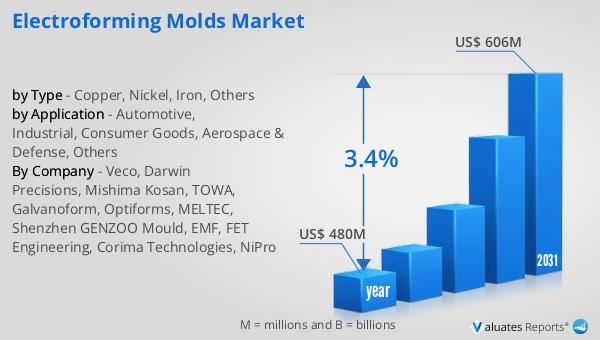

Global Electroforming Molds Market Outlook:

The global market for electroforming molds was valued at approximately $480 million in 2024 and is anticipated to grow to a revised size of $606 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.4% over the forecast period. The market is dominated by the top five manufacturers, namely Veco, Darwin Precisions, Mishima Kosan, TOWA, and Galvanoform, which collectively hold a market share exceeding 30%. Among these, Veco stands out as the largest manufacturer, with a market share surpassing 12%. The Asia-Pacific region emerges as the most significant consumer market for electroforming molds globally, accounting for over 40% of sales. In terms of material type, copper holds a substantial market share of over 47%, highlighting its prominence in the industry. The market dynamics are shaped by factors such as technological advancements, increasing demand for precision components, and the need for cost-effective manufacturing solutions. As industries continue to seek innovative solutions for manufacturing challenges, the demand for electroforming molds is expected to grow, offering opportunities for market expansion and technological advancements.

| Report Metric | Details |

| Report Name | Electroforming Molds Market |

| Accounted market size in year | US$ 480 million |

| Forecasted market size in 2031 | US$ 606 million |

| CAGR | 3.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Veco, Darwin Precisions, Mishima Kosan, TOWA, Galvanoform, Optiforms, MELTEC, Shenzhen GENZOO Mould, EMF, FET Engineering, Corima Technologies, NiPro |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |