What is Global High Pressure Isolation Valves Market?

The Global High Pressure Isolation Valves Market is a specialized segment within the broader industrial valves industry, focusing on valves designed to withstand and operate under high-pressure conditions. These valves are crucial components in various industrial applications where the control and isolation of fluid flow are necessary under extreme pressure. High pressure isolation valves are engineered to provide reliable performance and safety, ensuring that fluids can be effectively managed without leaks or failures. They are used in industries such as oil and gas, power generation, chemical processing, and water treatment, where the ability to handle high pressure is essential for operational efficiency and safety. The market for these valves is driven by the increasing demand for energy and the need for efficient fluid control systems in industrial processes. Technological advancements and the development of new materials have also contributed to the growth of this market, enabling the production of valves that can withstand higher pressures and more demanding conditions. As industries continue to expand and modernize, the demand for high pressure isolation valves is expected to grow, making this a dynamic and evolving market segment.

Ball Valves, Gate Valves, Butterfly Valves, Globe Valves, Others in the Global High Pressure Isolation Valves Market:

Ball valves, gate valves, butterfly valves, globe valves, and other types of valves each play a unique role in the Global High Pressure Isolation Valves Market, catering to different industrial needs and applications. Ball valves are known for their durability and excellent shut-off capabilities. They use a spherical disc to control the flow of fluids, making them ideal for applications requiring a tight seal and quick operation. Their design allows for minimal leakage and they are often used in situations where a reliable and robust valve is necessary. Gate valves, on the other hand, are primarily used for on/off control of fluid flow. They operate by lifting a gate out of the path of the fluid, providing a clear and unobstructed passage. This makes them suitable for applications where a straight-line flow of fluid and minimum restriction is desired. Butterfly valves are characterized by their compact design and quick operation. They use a rotating disc to regulate the flow of fluids and are often used in applications where space is limited and a lightweight valve is needed. Their simple design makes them cost-effective and easy to maintain. Globe valves are used for regulating flow in a pipeline, offering precise control over fluid flow. They are designed with a movable disk-type element and a stationary ring seat in a generally spherical body. This design allows for excellent throttling capabilities, making them ideal for applications where flow regulation is critical. Other types of valves in the high pressure isolation market include plug valves, needle valves, and diaphragm valves, each offering specific advantages for particular applications. Plug valves are known for their simple design and ease of operation, making them suitable for quick shut-off applications. Needle valves provide precise control of flow, making them ideal for applications requiring fine adjustments. Diaphragm valves are used in applications where contamination must be minimized, as they provide a clean and leak-proof seal. Each type of valve in the high pressure isolation market is designed to meet specific industrial requirements, ensuring that fluids can be controlled and managed effectively under high-pressure conditions.

Oil and Gas, Power Generation, Chemical, Water Treatment, Others in the Global High Pressure Isolation Valves Market:

The usage of Global High Pressure Isolation Valves Market spans across various industries, each with its unique requirements and challenges. In the oil and gas industry, high pressure isolation valves are essential for controlling the flow of crude oil and natural gas through pipelines and processing facilities. These valves must withstand extreme pressures and harsh environmental conditions, ensuring the safe and efficient transport of hydrocarbons. They are used in upstream, midstream, and downstream operations, playing a critical role in maintaining the integrity of the infrastructure and preventing leaks or spills. In power generation, high pressure isolation valves are used in steam and water systems to control the flow of fluids within power plants. They are crucial for maintaining the efficiency and safety of the power generation process, ensuring that steam and water are effectively managed to optimize energy production. These valves must be able to withstand high temperatures and pressures, making them a vital component in both conventional and renewable energy power plants. The chemical industry relies on high pressure isolation valves to manage the flow of various chemicals and gases used in production processes. These valves must be resistant to corrosion and chemical attack, ensuring that they can operate reliably in aggressive environments. They are used in applications such as chemical reactors, storage tanks, and pipelines, where precise control of fluid flow is necessary to ensure product quality and safety. In water treatment, high pressure isolation valves are used to control the flow of water and other fluids through treatment plants and distribution systems. They are essential for maintaining the efficiency and reliability of water treatment processes, ensuring that clean and safe water is delivered to consumers. These valves must be able to handle varying pressures and flow rates, making them a critical component in both municipal and industrial water treatment systems. Other industries, such as pharmaceuticals, food and beverage, and mining, also utilize high pressure isolation valves to manage fluid flow in their operations. Each industry has specific requirements for valve performance, and manufacturers continue to innovate and develop new solutions to meet these demands. As industries evolve and new challenges arise, the role of high pressure isolation valves in ensuring safe and efficient fluid management becomes increasingly important.

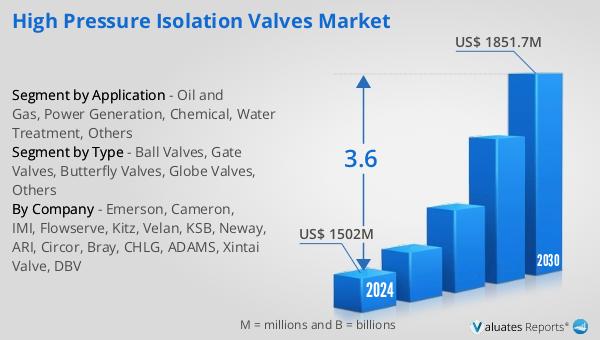

Global High Pressure Isolation Valves Market Outlook:

The global market for High Pressure Isolation Valves was valued at $1,550 million in 2024 and is anticipated to expand to a revised size of $1,972 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.6% over the forecast period. This growth trajectory underscores the increasing demand for high pressure isolation valves across various industries, driven by the need for efficient and reliable fluid control systems. The market is characterized by the dominance of the top three manufacturers, who collectively hold a market share exceeding 40%. This concentration of market power highlights the competitive nature of the industry and the importance of innovation and quality in maintaining market leadership. Among the different types of valves, ball valves represent the largest segment, accounting for over 30% of the market share. This is indicative of their widespread use and versatility in handling high-pressure applications. Ball valves are favored for their durability, ease of operation, and ability to provide a tight seal, making them a preferred choice in industries such as oil and gas, power generation, and chemical processing. The market outlook for high pressure isolation valves is shaped by several factors, including technological advancements, regulatory requirements, and the ongoing need for energy and resource efficiency. As industries continue to modernize and expand, the demand for high-quality valves that can withstand extreme conditions is expected to grow, driving further innovation and development in this dynamic market segment.

| Report Metric | Details |

| Report Name | High Pressure Isolation Valves Market |

| Accounted market size in year | US$ 1550 million |

| Forecasted market size in 2031 | US$ 1972 million |

| CAGR | 3.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Emerson, Cameron, IMI, Flowserve, Kitz, Velan, KSB, Neway, ARI, Circor, Bray, CHLG, ADAMS, Xintai Valve, DBV |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |