What is Global Engineering Plastics Recycling Market?

The Global Engineering Plastics Recycling Market is a rapidly evolving sector that focuses on the recovery and reuse of engineering plastics, which are high-performance materials used in a variety of applications due to their superior mechanical and thermal properties. These plastics include polycarbonate (PC), polyoxymethylene (POM), polymethyl methacrylate (PMMA), polyether ether ketone (PEEK), polyamide (PA), polybutylene terephthalate (PBT), and polyphenylene sulfide (PPS), among others. The recycling process involves collecting, sorting, cleaning, and reprocessing these plastics to produce new materials that can be used in manufacturing. This market is driven by the increasing demand for sustainable and eco-friendly materials, as well as stringent regulations aimed at reducing plastic waste and promoting recycling. The market is also influenced by technological advancements in recycling processes, which enhance the efficiency and quality of recycled plastics. As industries across the globe strive to reduce their carbon footprint and embrace circular economy principles, the Global Engineering Plastics Recycling Market is poised for significant growth, offering both environmental benefits and economic opportunities.

PC, POM, PMMA, PEEK, PA, PBT, PPS, Others in the Global Engineering Plastics Recycling Market:

In the Global Engineering Plastics Recycling Market, various types of engineering plastics are recycled, each with unique properties and applications. Polycarbonate (PC) is known for its high impact resistance and optical clarity, making it ideal for applications such as eyewear lenses, automotive components, and electronic devices. Recycling PC involves processes that maintain its clarity and strength, allowing it to be reused in similar applications. Polyoxymethylene (POM), also known as acetal, is valued for its high stiffness, low friction, and excellent dimensional stability. It is commonly used in precision parts like gears and bearings. Recycling POM requires careful handling to preserve its mechanical properties, ensuring it can be effectively reused in demanding applications. Polymethyl methacrylate (PMMA), often referred to as acrylic, is prized for its transparency and weather resistance. It is used in products like signage, displays, and lighting fixtures. The recycling of PMMA focuses on maintaining its clarity and UV resistance, enabling its reuse in similar applications. Polyether ether ketone (PEEK) is a high-performance thermoplastic known for its exceptional chemical resistance and mechanical properties at elevated temperatures. It is used in aerospace, automotive, and medical applications. Recycling PEEK involves advanced processes to retain its high-performance characteristics, allowing it to be reused in critical applications. Polyamide (PA), commonly known as nylon, is used in textiles, automotive components, and industrial applications due to its strength and flexibility. Recycling PA involves processes that maintain its tensile strength and elasticity, enabling its reuse in similar applications. Polybutylene terephthalate (PBT) is known for its electrical resistance and dimensional stability, making it suitable for electronic components and automotive parts. Recycling PBT focuses on preserving its electrical properties and stability, allowing it to be reused in similar applications. Polyphenylene sulfide (PPS) is a high-performance plastic known for its chemical resistance and thermal stability. It is used in automotive, electrical, and industrial applications. Recycling PPS involves processes that maintain its chemical and thermal properties, enabling its reuse in demanding environments. Other engineering plastics, such as thermoplastic elastomers and liquid crystal polymers, are also recycled in this market, each requiring specific processes to preserve their unique properties. The recycling of these plastics not only reduces waste but also conserves resources and energy, contributing to a more sustainable and circular economy.

Package, Building Construction, Automobile, Electronic Appliances, Others in the Global Engineering Plastics Recycling Market:

The Global Engineering Plastics Recycling Market plays a crucial role in various industries, including packaging, building construction, automotive, electronic appliances, and others. In the packaging industry, recycled engineering plastics are used to produce durable and lightweight packaging materials that offer excellent protection and sustainability. These materials are ideal for food packaging, consumer goods, and industrial applications, where they help reduce environmental impact and meet regulatory requirements for sustainability. In the building construction sector, recycled engineering plastics are used in applications such as insulation, piping, and structural components. These materials offer benefits such as durability, resistance to weathering, and ease of installation, making them ideal for sustainable building practices. The use of recycled plastics in construction helps reduce the carbon footprint of buildings and supports the development of green infrastructure. In the automotive industry, recycled engineering plastics are used in the production of lightweight and high-performance components, such as bumpers, dashboards, and interior trims. These materials help improve fuel efficiency and reduce emissions, contributing to the industry's sustainability goals. The use of recycled plastics in automotive applications also supports the circular economy by reducing waste and conserving resources. In the electronic appliances sector, recycled engineering plastics are used in the production of durable and high-performance components, such as housings, connectors, and circuit boards. These materials offer benefits such as electrical insulation, thermal stability, and resistance to chemicals, making them ideal for electronic applications. The use of recycled plastics in electronics helps reduce e-waste and supports the industry's sustainability initiatives. Other industries, such as healthcare, aerospace, and consumer goods, also benefit from the use of recycled engineering plastics, which offer a combination of performance, sustainability, and cost-effectiveness. The Global Engineering Plastics Recycling Market is essential for promoting sustainable practices across various industries, reducing environmental impact, and supporting the transition to a circular economy.

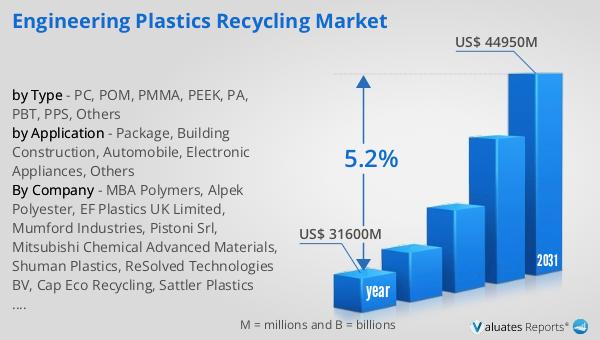

Global Engineering Plastics Recycling Market Outlook:

The outlook for the Global Engineering Plastics Recycling Market is promising, with significant growth expected in the coming years. In 2024, the market was valued at approximately US$ 31,600 million, and it is anticipated to expand to a revised size of US$ 44,950 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.2% over the forecast period. This growth is driven by increasing demand for sustainable materials and advancements in recycling technologies. In 2021, the recycling volume reached 19 million tons, with a recycling rate of 31%, highlighting the progress made in plastic recycling, particularly in China. China's achievements in this area are noteworthy, as the country has implemented effective policies and technologies to enhance recycling rates and reduce plastic waste. The market's expansion is supported by growing awareness of environmental issues and the need for sustainable solutions across various industries. As more companies and consumers prioritize sustainability, the demand for recycled engineering plastics is expected to rise, driving further growth in the market. The Global Engineering Plastics Recycling Market is poised to play a vital role in promoting sustainability and reducing the environmental impact of plastic waste, offering significant opportunities for innovation and development.

| Report Metric | Details |

| Report Name | Engineering Plastics Recycling Market |

| Accounted market size in year | US$ 31600 million |

| Forecasted market size in 2031 | US$ 44950 million |

| CAGR | 5.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MBA Polymers, Alpek Polyester, EF Plastics UK Limited, Mumford Industries, Pistoni Srl, Mitsubishi Chemical Advanced Materials, Shuman Plastics, ReSolved Technologies BV, Cap Eco Recycling, Sattler Plastics Company, Kingfa Technology, Chongqing Gengye New Material Technology, Ruimo Environmental Protection New Material, Tian Qiang Environmental Protection Technology, Longshun Plastics, Covestro Plastic Technology, Plitter, Rising Sun Hongyu Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |